An electromagnetically driven soft punch liquid-filled deep drawing device and process method

An electromagnetic drive, liquid-filled deep drawing technology, applied in the field of machining and equipment, can solve the problems of reducing the surface quality and precision of the formed parts, low forming efficiency, small residual stress, etc., to achieve energy control and production automation, residual stress. The effect of low stress and high workpiece surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

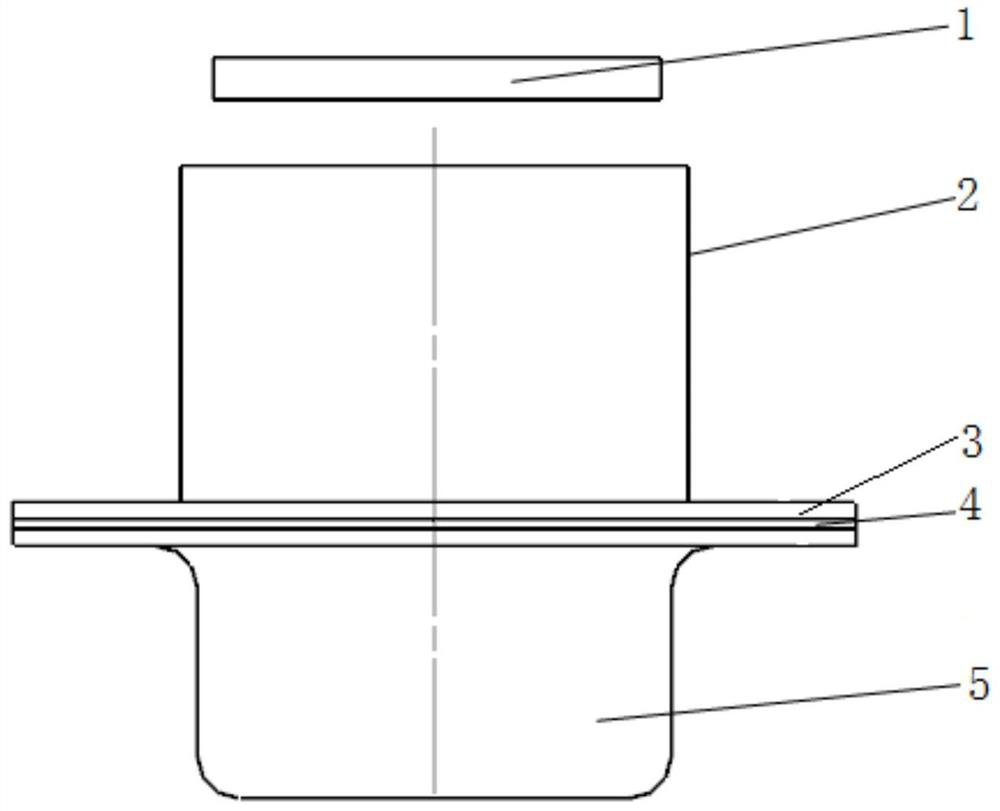

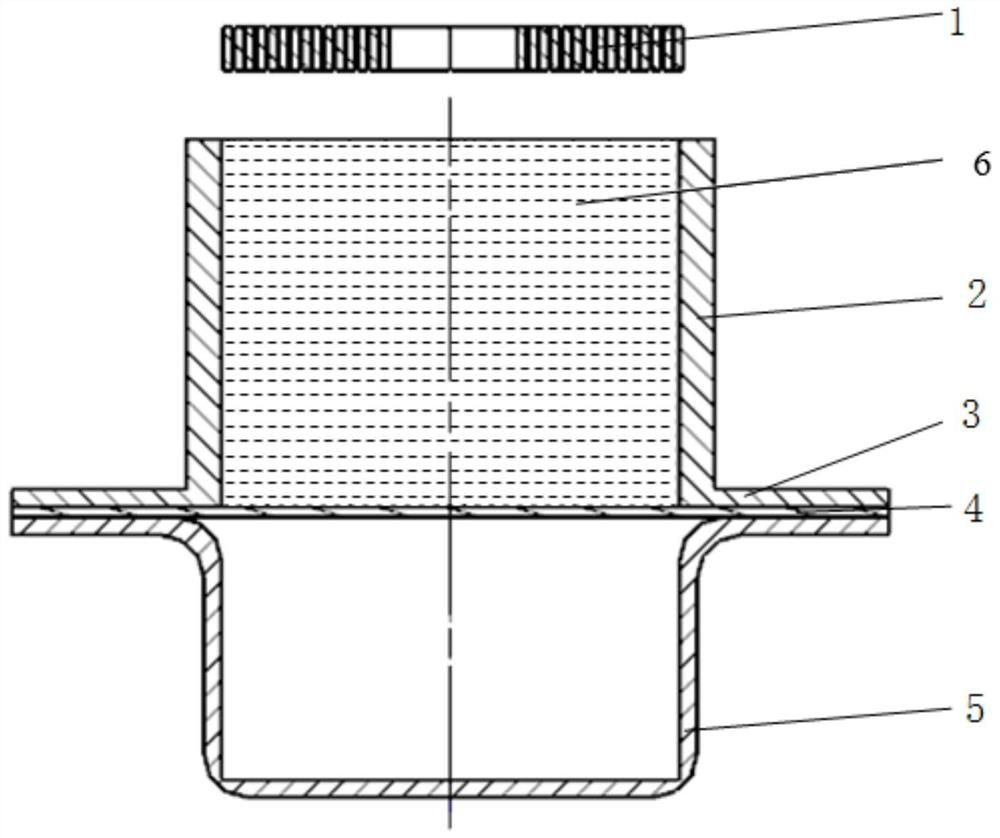

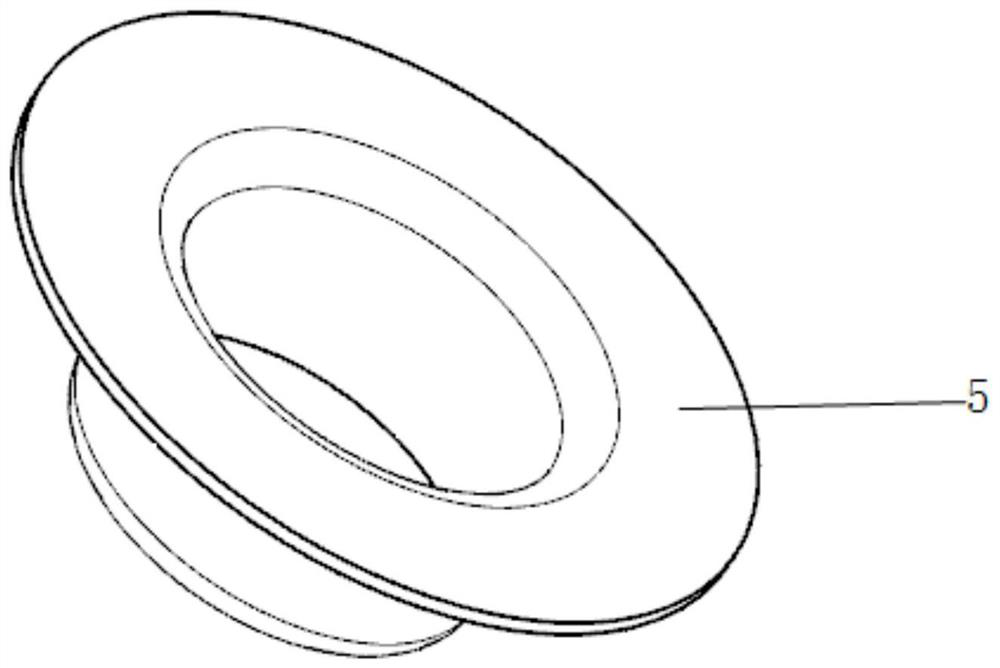

[0036] Such as Figure 1 to Figure 6 Shown: Taking the deep drawing of a cylindrical part as an example, the initial shape of the plate 4 is circular, the material is 6061 aluminum alloy, the diameter is 120 mm, the thickness is 1 mm, the inner diameter of the hydraulic chamber 2 is 40 mm, and the inner diameter of the die 5 is 40mm, the height is 20mm, the die 5 does not move, place the plate 4 between the die 5 and the blank holder 3, and apply pressure to press the plate 4, the blank holder 3 is a ring, the middle is hollow, in A cylinder whose end surface is parallel to the plate 4 and whose inner diameter is equal to the inner diameter of the blank holder 3 is welded on the ring as the hydraulic chamber 2, the inner diameter of the hydraulic chamber 2 coincides with the inner diameter of the blank holder 3, and the magnetic fluid 6 is poured into the hydraulic chamber 2, The plate coil 1, which is 1 mm away from the hydraulic chamber 2, is supplied with alternating curren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com