Guide rail type degumming machine

A rail-type, melter technology, applied in conveyor objects, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of long cleaning process cycle, large space occupation, and high cleaning cost, and shorten the process cycle and investment. Small, the effect of reducing the process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

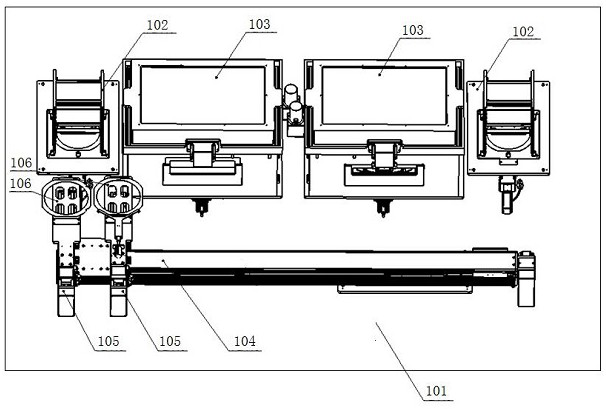

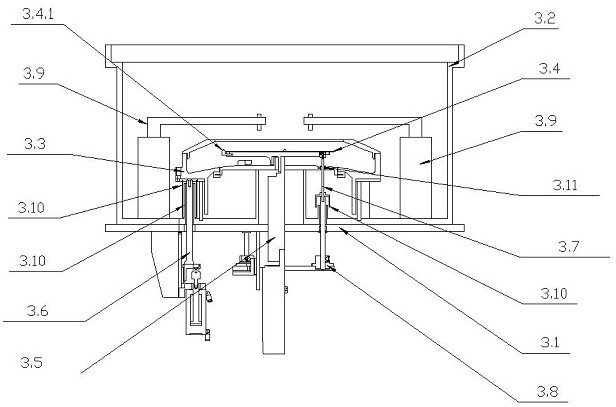

[0026] see Figure 1~5 , a kind of rail-type deglue machine that the present invention relates to includes a film cassette unit 102 and a degumming unit 103 installed on one side of the machine table 101. The two film cassette units 102 are respectively located on both sides of the degumming unit 103. The machine A slide module 105 is slidably arranged on the slide rail 104 on the other side of the table 101, and an adsorption mechanism 106 is installed on the slide module 105;

[0027] When in use, the adsorption mechanism 106 grabs the substrate from the cassette unit 102 on one side, and then passes through multiple degumming units 103 for degumming and cleaning successively under the drive of the sliding module 105, and puts it into the other side after the degumming and cleaning is completed. In the film box unit 102 of;

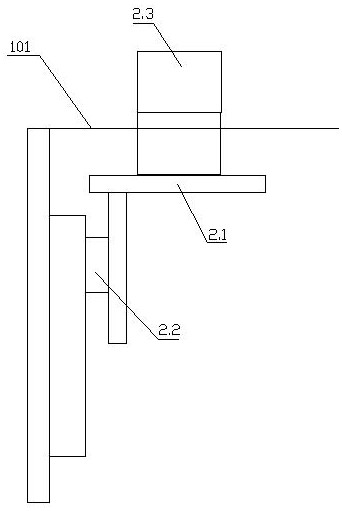

[0028] join figure 2 , further, the cassette unit 102 includes a lifting platform 2.1 installed on the lifting module 2.2, and the lifting platform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com