Rotor, motor, food processor, air supply device and household appliance

A technology for food processors and air supply devices, which is applied in the direction of electromechanical devices, motors, pump devices, etc., can solve problems such as the difficulty in realizing lightweight and miniaturized motors, increasing process complexity and production costs, and increasing rotor thickness, etc., to achieve Realization of weight reduction, miniaturization, and thickness reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

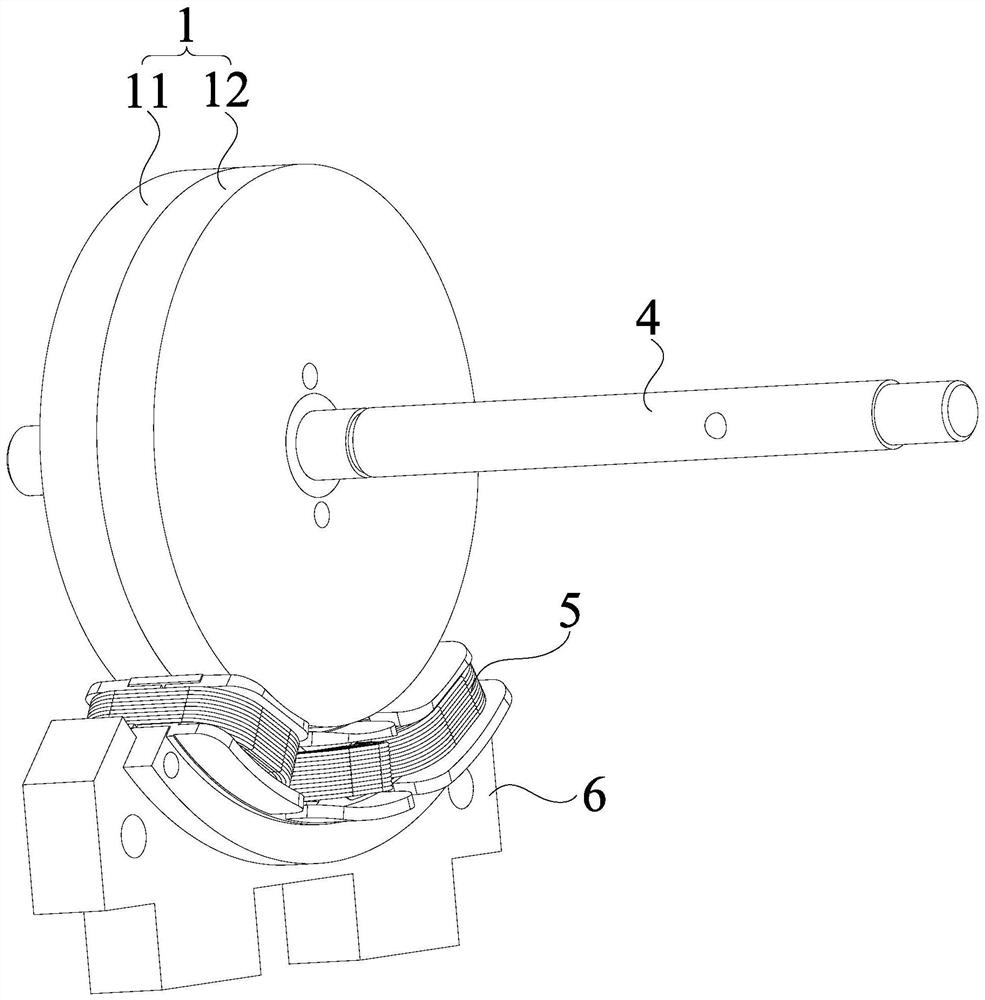

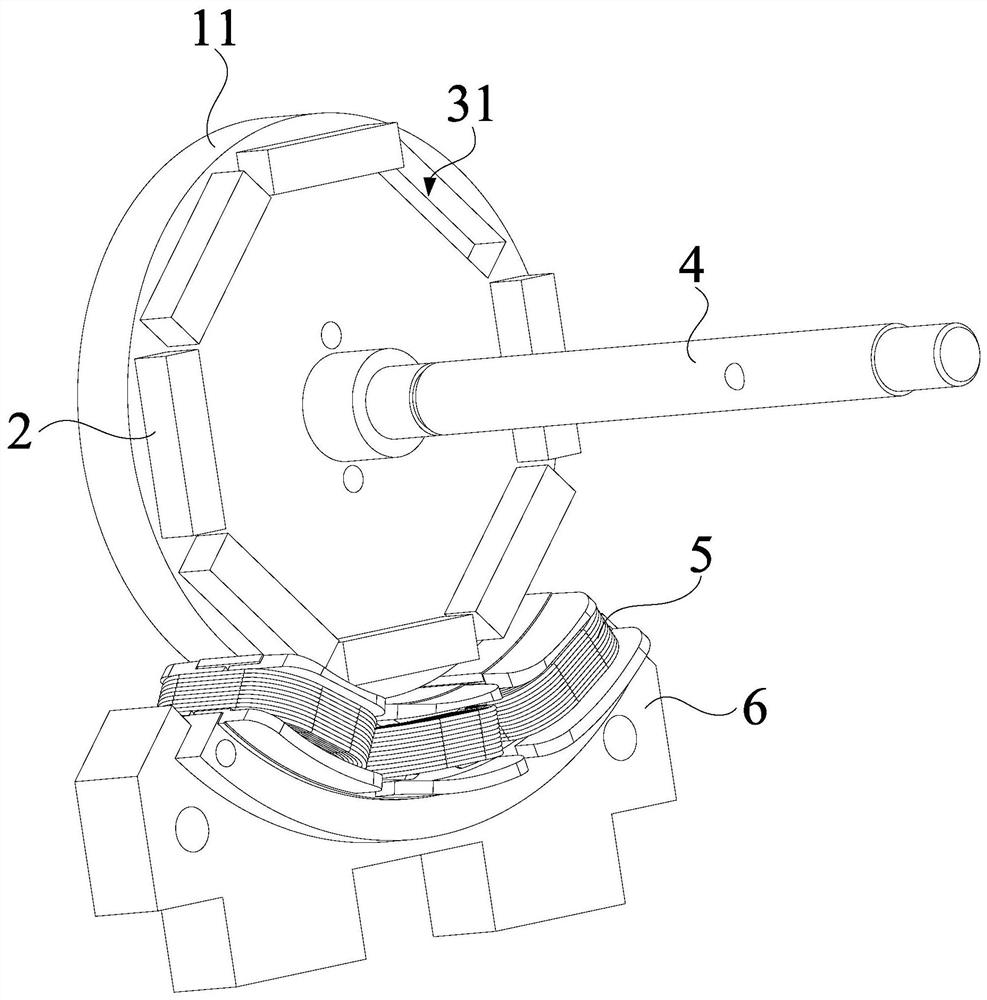

[0098] A rotor 9, combined with Figure 1 to Figure 6 As shown, it includes: a turntable 1 and a magnetic part 2. The turntable 1 includes a first bracket 11 and a second bracket 12. The first bracket 11 and the second bracket 12 form an accommodation space; 2 is set in the installation groove 3.

[0099] In this embodiment, the first bracket 11 and the second bracket 12 are used to replace the rotor core constructed of axially stacked silicon steel sheets in the related art, on the one hand, it is beneficial to reduce the weight of the rotor 9 and reduce the volume of the rotor 9, On the other hand, since the first bracket 11 and the second bracket 12 are not easy to loosen, the structural stability of the rotor 9 is ensured. Moreover, the thickness of the rotor 9 can also be reduced by accommodating the magnetic member 2 in the first bracket 11 and the second bracket 12 , thereby reducing the thickness of the motor, and realizing the weight reduction and miniaturization of ...

Embodiment 2

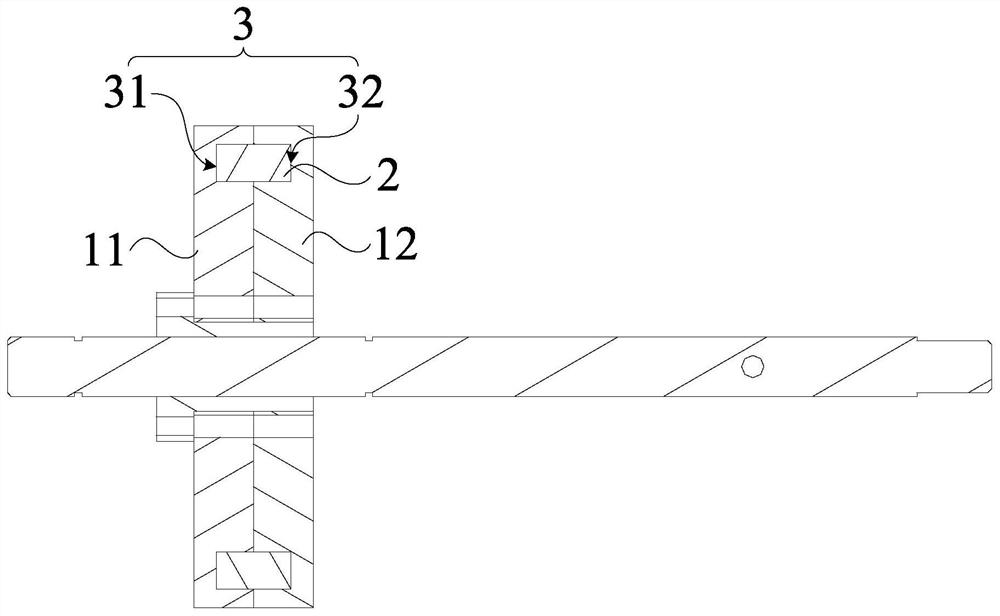

[0104] In any of the above embodiments, the installation groove 3 is provided on the first bracket 11 or the second bracket 12 .

