Assembly type system for threading in cavity of dry method terrace, and construction method of assembly type system

A flat cavity and prefabricated technology, which is applied to the prefabricated system and its construction field of threading in the dry floor cavity, can solve the problems of wasting manpower and inconvenient operation, so as to improve construction efficiency, facilitate laying, and facilitate single operation. The effect of human operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The embodiment of the present application discloses an assembled system for threading in a cavity of a dry floor.

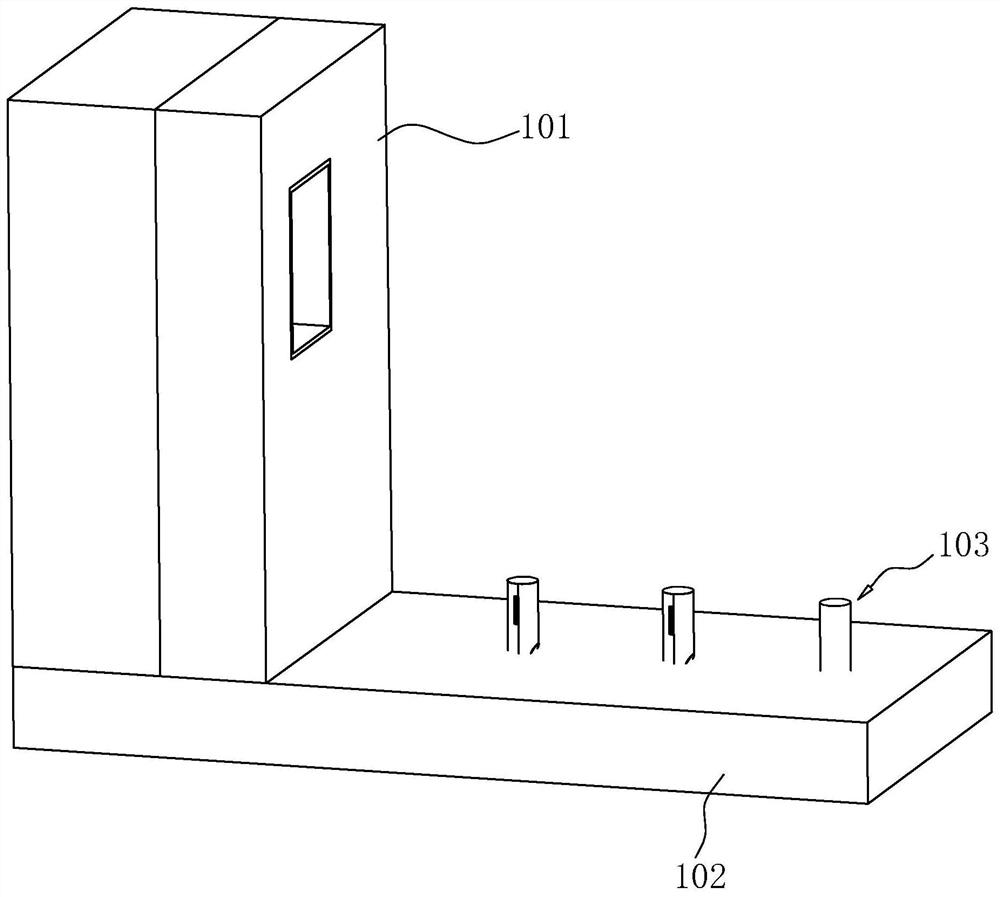

[0049] like figure 1 As shown, an assembled system for threading in a dry floor cavity includes a wall 101, a floor 102, a threading driving device and a threading positioning device.

