Control system and control method of energy-saving glazing line

A control method and control system technology, applied in the field of control system of energy-saving glazing line, can solve problems such as waste of electric energy, achieve the effect of eliminating no-load operation and reducing power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

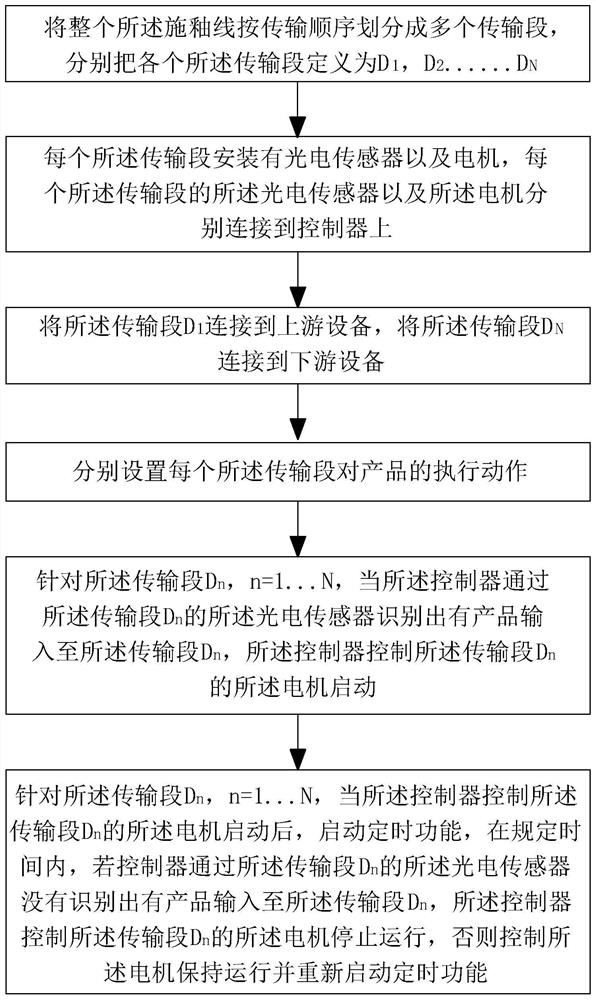

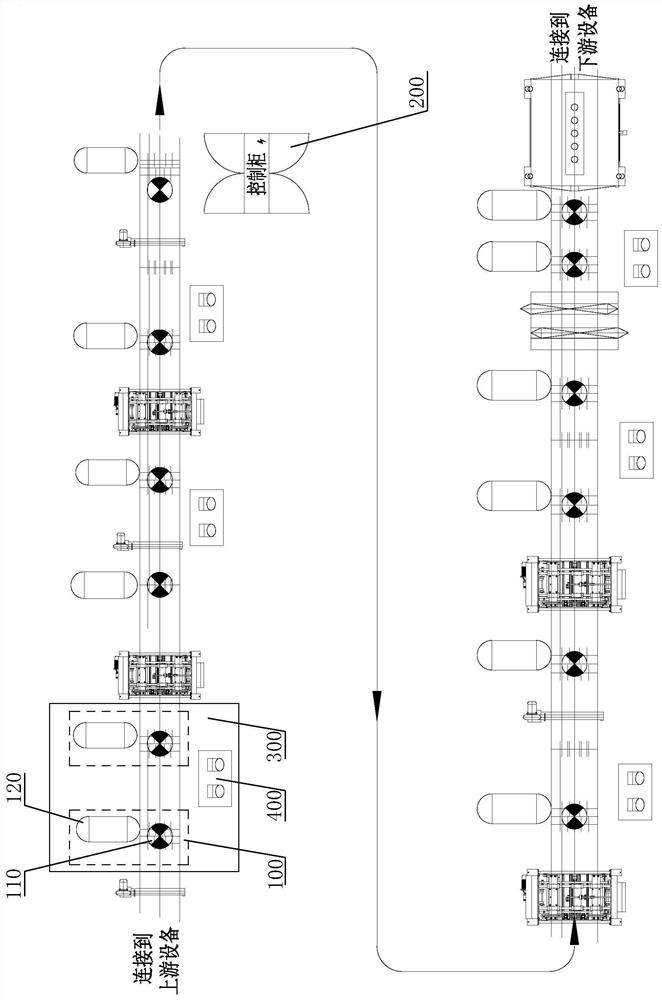

[0026] refer to figure 1 and figure 2 , the present application discloses a method for controlling an energy-saving glazing line, and its first embodiment includes the following steps:

[0027] Step 100, dividing the entire glazing line into multiple transmission sections according to the transmission sequence, and defining each transmission section as D 1 ,D 2 ......D N , each of the transmission sections is equipped with a photoelectric sensor and a motor, and the photoelectric sensor and the motor of each of the transmission sections are respectively connected to the controller;

[0028] Step 200, the transmission segment D 1 connected to an upstream device, the transmission segment D N Connect to downstream equipment;

[0029] Step 300, respectively setting the execution action of each of the transmission segments on the product;

[0030] Step 400, for the transmission segment D n , n=1, 2...N, when the controller passes the transmission segment D n The photoelec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com