[0105] In a specific embodiment, the first bracket 11 and the second bracket 12 are butted together. The installation slot 3 is disposed on the first bracket 11 , and the notch of the installation slot 3 faces the second bracket 12 .

[0106] In another specific embodiment, the first bracket 11 and the second bracket 12 are butted together. The installation slot 3 is disposed on the second bracket 11 , and the notch of the installation slot 3 faces the first bracket 11 .

[0107] In another specific embodiment, the first bracket 11 is arranged around the outer periphery of the second bracket 12 , and the installation groove 3 is provided on a side of the first bracket 11 facing the second bracket 12 .

[0108] In another specific embodiment, the first bracket 11 surrounds the outer periphery of the second bracket 12 , and the installation groove ...

Embodiment 3

[0110] The difference from the second embodiment is that the installation groove 3 is provided on the first bracket 11 and the second bracket 12 .

[0111] In a specific embodiment, combining Figure 2 to Figure 5 As shown, each installation groove 3 includes a first installation groove 31 and a second installation groove 32 . The first installation slot 31 is provided on the first bracket 11 , and the second installation slot 32 is provided on the second bracket 12 ;

[0112] In another specific embodiment, each installation groove 3 includes a first installation groove 31 and a second installation groove 32, the first installation groove 31 is arranged on the first bracket 11, and the second installation groove 32 is arranged on the second bracket 12 Above: the first installation slots 31 and the second installation slots 32 are alternately distributed, that is, each first installation slot 31 and each second installation slot 32 accommodates part of the magnetic component ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com