Optical fiber ribbon

A technology of optical fiber ribbon and optical fiber, applied in the direction of light guides, optics, optical components, etc., can solve problems such as inapplicability, and achieve the effect of preventing glue breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

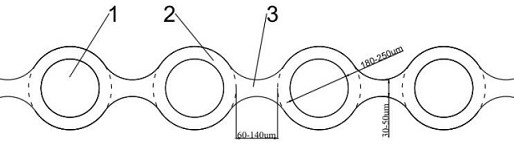

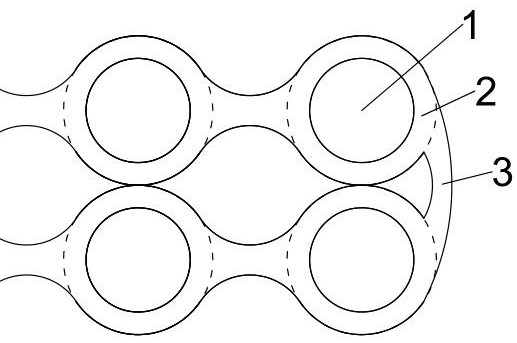

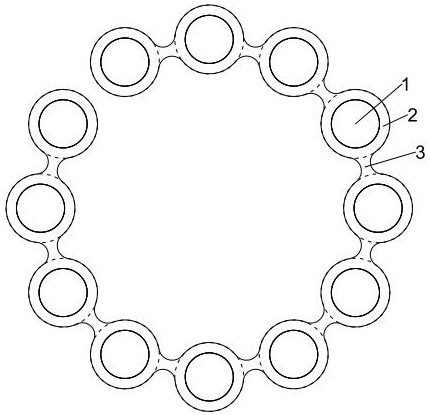

[0022] Such as figure 1 As shown, the optical fiber ribbon includes several optical fibers 1 and a cladding layer 2 covering the optical fibers. The optical fibers 1 pass through the mold cavity of a mold injected with resin to form the cladding layer 2 outside the optical fibers 1 .

[0023] The optical fiber ribbon of this embodiment also includes a connecting portion 3. In this embodiment, twelve optical fibers are taken as an example. The twelve optical fibers 1 are distributed along the linear direction with intervals, and each optical fiber 1 is covered by a coating layer 2 with uniform thickness. , the cladding layers 2 of adjacent optical fibers 1 are connected by the connecting part 3, so that both sides of the optical fiber ribbon along the length direction have a corrugated structure, and the thickness of the connecting part 3 is 1 / 3 to 1 / 2 of the diameter of the cladding layer 2, and Both the connecting part 3 and the cladding layer 2 are made of resin with a Young...

Embodiment 2

[0026] Such as Figure 4-6 As shown, this embodiment is a mold for producing optical fiber ribbons. The mold includes an inlet mold 4, a sizing mold 5 and an outlet mold 6 that fit together. The inlet mold 4, the sizing mold 5 and the outlet mold 6 are respectively provided with a number of connected entrance fiber holes 41 and sizing optical fibers. The hole 51 and the exit fiber hole 61 , this embodiment takes twelve entry fiber holes 41 , sizing fiber holes 51 and exit fiber holes 61 as an example.

[0027] The entrance fiber hole 41, the sizing fiber hole 51 and the exit fiber hole 61 are equally spaced, and the sizing fiber hole 51 aperture is smaller than the entrance fiber hole 41 and the exit fiber hole 61 aperture, which can effectively prevent two adjacent optical fibers 1 from When covering the rubber, the glue is broken at 3 places of the connecting part. The diameter of the entrance fiber hole 41 is 1.03-1.06 times that of the fixed-size fiber hole 51 , and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com