Electric transplanter

A transplanting machine, electric technology, applied in the field of agricultural cultivation, can solve the problems that the position of seedlings cannot be automatically excreted, and the transplanting machine does not have universal applicability, so as to achieve the effect of shortening the planting time, easy operation, and easy positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

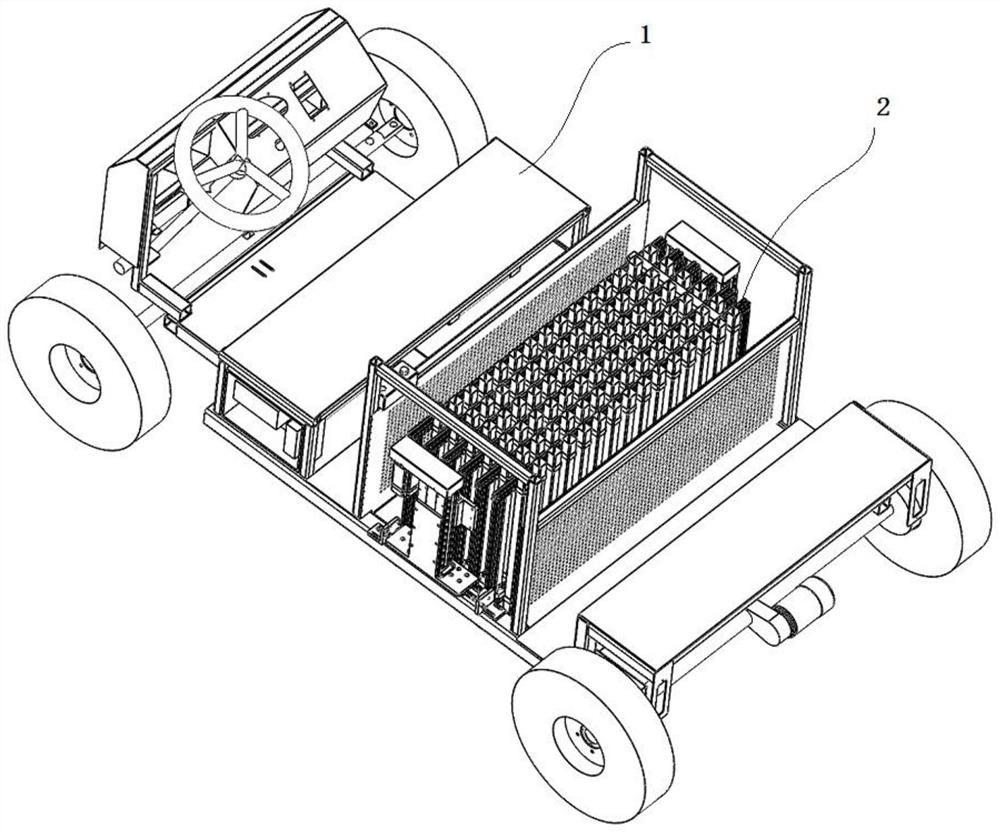

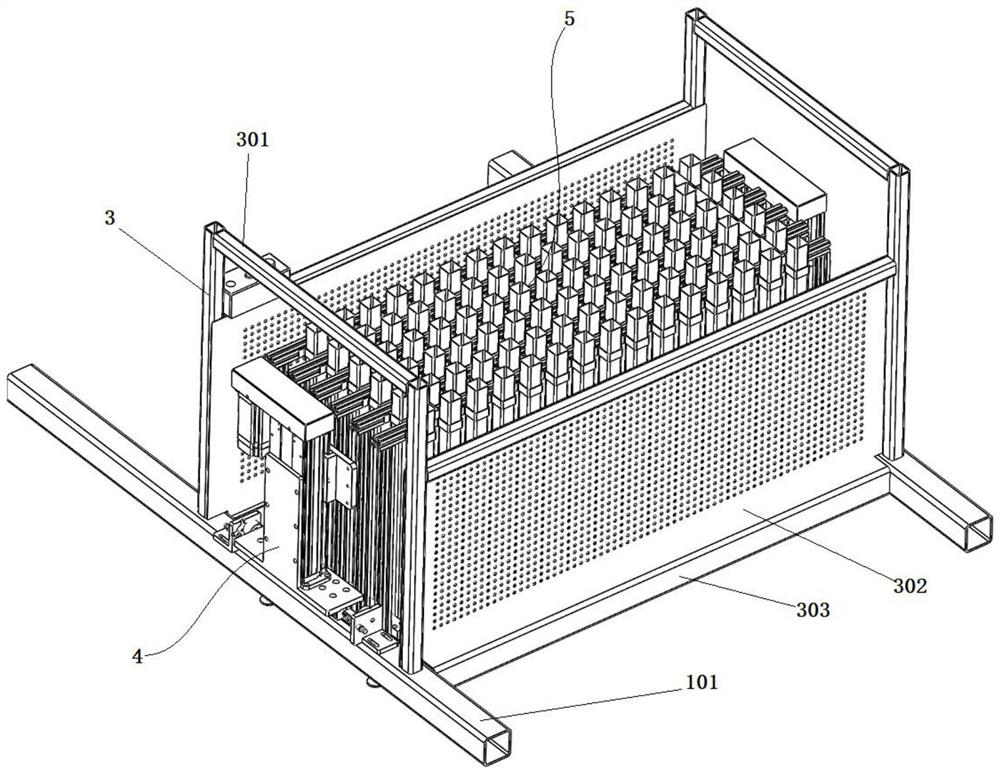

[0035]Such asFigure 1-6As shown, an electric transplanter includes a walking assembly 1 on which a planting assembly 2 is fixedly installed; the walking mechanism 1 is an electric trolley body, which includes a walking wheel, a control panel, and a steering wheel. Related parts required by the assembly are not the core of this application, so I won’t go into details here;

