Seawater desalination corrosion test method

A corrosion test, seawater technology, applied in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve problems such as overweight design, increased equipment cost, thickened corrosion allowance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

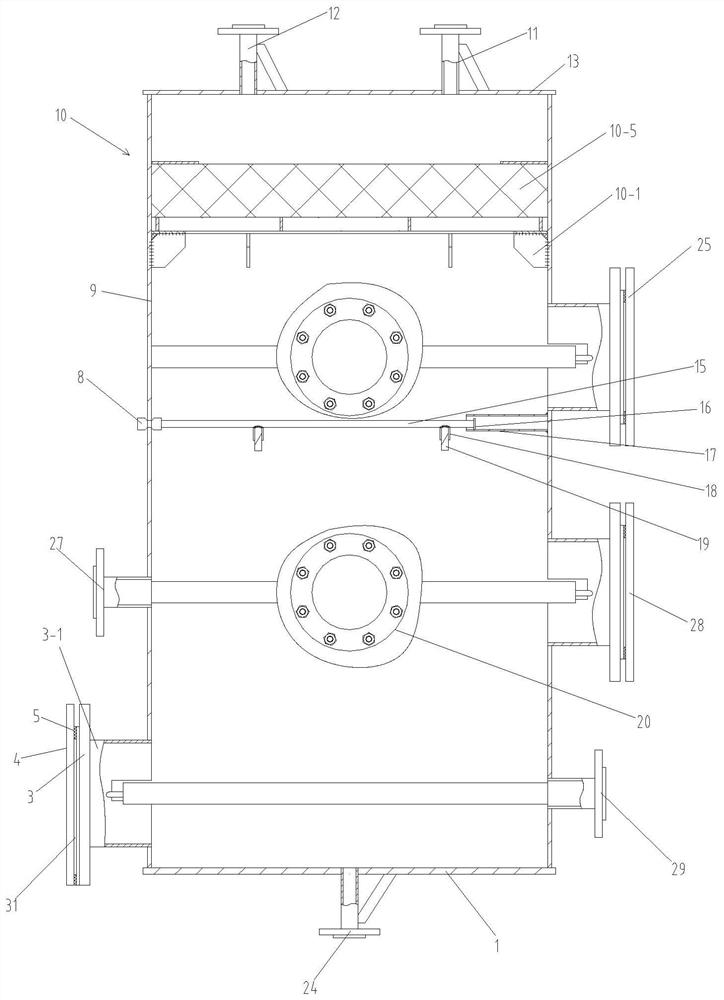

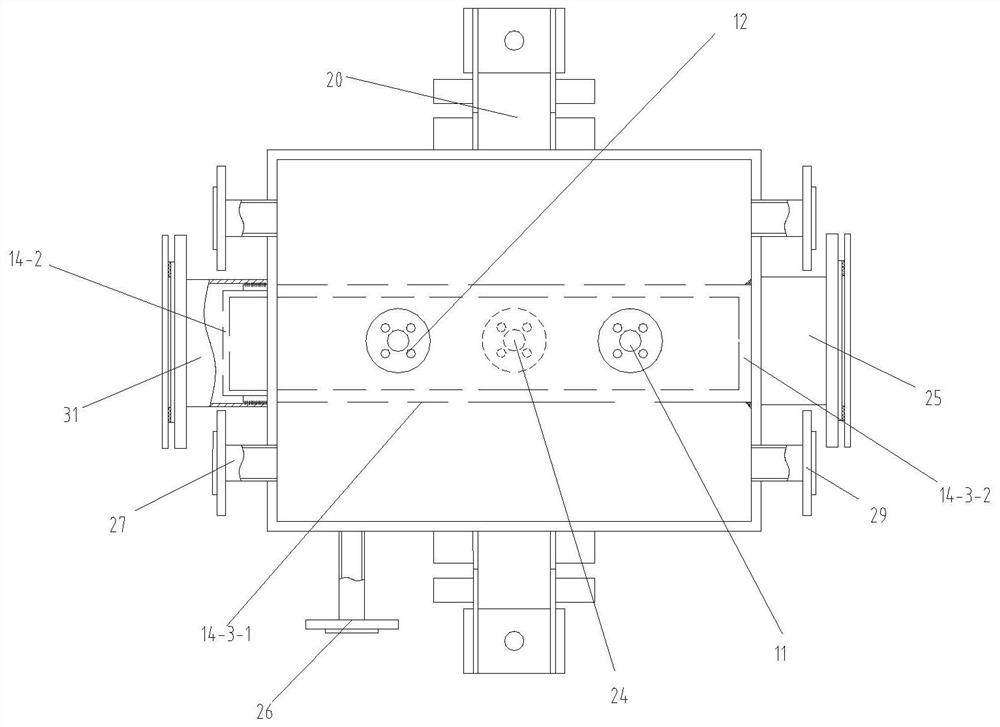

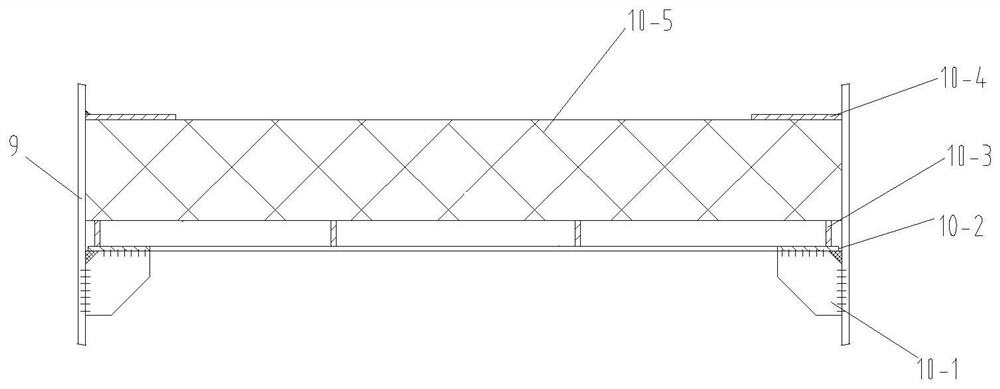

[0110] Such as figure 1 , figure 2 , Figure 8 and Figure 9 Shown is a seawater desalination corrosion test method, the device used in the method includes a test box, a wire mesh demister mechanism 10 and a spray mechanism arranged in the test box, the wire mesh demister mechanism 10 is located at the top of the test box, the wire mesh demister mechanism 10 is higher than the spray mechanism, and the first hanging piece assembly and the second hanging piece assembly are sequentially arranged in the test box from top to bottom. And the third hanging piece assembly, the first hanging piece assembly is located between the wire mesh demister mechanism 10 and the spray mechanism, the third hanging piece assembly is located at the bottom of the test box, the The second hanger assembly is located between the spray mechanism and the third hanger assembly, the spray mechanism is higher than the second hanger assembly and the third hanger assembly, and the first hanger The assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com