A kind of lipophilic graphene nano sheet and preparation method thereof

A technology of graphene nanosheets and lipophilicity, which is applied in the direction of graphene, nanocarbon, chemical instruments and methods, etc., can solve the problems of low dispersion stability, achieve low cost, improve hydrophobic and lipophilic properties, and improve dispersion stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention provides a kind of preparation method of lipophilic graphene nano sheet, comprising:

[0039] Step S1, preparing thermally reduced graphene;

[0040] Step S2, taking the thermally reduced graphene and peroxide obtained in step S1 respectively according to a mass ratio of 1:9 to 15, stirring and mixing to obtain a solid mixture;

[0041] Step S3, placing the solid mixture obtained in step S2 in a sealed container filled with an inert gas, reacting at 50-150° C. for 2-5 hours, and cooling to obtain a reacted solid;

[0042] In step S4, the reacted solid obtained in step S3 is taken out, washed, filtered, dried, and ground; the target graphene is obtained.

[0043] Optionally, the particle size of the target graphene is 50-500 mesh. For example but not limited to, the particle size of the target graphene is 100 mesh.

[0044] Optionally, in step S2, the peroxide is lauroyl peroxide, benzoyl tert-butyl peroxide, methyl ethyl ketone peroxide, tert-butyl acet...

Embodiment 9

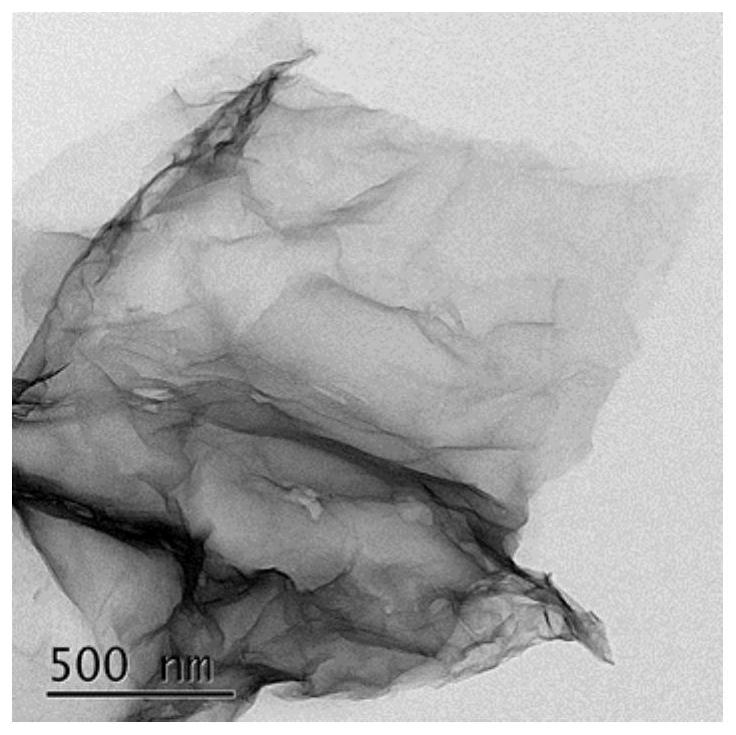

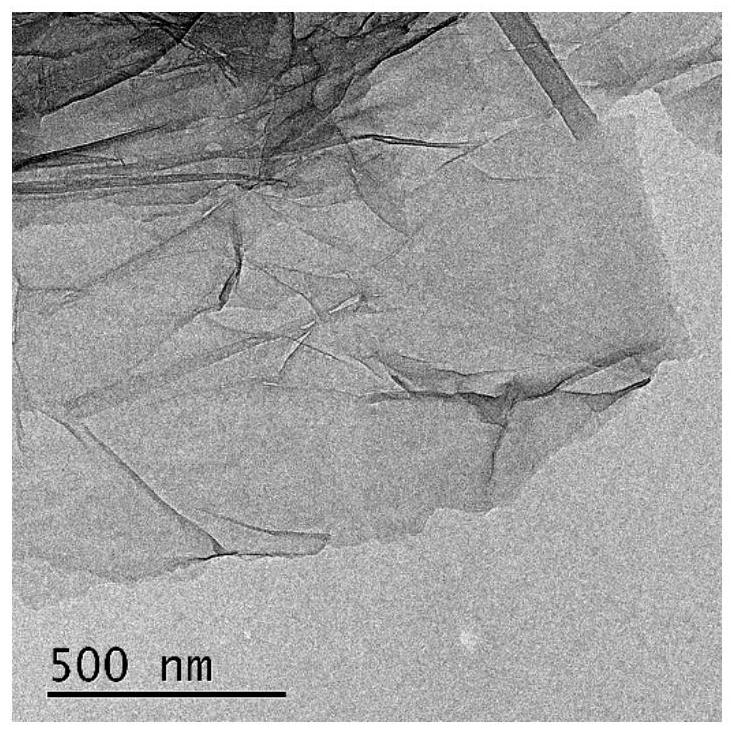

[0072] Embodiment 9 is to the transmission electron microscope (HRTEM) analysis of prepared TRGO and X-TRGO (it should be noted that, the performance detection of this experiment, what choose is that the mass ratio is 1:12 TRGO and benzoyl peroxide preparation The obtained X-TRGO. At the same time, it should be noted that the following examples are all X-TRGO prepared under this condition, and will not be repeated one by one hereafter)

[0073] 1. Experimental operation:

[0074] Select the TRGO prepared by 1.1 in Example Group 1 and the X-TRGO prepared by TRGO and benzoyl peroxide with a mass ratio of 1:12 in 1.2, carry out transmission electron microscope analysis, and obtain the following figure 1 and figure 2 The transmission electron microscope image is shown.

[0075] 2. Result analysis: by figure 1 and figure 2 It can be seen that the TEM morphology of TRGO (such as figure 1 shown), the lamellar structure is relatively smooth, with a small amount of wrinkles, and...

Embodiment 10

[0076] Example 10 Dispersion experiment of X-TRGO in organic solvent (in this experiment, X-TRGO prepared from TRGO with a mass ratio of 1:12 and benzoyl peroxide was selected))

[0077] 1. Graphene hydrophobic performance test experiment in water

[0078] 1.1. Experimental operation:

[0079] The films of GO (graphene), TRGO (thermally reduced graphene) and TRGO (organized modified graphene) were respectively selected to test the contact angle with water droplets, and the following results were obtained: Figure 3 to Figure 5 The test result graph shown.

[0080] 1.2. Result analysis: by Figure 3 to Figure 5 It can be seen that GO (graphene), TRGO (thermally reduced graphene) and TRGO (organized modified graphene) all exhibit hydrophobicity. Moreover, as the functional groups of graphene are optimized and modified, its hydrophobicity becomes more significant. Specifically, the hydrophobic properties of TRGO are superior to those of TRGO and significantly better than thos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com