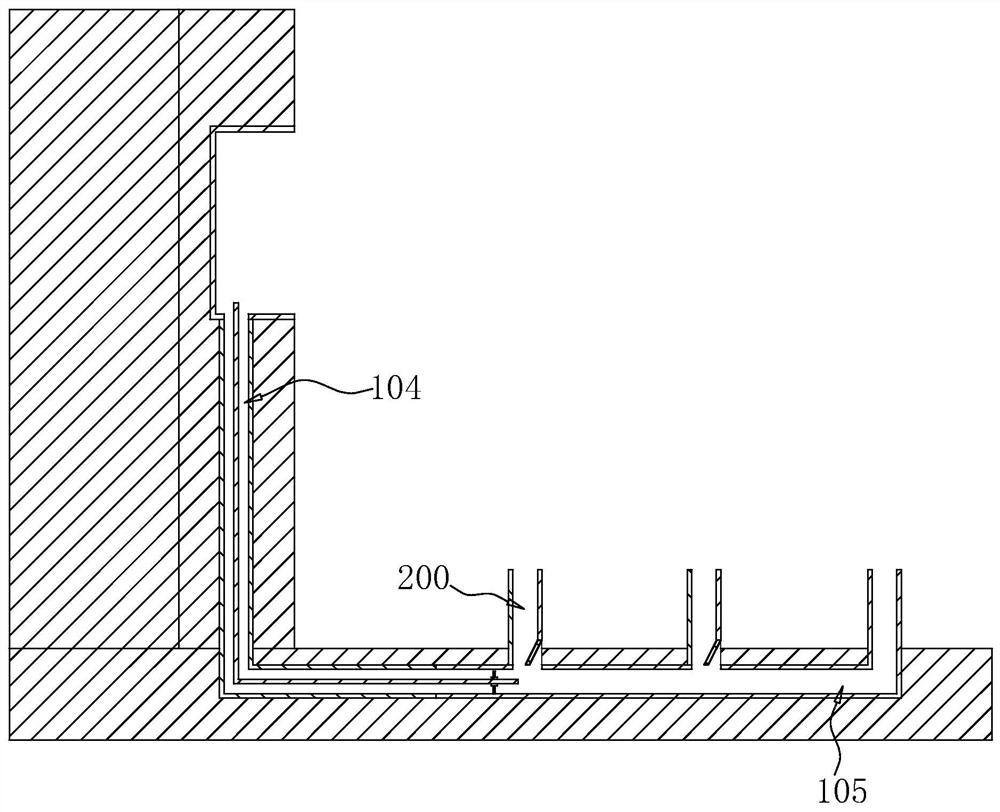

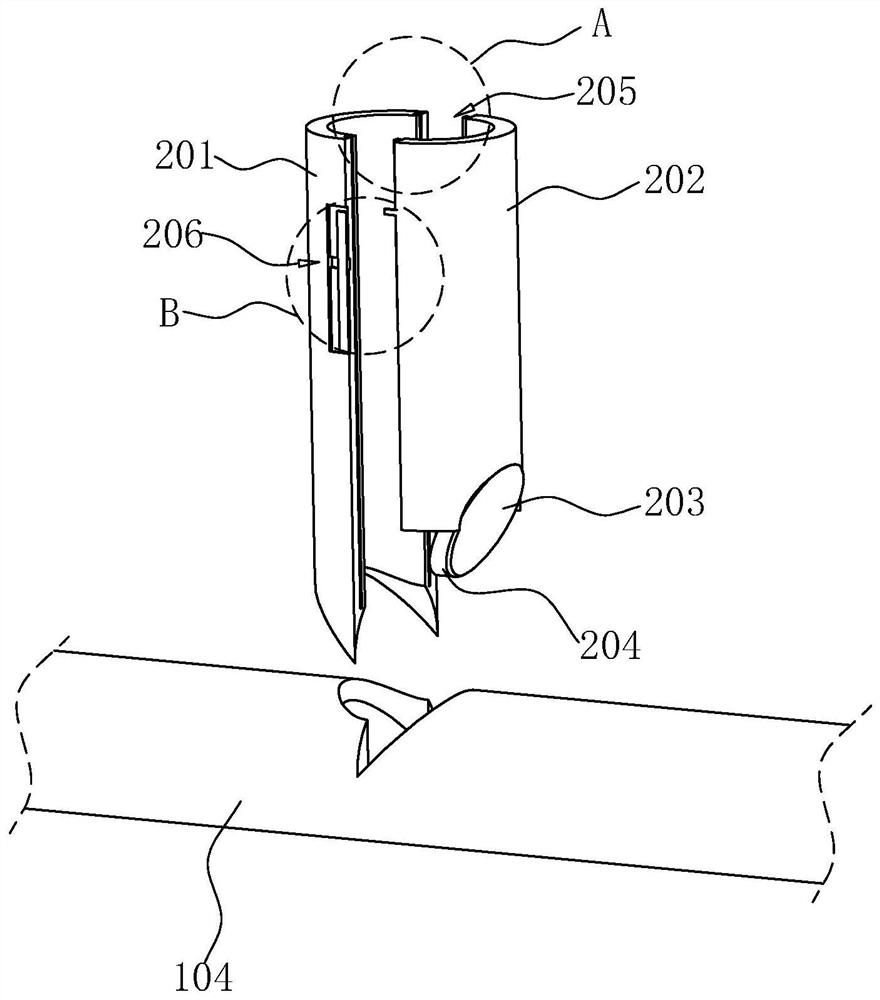

[0050] like figure 2 As shown, the wall 101 and the floor 102 are both constructed by dry method with hollow prefabricated parts, and the prefabricated parts are connected to each other to form a channel in the wall 101 and the floor 102, and the channel is embedded with a pipe for passing wires 103, the pipeline 103 includes a horizontal pipe 104, a vertical pipe 105 and a threading pipe 200; the vertical pipe 105 is buried in the channel formed inside the wall 101, the horizontal pipe 104 is buried in the channel formed inside the floor 102, and the threading pipe 200 is inserted in the floor 102 and passes through the floor 102 to communicate with the horizontal pipe ...

Embodiment 2

[0066] The embodiment of the present application discloses a construction method of a prefabricated system for threading in a cavity of a dry floor.

[0067] A construction method of an assembled system for threading a dry floor cavity, comprising the following steps:

[0068] S1: Drill a hole on the floor and pass through the horizontal pipe 104 for inserting the threading pipe 200, fix the first half pipe 201 on the horizontal pipe 104, so that the threading pipe 200 communicates with the horizontal pipe 104, and the second half pipe 202 can be opposite Slip into the inside of the horizontal tube 104 through the first half tube 201;

[0069] S2: Preparation before threading:

[0070] Fix the infrared emitter 301 and the force receiving component 303 on the head of the electric wire, and fix the infrared receiver 302 in each threading pipe 200;

[0071] S3: Pass the electric wire with infrared emitter 301 and force-receiving component 303 through the vertical pipe 105 in th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap