A kind of preparation method of lead-acid battery positive electrode paste and positive plate

A lead-acid battery and positive lead paste technology, which is applied to lead-acid battery electrodes, battery electrodes, chemical instruments and methods, etc., can solve the problems that the content of α-PbO2 in the positive plate cannot be effectively increased, and the expected effect is not achieved. , to achieve the effect of high static charge acceptance, deep high temperature life and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The prepared barium-doped carbon nitride is added to the positive lead paste of the battery as an additive material, and the preparation method of the positive plate includes the following steps:

[0041] ①Lead powder, short fiber, barium-doped carbon nitride are stirred and mixed evenly according to the mass ratio of 100:(0.05-0.5):(0.1-1.0);

[0042] ②Add 10-15% water of the mixture mass to the mixture obtained in step ①, fully stir for 1-30min, then add 6-10% of the mixture mass of dilute sulfuric acid aqueous solution, fully stir for 1-30min to obtain lead paste, positive lead paste The density is 3.5-4.5g / cm 3 ;

[0043] ③Scratch the lead paste evenly on the grid, the thickness of the lead paste is 0.5-10mm, cure at 20-80°C for 1-50h, the relative humidity during the curing process is 90-100%, and then dry at 50-100°C for 0.5 -24h, the relative humidity in the drying process is 0-20%, and the positive plate is obtained.

