Multi grinding wheel for OLED substrate and method for grinding OLED substrate using the multi grinding wheel

A light-emitting diode, multi-functional technology, applied in grinding/polishing equipment, machine tools suitable for grinding the edge of workpieces, grinding devices, etc., can solve the problems of organic light-emitting diodes that are defective and cannot be easily removed, and achieve improved grinding quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

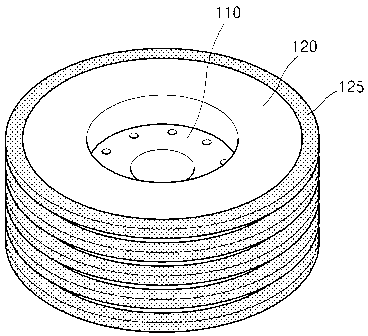

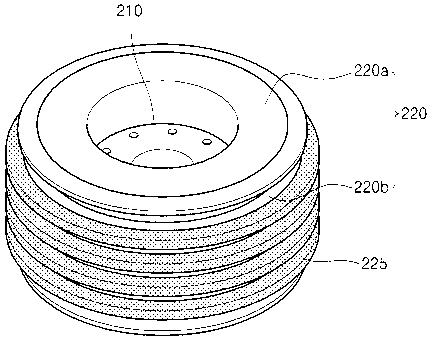

[0027] The embodiments described in detail below with reference to the accompanying drawings will make the advantages and features of the present invention and methods for achieving the advantages and features more apparent. However, the present invention is not limited to the embodiments disclosed below, and can be implemented in various ways. A skilled person fully understands the scope of the present invention, and the present invention is defined according to the scope of the claims. Throughout the specification, the same reference numerals denote the same structural elements.

[0028] The multifunctional grinding wheel for organic light emitting diode substrates of the present invention and the grinding method of organic light emitting diode substrates using the multifunctional grinding wheel will be described in detail below with reference to the accompanying drawings.

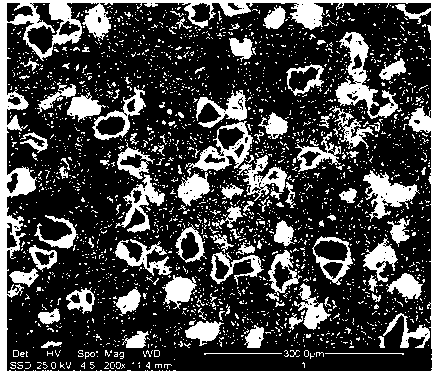

[0029] The multifunctional grinding wheel of the present invention is used as a grinding wheel for g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com