Automatic marking device for mouse shell

A technology for printing labels and casings, applied in the directions of printing devices, printing, printing machines, etc., can solve the problems of low printing efficiency, difficult mouse fixation, and easy offset of printing label positions, so as to improve the degree of automation and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

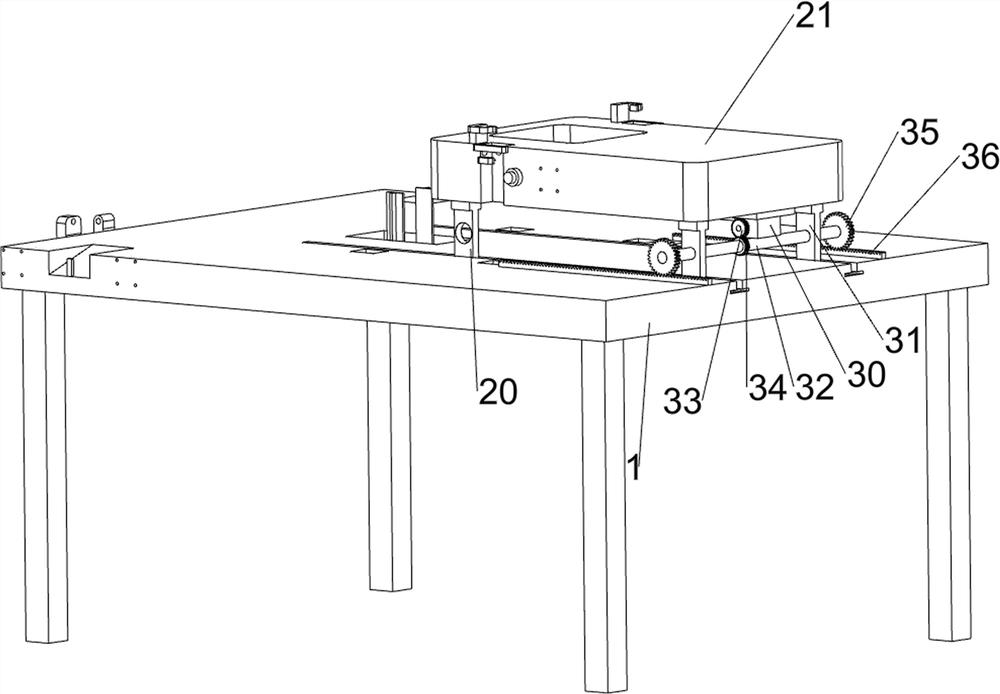

[0028] A kind of automatic marking device for mouse shell, such as figure 1 As shown, it includes a base 1 , a marking mechanism 2 and a moving mechanism 3 , the marking mechanism 2 is arranged on the top right side of the base 1 , and the moving mechanism 3 is arranged between the marking mechanism 2 and the base 1 .

[0029]The staff places the mouse on the designated position on the left side of the base 1, and then starts the moving mechanism 3 in the forward direction, and the moving mechanism 3 drives the marking mechanism 2 to move to a position close to the mouse, then stops the moving mechanism 3, and starts the marking mechanism 2 in the forward direction , the marking mechanism 2 prints the mouse shell, removes the mouse after the marking is completed, then reversely starts the marking mechanism 2, resets the marking mechanism 2, closes the marking mechanism 2 after resetting, and finally starts the moving mechanism in reverse 3. The moving mechanism 3 drives the ma...

