Injection mold for shell body of displayer support, and forming process thereof

A technology of display bracket and injection mold, applied in the direction of coating, can solve the problems of reducing the molding efficiency of the display bracket, and the finished product and the mold are not easy to debond, etc., and achieve the effect of reducing local oxidation and improving separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

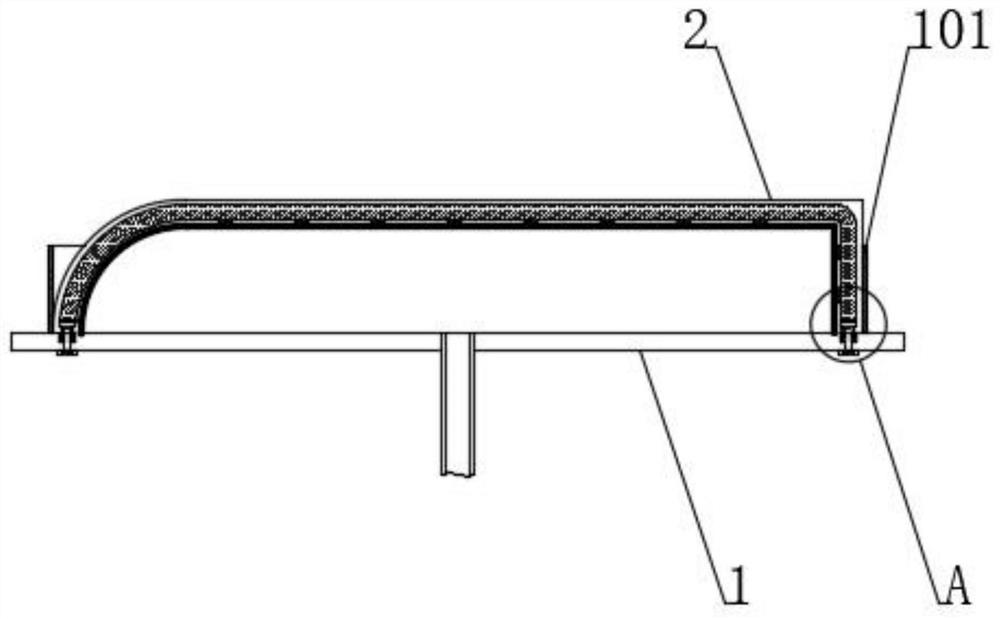

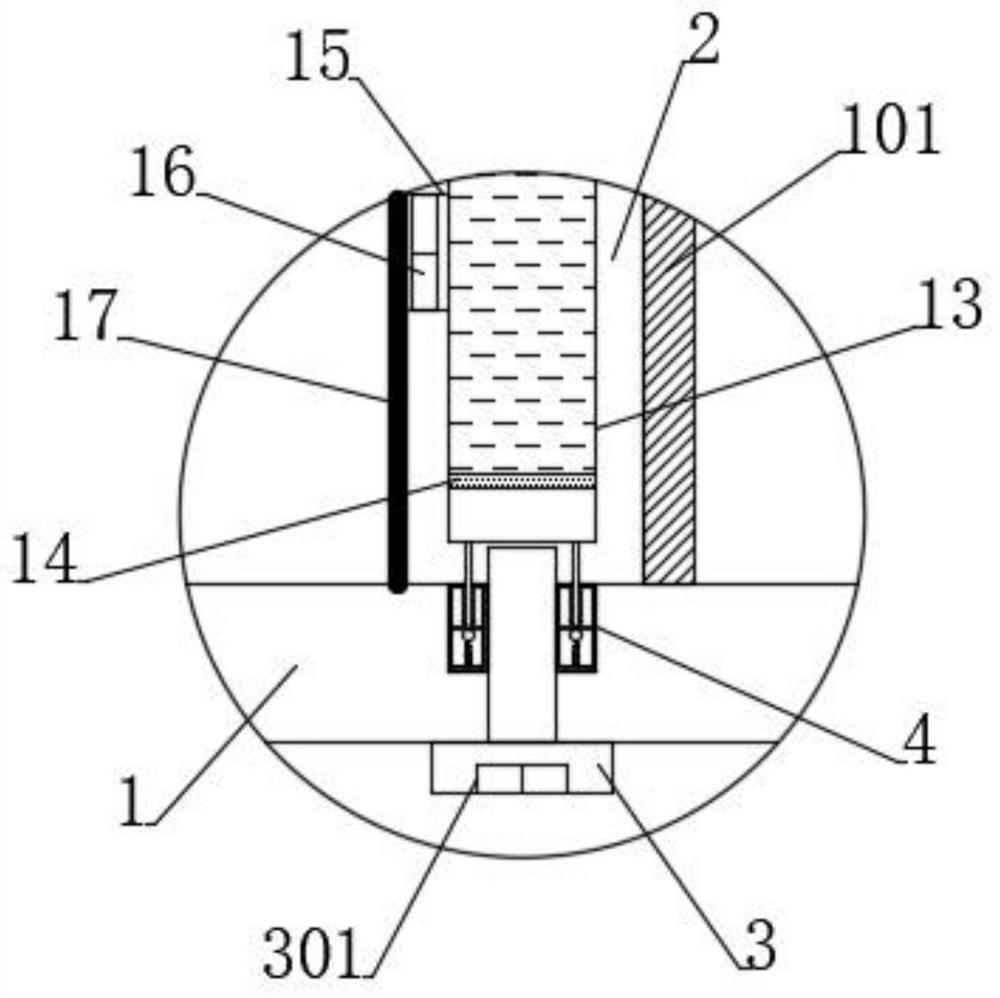

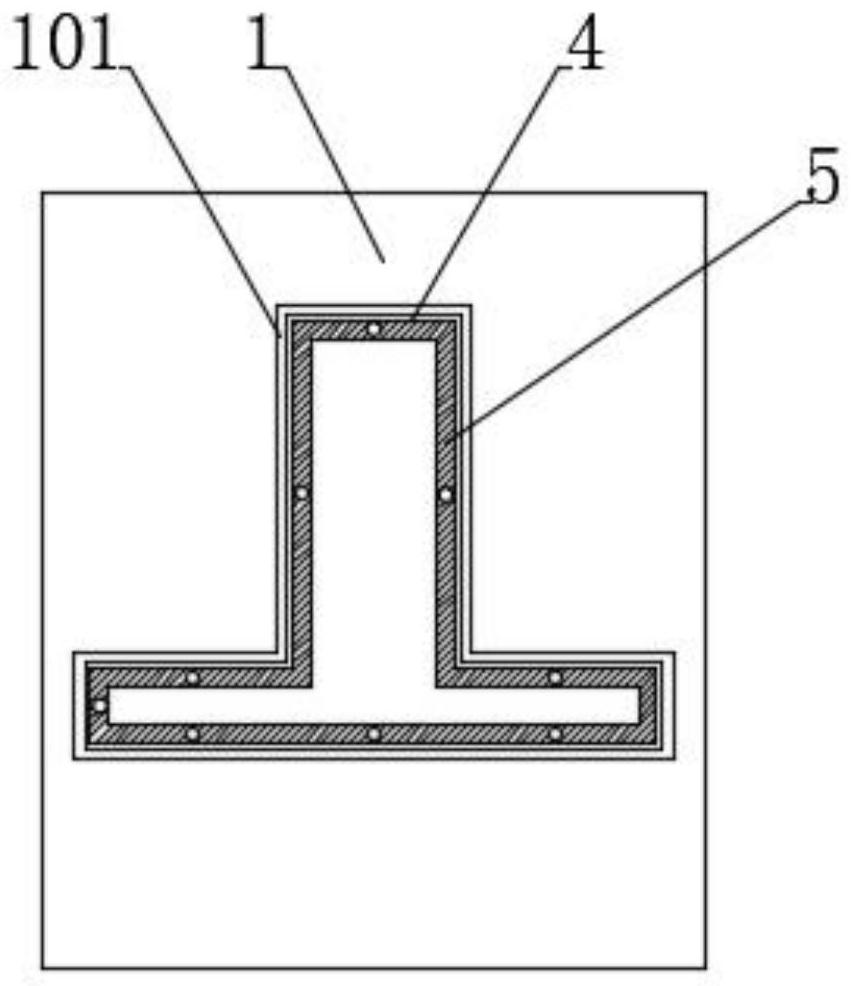

[0044] see Figure 1-5 , an injection mold for a display bracket shell, comprising a lower mold plate 1, a plastic addition hole is installed at the bottom of the lower mold plate 1, and is used for filling plastic between the lower mold plate 1 and the upper mold shell 2 during injection molding, and the lower mold The upper end of the plate 1 is provided with an upper mold shell 2, the lower mold plate 1 is embedded with a connecting screw 3, and the connecting screw 3 is threadedly connected with the upper mold shell 2, and the upper end of the lower mold plate 1 is dug with a storage side groove 4, and a storage side groove 4 There is a reaction bar frame 5 inside, the outer end of the reaction bar frame 5 is drilled with a threaded hole 6 penetrated by the connecting screw 3, the reaction bar frame 5 is dug with a built-in cavity 7, and the inner wall of the built-in cavity 7 is fixedly connected with a pre-sealed paper 8 , the bottom end of the built-in cavity 7 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com