Battery assembling device

A technology for battery assembly and battery assembly, which is used in battery assembly machines, secondary battery manufacturing, sustainable manufacturing/processing, etc., can solve problems such as low assembly efficiency, and achieve the effect of improving yield and welding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further illustrate the technical means and effects adopted by the present invention, a detailed description will be given below in conjunction with a preferred embodiment of the present invention and its accompanying drawings.

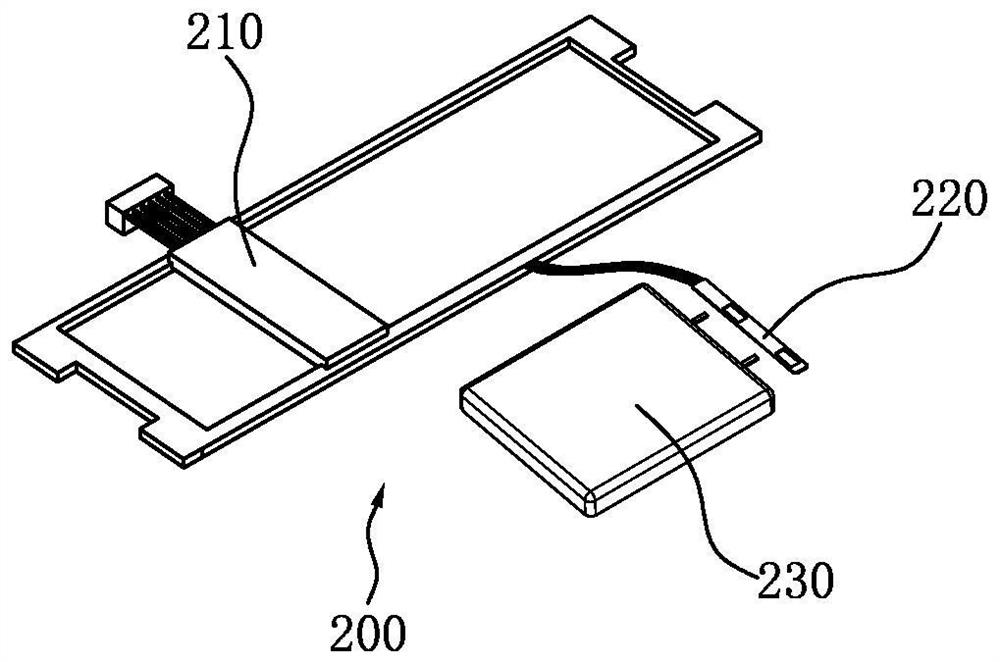

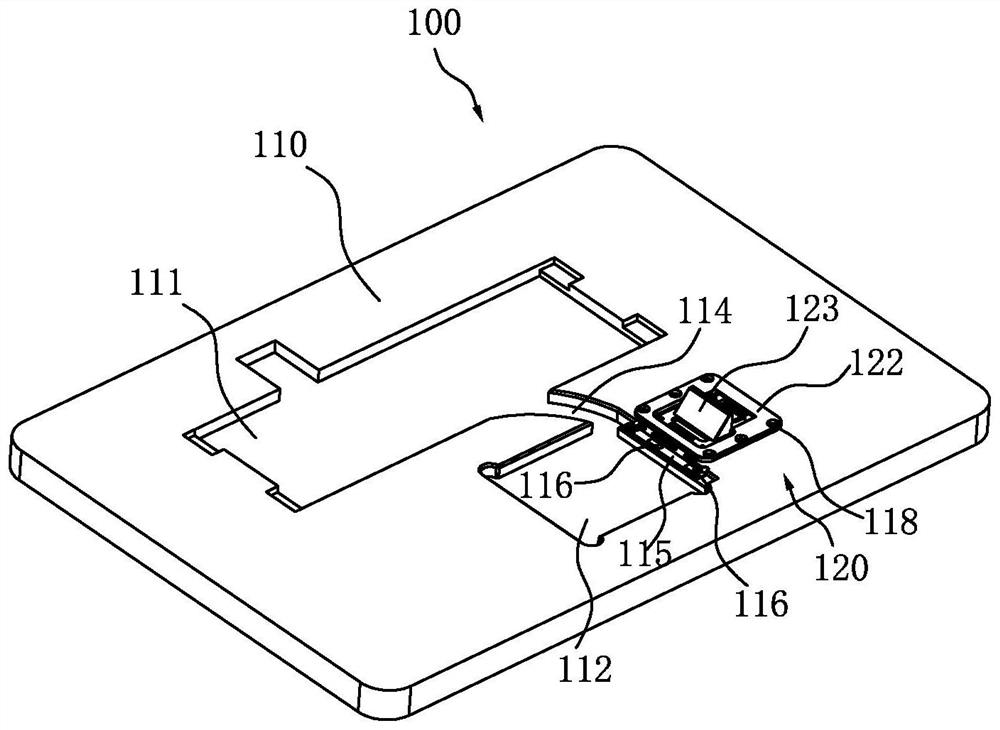

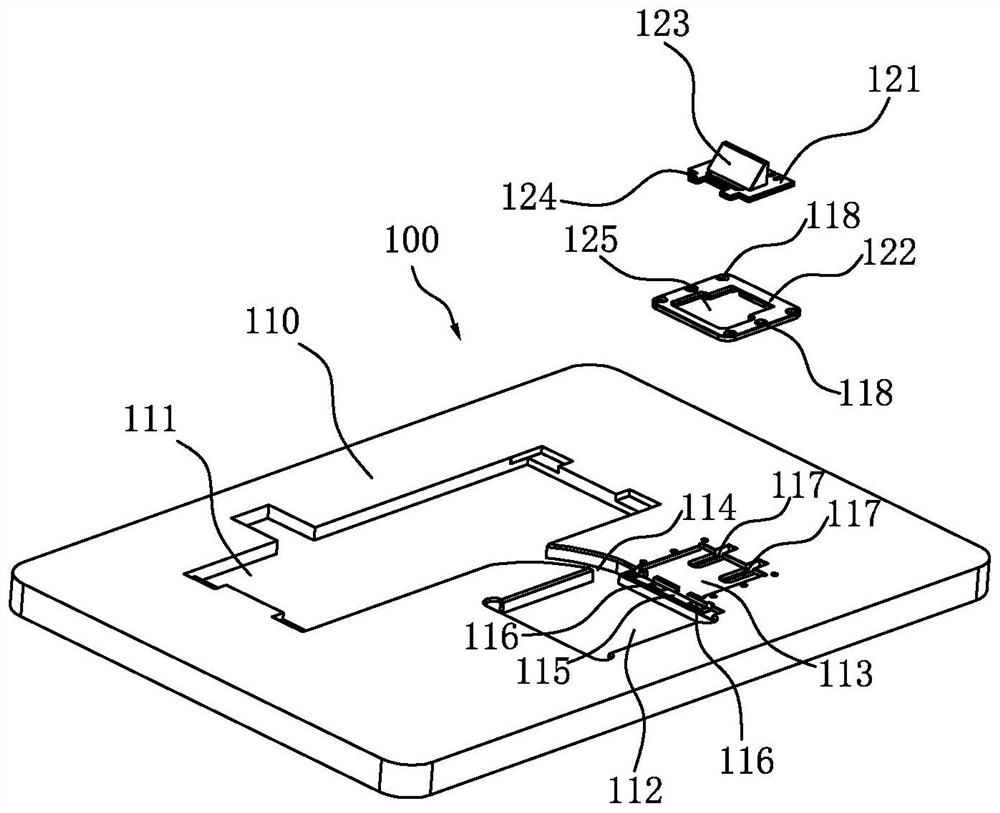

[0024] see Figure 2 to Figure 3 , figure 2 A schematic diagram showing the structure of the battery assembly device of the present invention, image 3 A schematic structural view showing the split state of the battery assembly device of the present invention. In this embodiment, the battery assembly device 100 of the present invention is used to assemble a battery assembly. The battery assembly 200 includes a circuit board 210, a connecting joint 220 and a lithium battery 230. The battery assembly device includes:

[0025] Fixed bottom plate 110, its upper surface is provided with a first groove 111, a second groove 112, a third groove 113 and an arc groove 114, and the arc groove 114 is arranged on the first groove Between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com