Control method for shape of thin hot-rolled structural steel plate

A control method and technology for structural steel plates, applied in the direction of profile control, etc., can solve the problems of increasing production costs, unable to solve the problem of plate shape, affecting the production efficiency of products, etc., to achieve the effect of reducing the plate shape problem and implementing low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

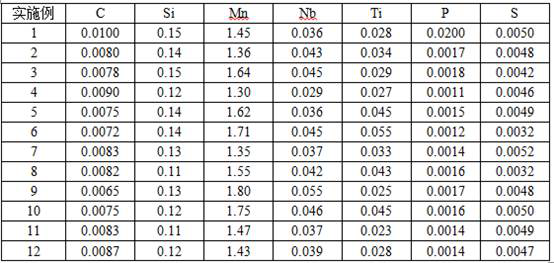

Embodiment 1~12

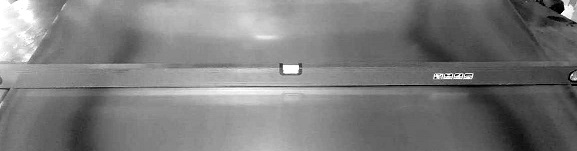

[0049] Examples 1-12 The thin-gauge hot-rolled structural steel plates produced by the method of the present invention have good shape, and the uncoiling wave height of the hot-rolled finished product is reduced to below 13 mm / m, which meets the needs of customers.

[0050] figure 2 It shows that after adopting the process of the present invention, the uncoiling shape of the hot-rolled raw material is good, the measured edge wave shape height is not more than 5mm, and the strip shape condition is obviously improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com