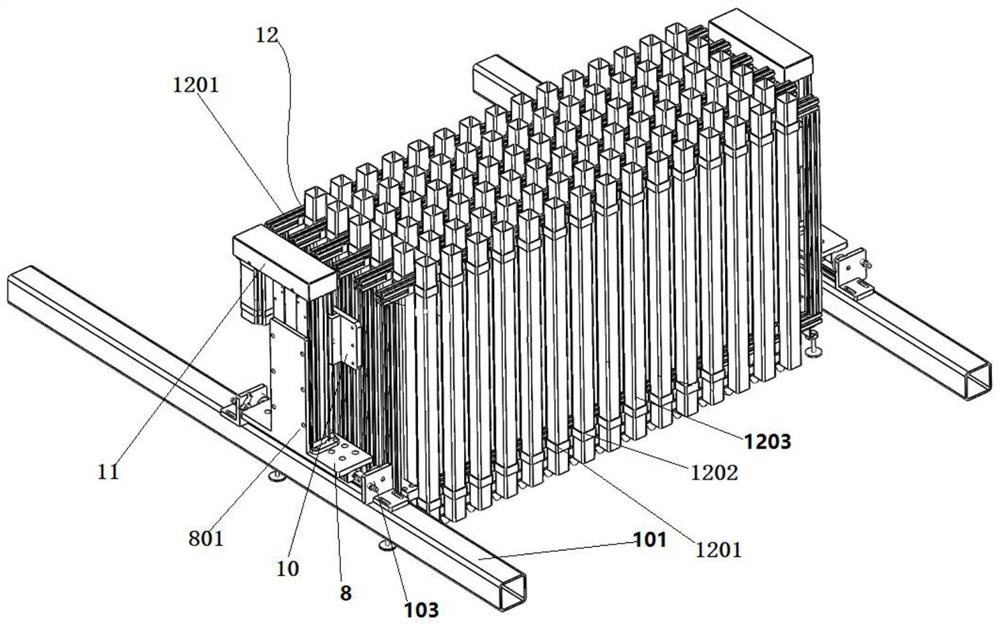

[0036]Wherein, the planting assembly 2 includes four uprights 3 fixed on the frame 101 of the traveling mechanism 1, and the upper end of the upright 3 is fixed with a reinforcing rod 301 along the direction of the frame 101, and one of the uprights 3 perpendicular to the reinforcing rod 301 Two front and rear protective cover plates 302 are fixed in between, and a number of through holes are opened on the protective cover plate 302; the upper and lower ends of the protective cover plate 302 are fixedly connected with a reinforcing plate 303;

[0037]The frame 101 between the protective cover plates 302 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com