Slow cooling device for high-temperature knockout of steel castings

A technology of slow cooling devices and steel castings, which is applied in the field of slow cooling devices, can solve the problems of cumbersome steps, easily scalded workers, and increased investment in crane equipment, so as to protect safety, improve flexibility and adaptability, improve practicability and adaptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

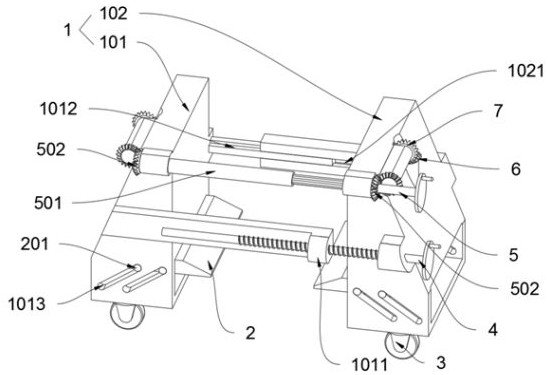

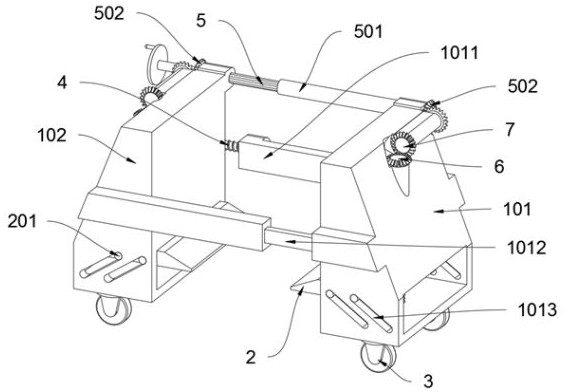

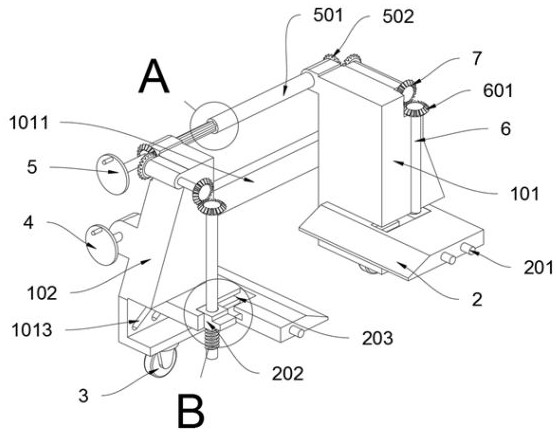

[0034] as attached figure 1 to attach Figure 7 Shown:

[0035]The invention provides a slow cooling device for high-temperature boxing of steel castings, which includes a support base 1, a support plate 2, a moving wheel 3, a length adjustment rod 4, a double-sided transmission rod 5, a lifting transmission rod 6 and a double-headed gear 7. The support seat 1 is composed of a left support 101 and a right support 102, and the left support 101 and the right support 102 are symmetrically designed; the support pallet 2 is plugged into the bottom of the support seat 1; the support pallet 2 There is a lifting block 202 inside, and the cross-sectional shape of the lifting block 202 is a "cross" shape. The inside of the supporting pallet 2 is provided with a long avoidance chute 203, and the lifting block 202 is inserted into the inside of the avoidance chute 203 , this design makes it not hinder the lifting of the lifting block 202 when the support pallet 2 rises or falls in an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com