Rotor cores, rotor structures, motors and compressors, and electrical appliances having them

A technology of rotor core and rotor structure, which is applied in the field of rotor structure, rotor core, motor and compressor and electrical appliances with it, can solve the problems of permanent magnet synchronous motor noise and vibration, reduce electromagnetic vibration and electromagnetic noise, Improvement of air-gap magnetic field waveform and performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

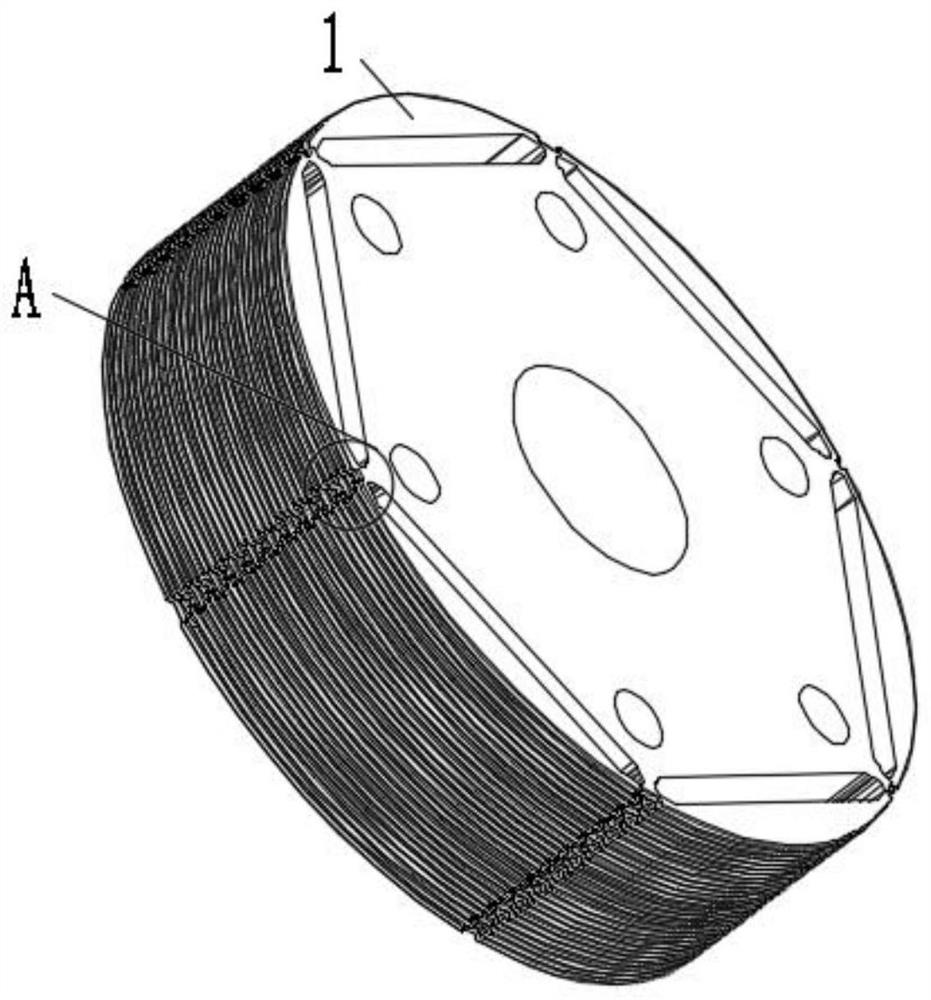

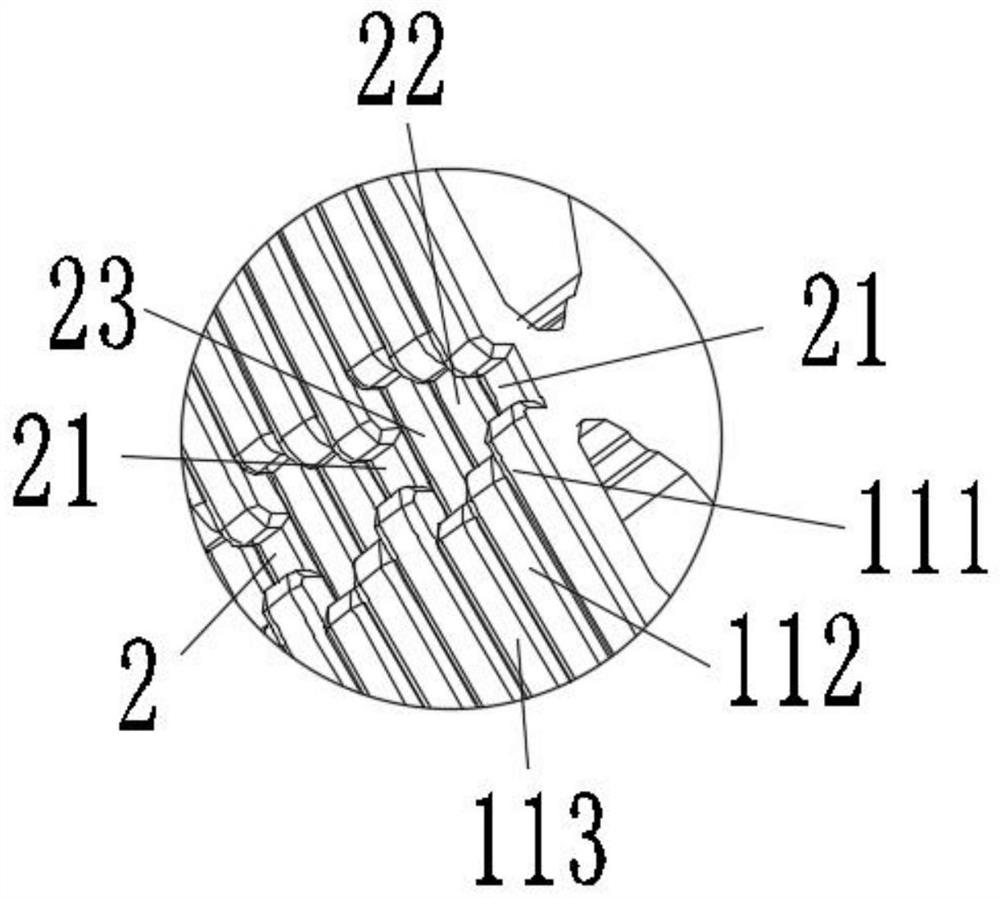

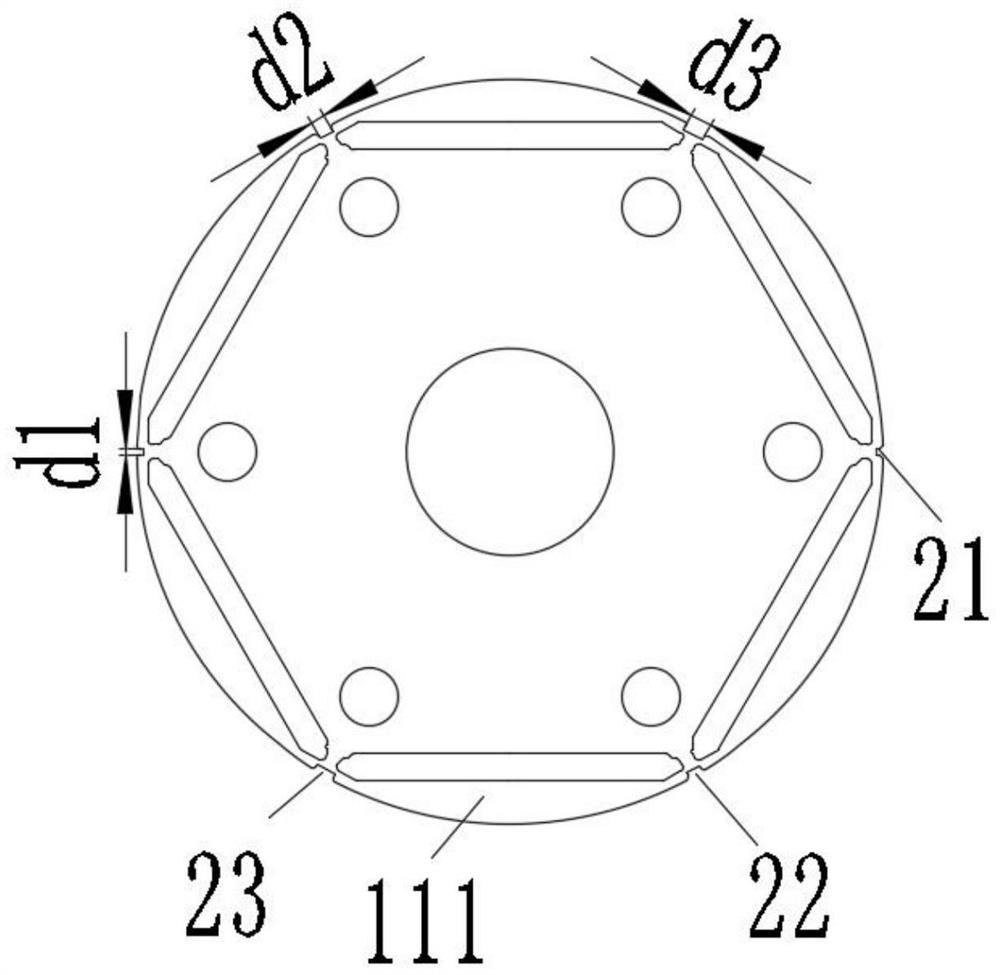

[0032] see in combination figure 1 As shown, according to an embodiment of the present application, a rotor iron core includes: an iron core body 1; a groove group is provided on the outer peripheral wall of the iron core body 1; the groove group includes n grooves 2; In the group, each groove 2 is different in size from any other groove 2; the n grooves 2 are all located in the q-axis direction; where n≧2; in the q-axis direction, the outer peripheral wall of the core body 1 increases At least two grooves 2, and the size of each groove 2 is different. This uneven distribution makes the q-axis air gap length unevenly distributed, so that an uneven air gap structure is formed between the stator and rotor, and the air gap magnetic field of the motor is improved. waveform, weaken the non-uniform air gap caused by the eccentricity of the crankshaft, greatly reduce the torque ripple of the motor, thereby reducing the electromagnetic vibration and electromagnetic noise of the motor,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com