Secondary adjustable sugarcane juice crusher

An adjustable, pulverizer technology, applied in juice extraction, food science, application, etc., can solve the problems of low juice extraction efficiency, inconvenient cleaning, waste of sugarcane, etc., and achieve good crushing and exporting effects, not easy to block, and uniform crushing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

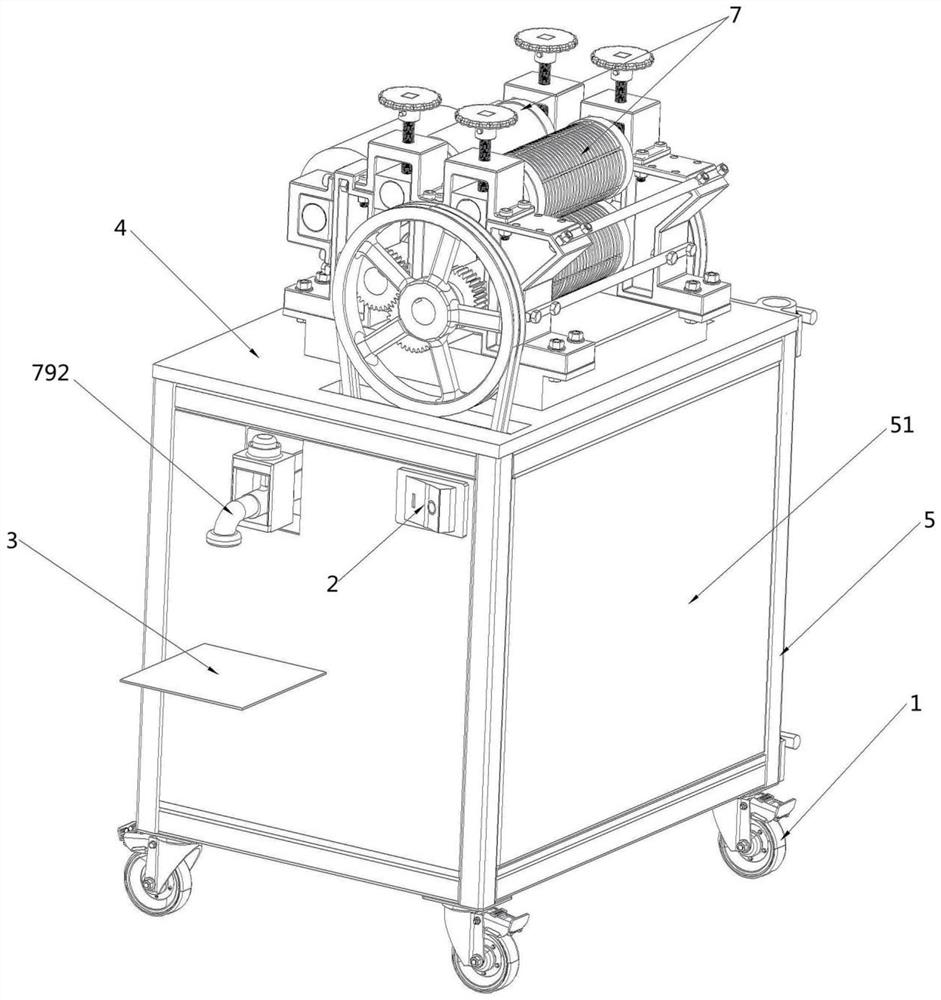

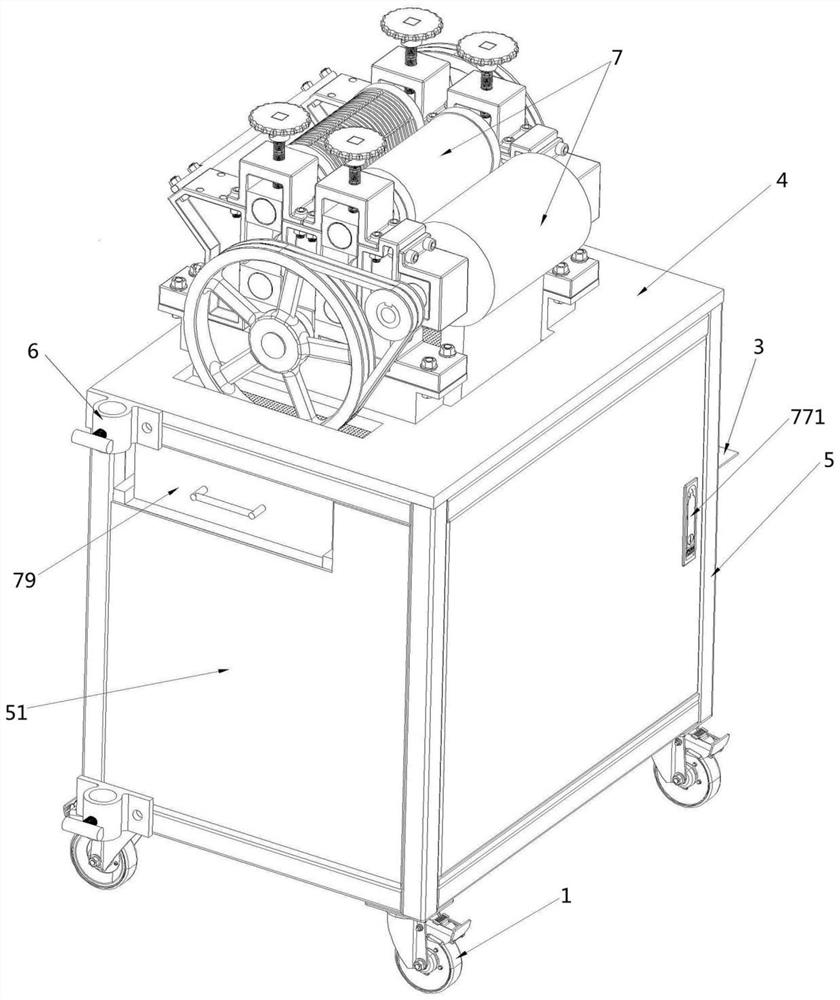

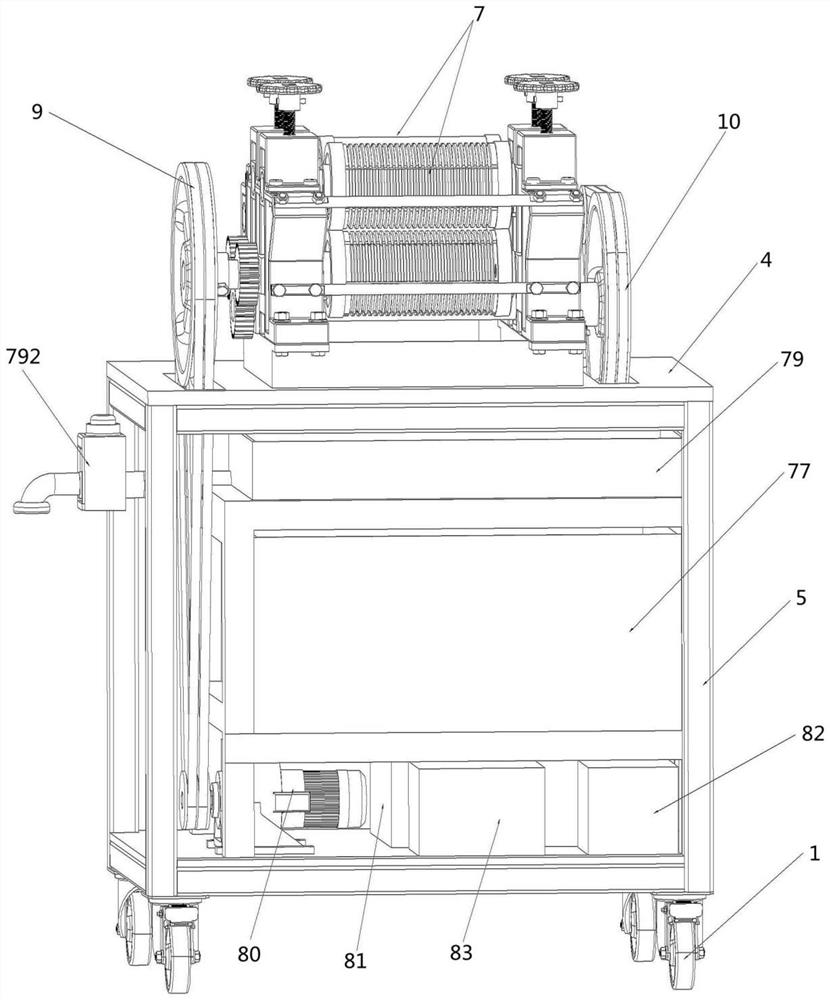

[0028] See attached figure 1 -12, a two-stage adjustable sugarcane juice crushing machine, characterized in that: it includes a juice crushing device installed on the platform board and a power supply device under the platform board;

[0029] The juicing and crushing device includes roller supports symmetrically and fixedly connected to the platform board. The guide roller group and the squeezing roller group are arranged side by side between the two roller bearings. Leak hole, one end of the lead-in roller shaft at the lower part of the lead-in roller group is coaxially sleeved with gear A and pulley A, the roller shaft at the lower end of the press roller group is connected with gear B, and the lower part between the two roller supports is connected with a rotating shaft One end of the rotating shaft is connected with gear C which meshes with gear A and gear B respectively, and the other end is connected with pulley B. Gear A drives gear B and gear C to rotate at the same ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com