Positive electrode active material for secondary battery and lithium secondary battery comprising same

A technology for positive electrode active materials and lithium secondary batteries, which is applied in the direction of secondary batteries, battery electrodes, active material electrodes, etc., can solve problems such as difficult to uniformly coat/dope the surface or lattice of positive electrode active materials, and achieve Effect of suppressing resistance increase rate and increasing capacity retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

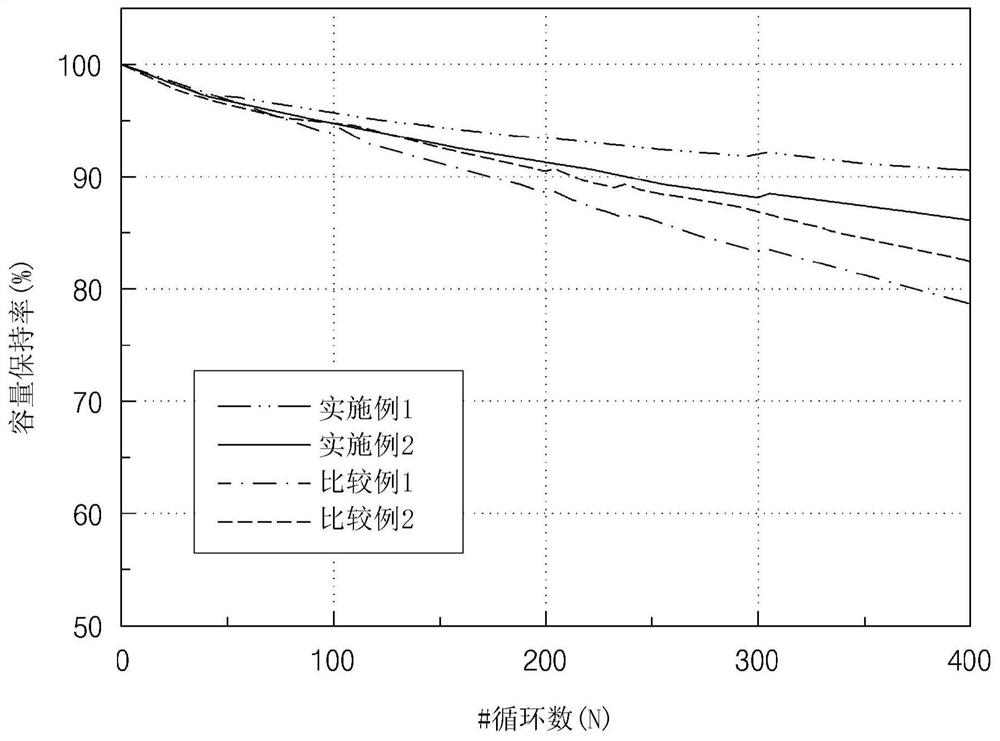

Examples

Embodiment 1

[0083] will Ni 0.69 co 0.13 mn 0.18 (OH) 2 The positive active material precursor and the lithium raw material (LiOH) were added to a Henschel mixer (700 L) so that the final molar ratio of Li / M(Ni,Co,Mn) was 1.05, and then mixed at a center speed of 300 rpm for 20 minutes . Put the mixed powder into an alumina crucible with a size of 330 mm × 330 mm, in oxygen (O 2 ) atmosphere at 500° C. for 10 hours, and then sintered at 730° C. for 30 hours to prepare a positive electrode active material.

Embodiment 2

[0085] A positive electrode active material was prepared in the same manner as in Example 1, except that the mixed powder was kept at 500° C. for 10 hours and then sintered at 750° C. for 20 hours.

experiment example 1

[0090] [Experimental Example 1: Measurement of crystallite size and strain]

[0091] The crystallite sizes of the cathode active materials prepared in Examples 1 and 2 and Comparative Examples 1 and 2 were measured. crystallite size FWHM is the crystallite size calculated from XRD data using the full width at half maximum (FWHM) method, the crystallite size IB is the crystallite size calculated from XRD data using the integrated width (IB) method.

[0092] [Table 1]

[0093] crystallite size FWHM (nm)

[0094] Referring to Table 1, for Examples 1 and 2, crystallite size FWHM Meet 80nm to 150nm, Δ size (|crystallite size IB – crystallite size FWHM ) (that is, strain) satisfies 20 or less, while Comparative Examples 1 and 2 do not satisfy Relational Expression 1 and / or Relational Expression 2, and a deviation occurs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com