Gas blanching pot capable of implementing linkage oil control

A blanching pan and gas technology, which is applied to the utensils for frying things in oil, household utensils, applications, etc., can solve the problems of hidden dangers of food safety, affecting the long-term effective progress of food processing, and inconvenient processing operations, etc., and achieve the improvement effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

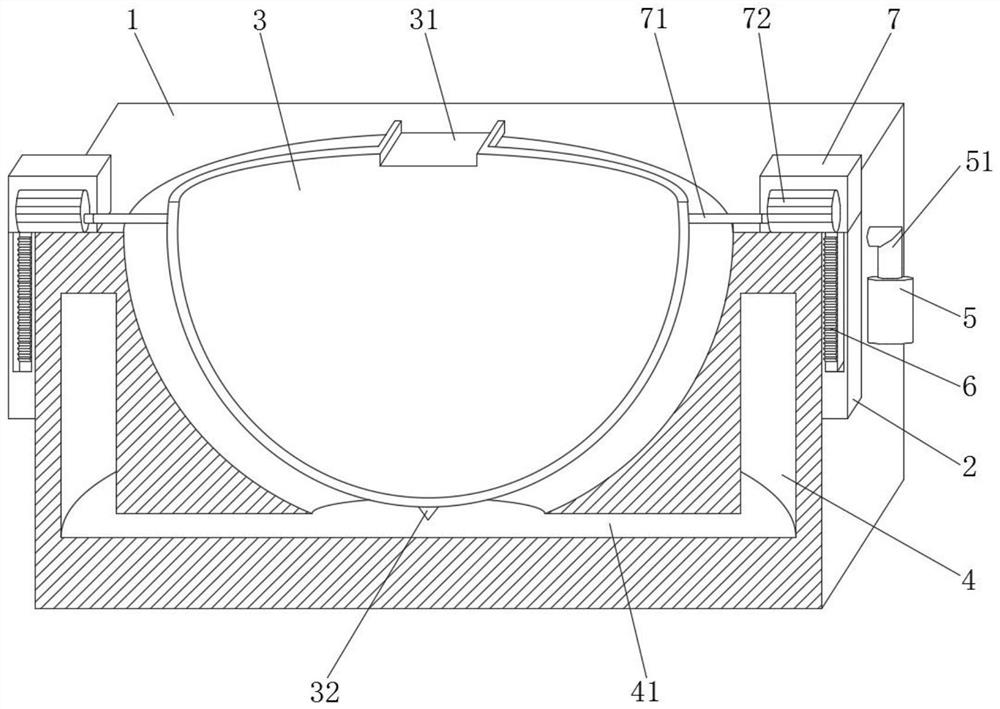

[0020] see Figure 1-2 , this embodiment provides a gas-fired blanching pot capable of implementing linkage oil control, including a scalding pot body 1, the outer wall of the scalding pot body 1 is equipped with a material cover 3 for holding materials through a connecting rod 2, and the outer wall of the material cover 3 There are oil holes, two connecting rods 2 are provided, and the two connecting rods 2 are arranged symmetrically on the outer wall of the hot pot body 1. Preferably, the two connecting rods 2 extend the diameter of the hot pot body 1 on the outer wall of the hot pot body 1. The direction of the hot pot is arranged symmetrically, the inside of the hot pot body 1 is provided with an oil tank 4 connected with the oil pan, and an air pump 5 is connected to the top of the oil tank 4 .

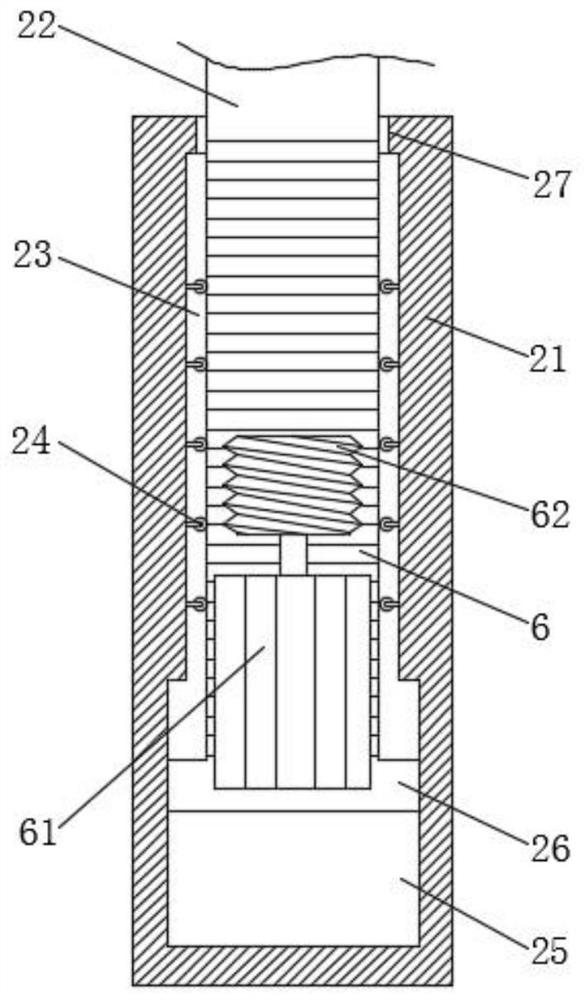

[0021] In order to realize the dragging of the connecting rod 2 to the material cover 3, the connecting rod 2 includes a fixed rod 21 and a movable rod 22. The inside of the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com