Split type encoder with automatic calibration function

An automatic calibration and encoder technology, applied in the encoder field, can solve the problems of split encoder installation errors and low output signal accuracy, and achieve the effect of not easy to lose codes, high output signal accuracy, and low heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained below in conjunction with specific embodiments, but the present invention is not limited thereto.

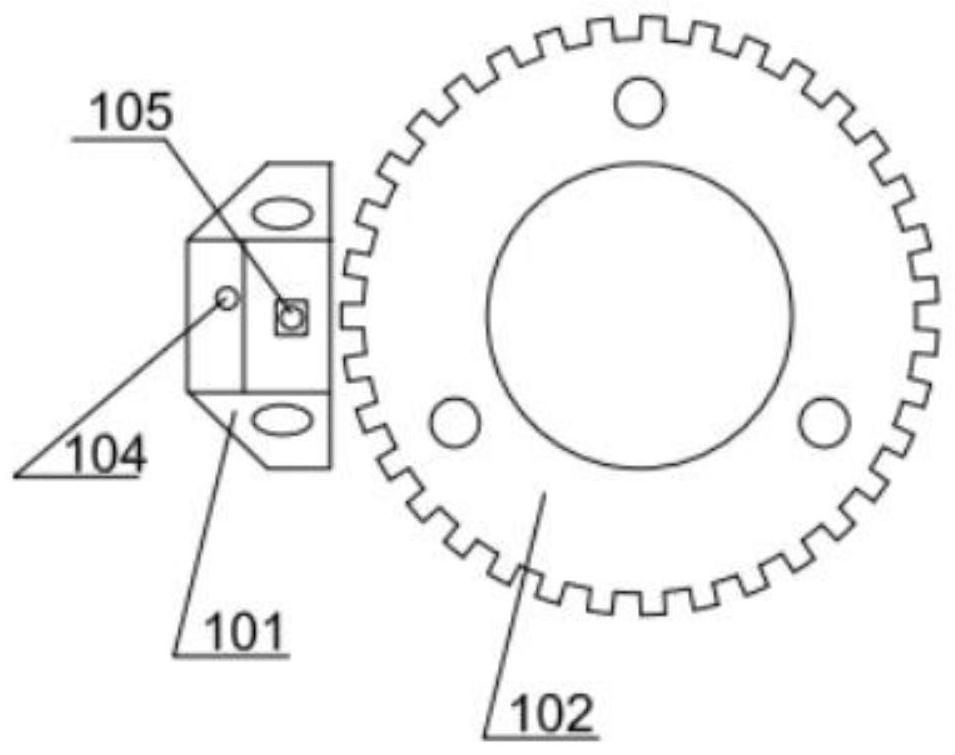

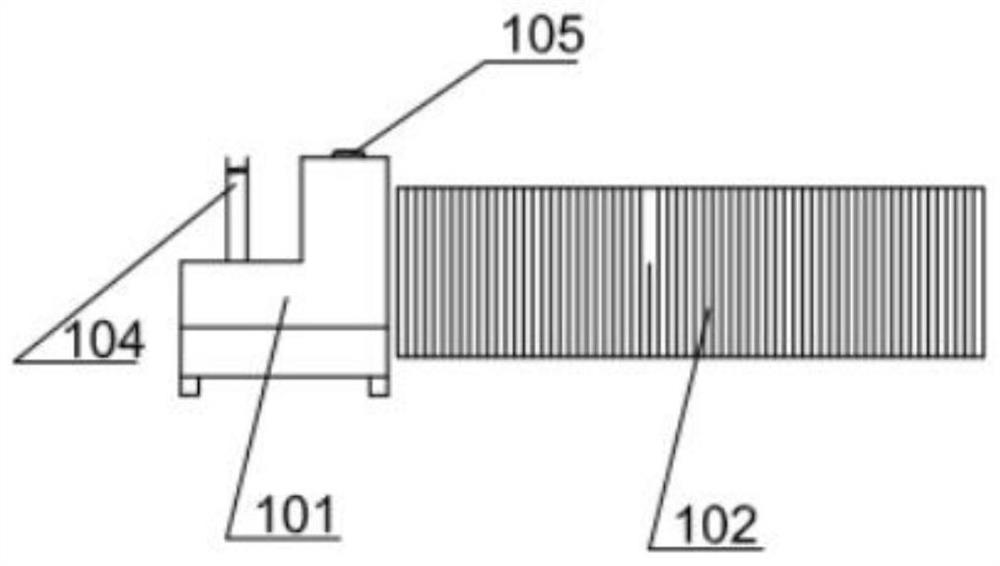

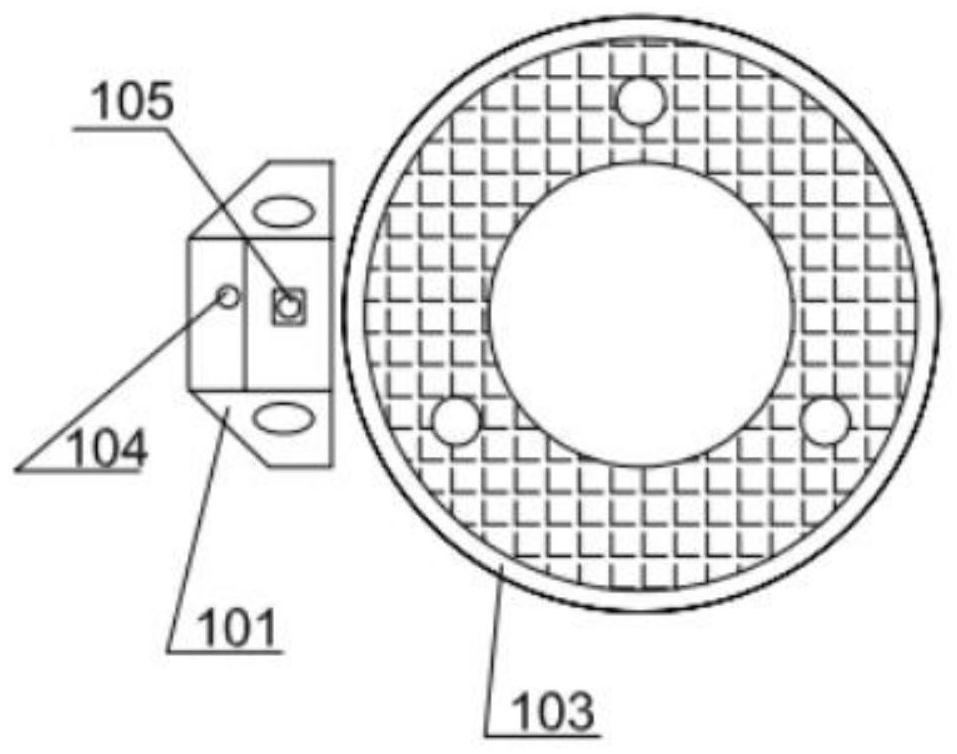

[0019] Such as Figure 1-5 As shown, the present invention provides a split encoder with an automatic calibration function, including: an encoder read head 101, a detection magnetic block, a calibration button 105 and a cable 104, the encoder read head 101 and the detection magnetic block It is a separate body and is used to output analog voltage signals. The calibration button 105 is located at one end of the upper surface of the encoder read head 101 and is used to calibrate the gain, phase, offset and other parameter values of the analog signal output by the reluctance. The cable 104 is located at the other end of the upper surface of the encoder read head 101, and is used to transmit the calibrated pulse signal, wherein the detection magnetic block is set on the drive shaft of the motor, wherein the encoder read head 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com