A control method for steel defects in cold-rolled titanium-containing ultra-low carbon steel

A technology of ultra-low carbon steel and control methods, which is applied in the field of steelmaking technology, can solve the problems of product quality deterioration, and achieve the effect of product quality improvement and product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

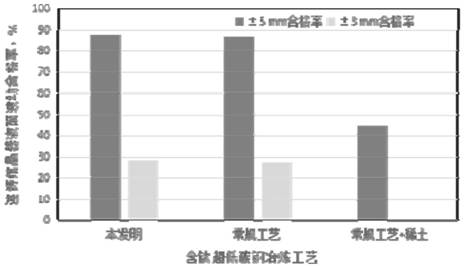

[0041] The method for controlling oxide inclusions in titanium-containing ultra-low carbon steel invented by the invention can ensure the stable and smooth running of steelmaking production, change the physical properties of oxide inclusions in the steel, thereby reducing the cold-rolled steel defect blocking rate of the final product, significantly To improve the quality of ultra-low carbon steel products.

[0042] For the production of titanium-containing ultra-low carbon steel, the process paths adopted in the present invention are: molten iron desulfurization, dephosphorization-converter decarburization-tapping, ladle top slag modification-vacuum decarburization, Ti deoxidation, Al addition and fine-tuning of components - Adding rare earth metals - continuous casting - hot rolling - pickling - cold rolling.

[0043] The typical furnace times of smelting using the present invention are as follows:

[0044] At the end of converter blowing, [%C]=280ppm, [%O]=550ppm; slag blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com