Intelligent end face polishing equipment for aluminum profile machining

An aluminum profile processing and end face technology, which is applied in metal processing equipment, grinding/polishing equipment, surface polishing machine tools, etc., can solve the problems that mechanical lines affect the appearance quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

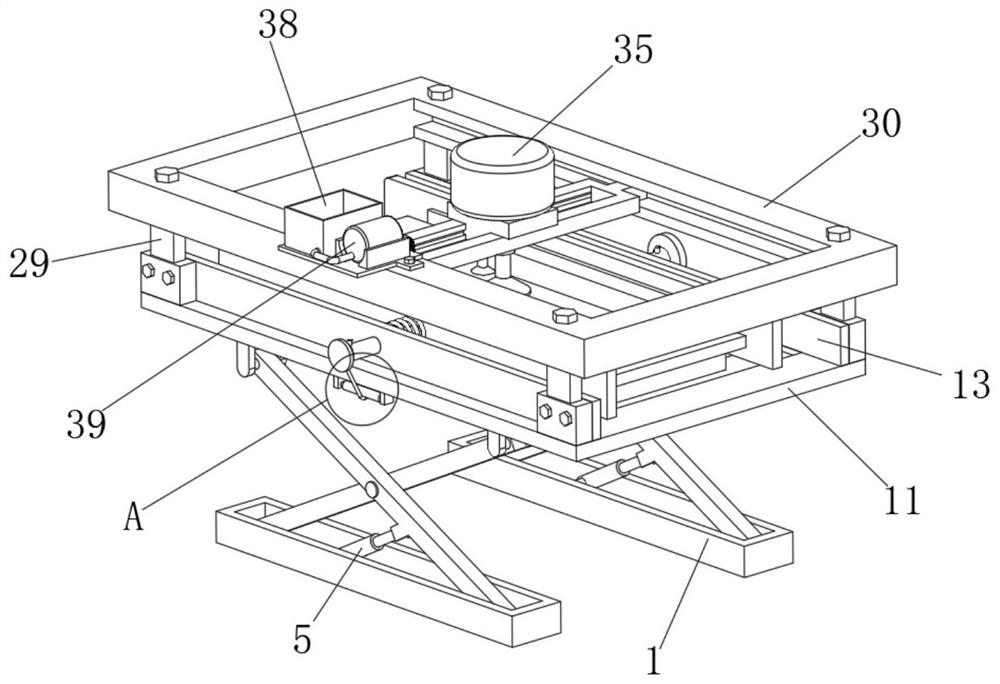

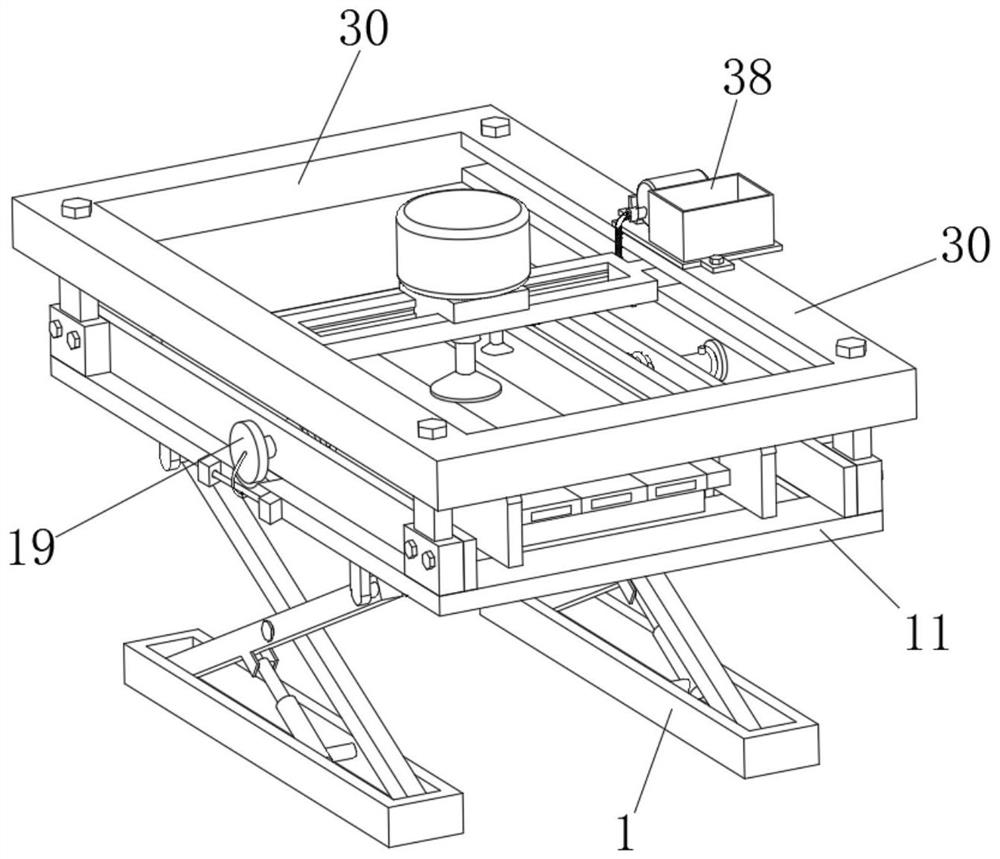

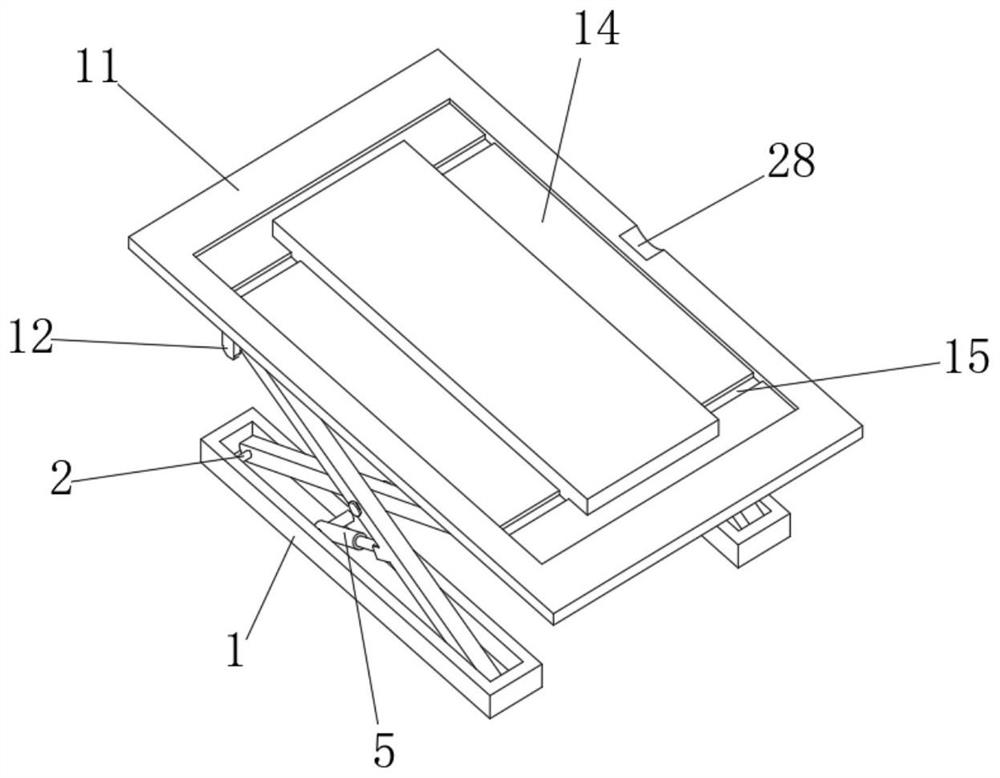

[0039] In a typical implementation of the present application, such as Figure 1-12 As shown, an intelligent end face polishing equipment for aluminum profile processing includes a support base 1, the same fixed shaft 2 is fixedly connected to the inner walls on both sides of the support base 1, and inner pillars are rotatably socketed on the two fixed shafts 2 3. The same lifting shaft 4 is fixedly connected to the inner walls on both sides of the two supporting bases 1, and the lifting cylinder 5 is rotatably connected to the two lifting shafts 4, and the lifting rod 6 is fixedly connected to one end of the two lifting cylinders 5, One side of the two inner pillars 3 is provided with an outer pillar 7, and the bottom ends of the two outer pillars 7 are respectively located in the two support bases 1, and the outer pillars 7 on the same side are crossed with the inner pillars 3, and the two outer pillars One side of 7 is fixedly connected with two fixed blocks 8, and the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com