Embodiment 1

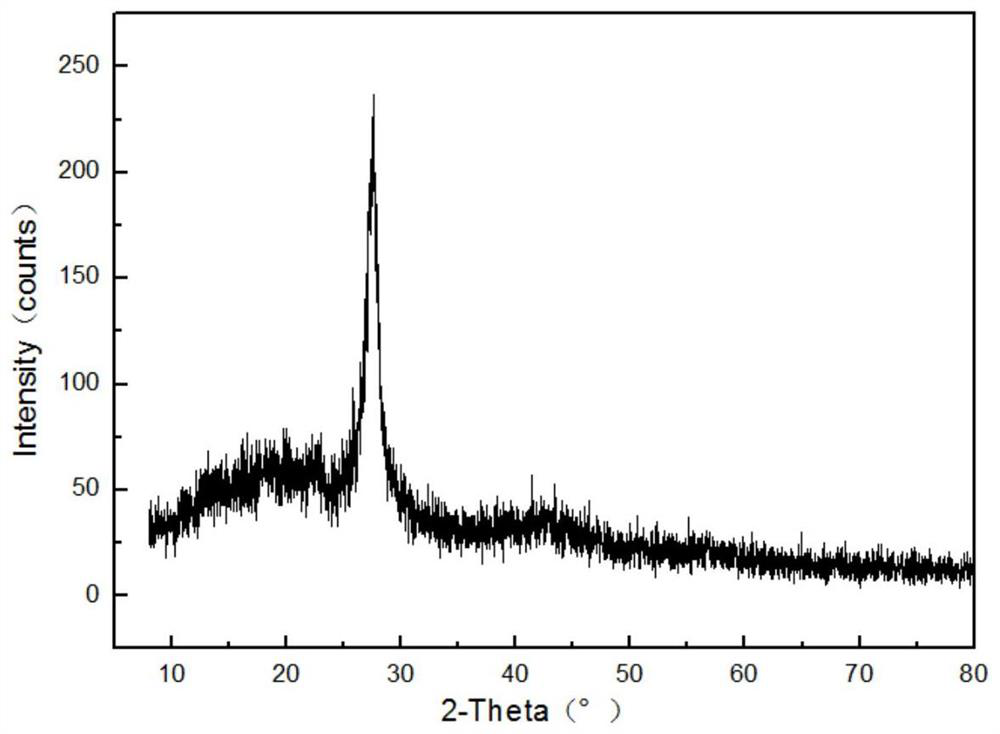

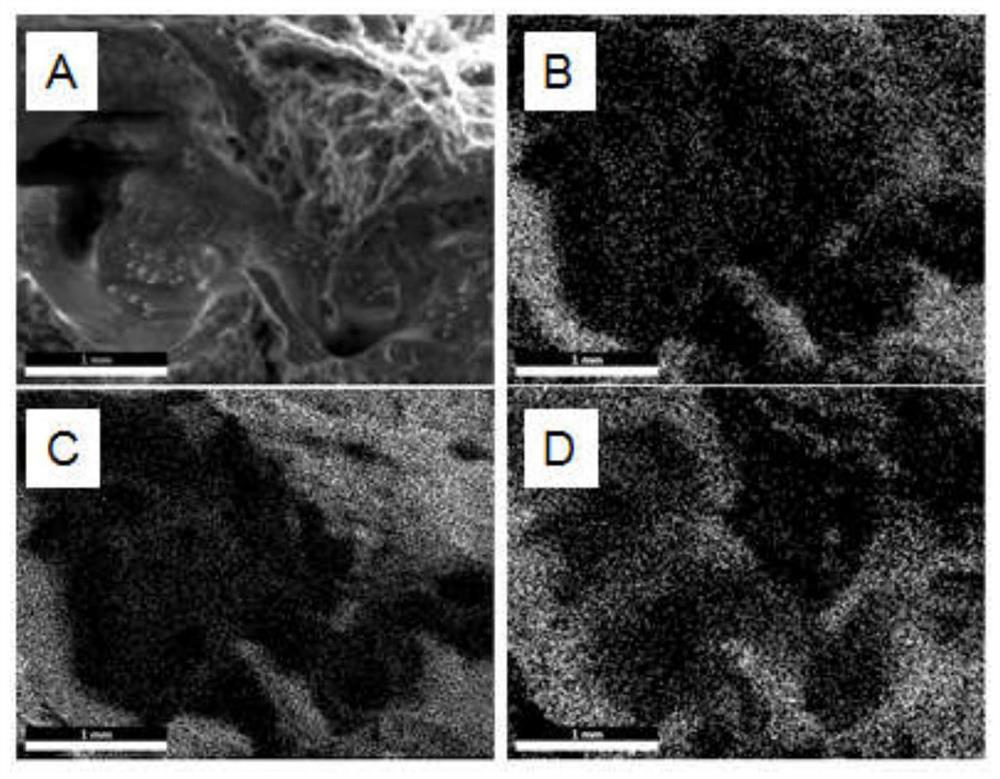

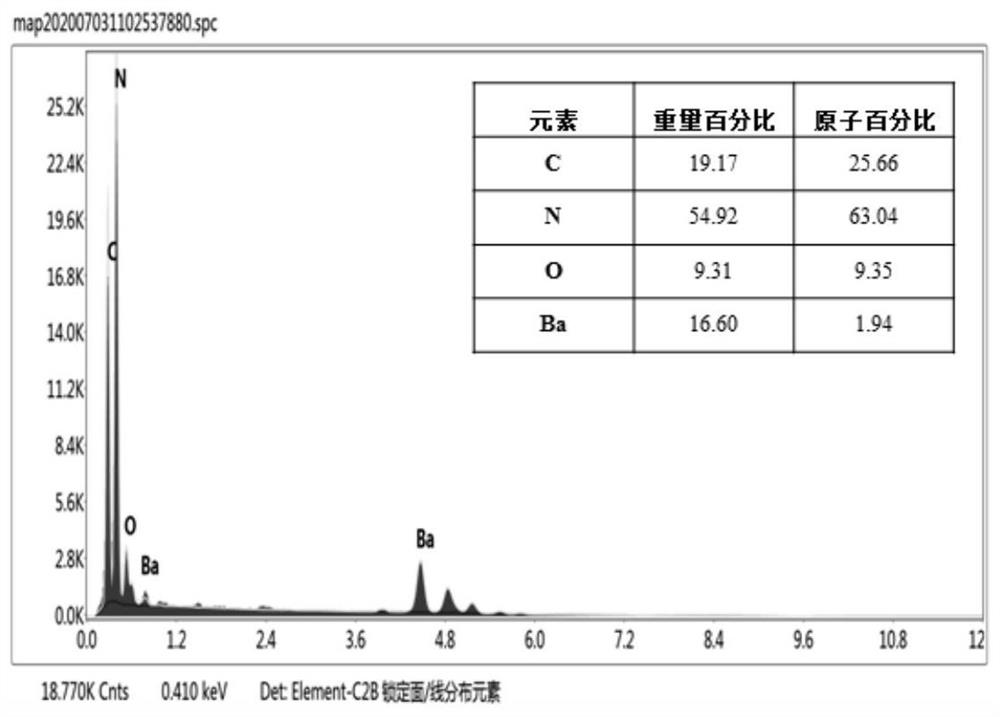

[0045] Preparation of barium-doped carbon nitride: weigh 3.0g of Ba(OH) 2 , was added to 100g of pure water, stirred thoroughly until completely dissolved, and Ba(OH) was obtained 2 solution. Take by weighing 10.0g melamine, add to Ba(OH) 2 In the solution, a barium-doped melamine precursor turbid solution is obtained. Stir the turbid solution for 10min and let it stand for 2h. drying the turbid solution of the barium-doped melamine precursor at 100° C. for 24 hours to obtain the barium-doped melamine precursor powder. The obtained barium-doped melamine precursor powder was heated to 550° C., and kept roasting for 2.0 h to obtain novel barium-doped carbon nitride particles. During calcination, the precursor powder was placed in a crucible with a lid under CO 2 In a protective atmosphere. Grinding the obtained novel barium-doped carbon nitride particles into a powder with an average particle diameter of less than 5 μm to obtain a novel barium-doped carbon nitride material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com