Municipal sewage well wall prefabricating and assembling process and concrete well wall component

A municipal sewage, prefabricated and assembled technology, which is applied in the direction of water supply devices, drainage structures, waterway systems, etc., can solve the problems of long construction period and high labor cost, and achieve the effect of simple construction, good integrity and reduced personnel input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

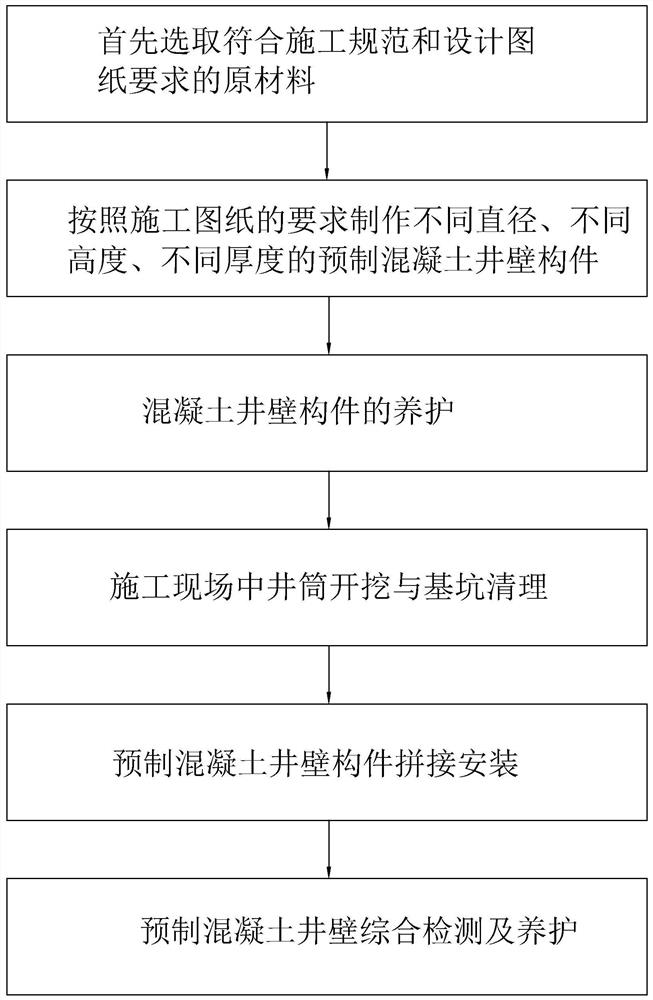

[0043] Embodiment: a prefabricated assembly process of municipal sewage well wall and concrete well wall components, such as figure 1 shown, including the following steps:

[0044] S1: First, select raw materials that meet the requirements of construction specifications and design drawings: sand and gravel, cement, steel bars, and waterstops.

[0045] The selection of sand and gravel should first be determined according to the actual distribution of material sources near the construction site. When there are natural sand and gravel with qualified quality, reserves that meet the needs of the project, and convenient mining and transportation near the construction site, natural sand and gravel should be given priority.

[0046] Natural sand and gravel materials include sand gravel and natural pebbles. After the natural sand and gravel materials are prepared, the natural sand and gravel materials need to be further pulverized with a pulverizer, and the pulverized natural sand and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Carrying capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com