Embodiment 2

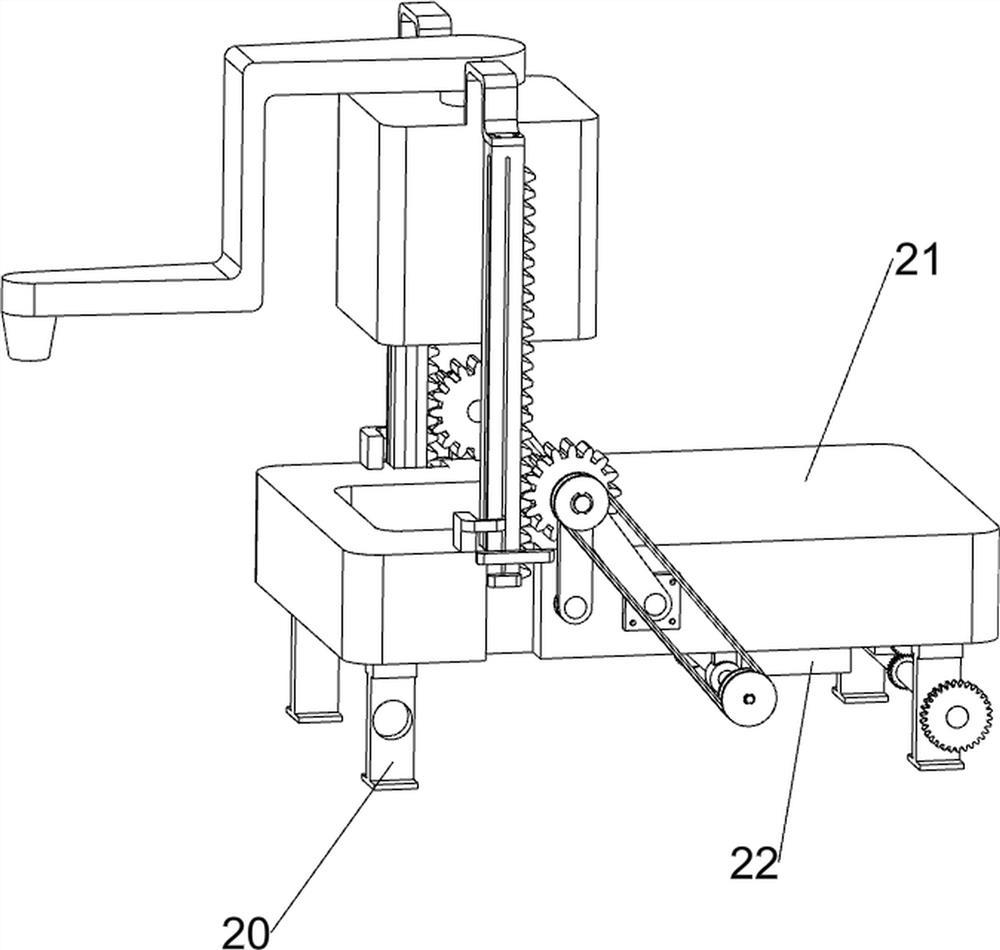

[0031] On the basis of Example 1, such as figure 2 , image 3 , Figure 4 and Figure 7 As shown, the marking mechanism 2 includes a first slider 20, a mounting table 21, a first servo motor 22, a first bearing seat 23, a first rotating shaft 24, a first bevel gear 25, a second bevel gear 26, a second bevel gear Bearing block 27, the first belt drive assembly 28, the first straight gear 29, the first tooth bar 210 and the mark table 211, base 1 top middle part sliding type is provided with a plurality of first slide blocks 20, the first slide block 20 and A mounting platform 21 is connected between the parts of the moving mechanism 3, the right part of the bottom of the mounting platform 21 is provided with a first servo motor 22, the bottom of the mounting platform 21 is symmetrically provided with a first bearing seat 23, and the first bearing seat 23 is connected with a first bearing seat 23. A rotating shaft 24, a first bevel gear 25 is connected to the output shaft of...

Embodiment 3

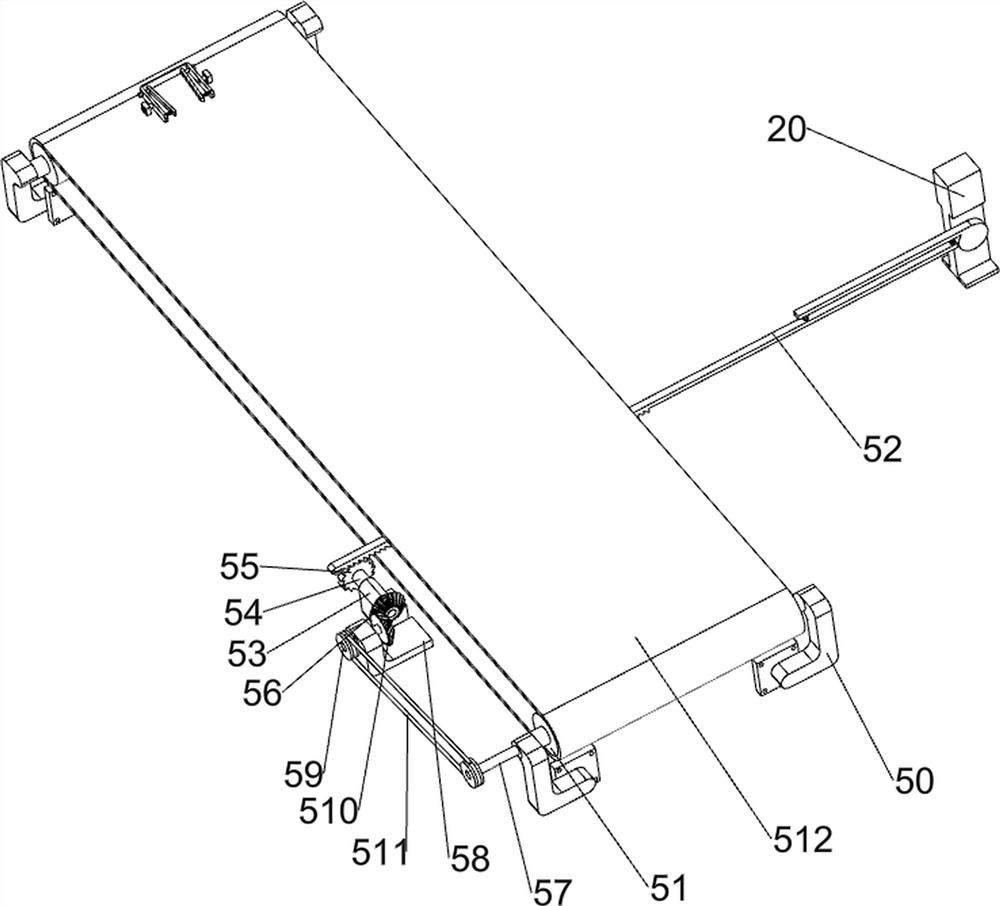

[0036] On the basis of Example 2, such as Figure 5 , Image 6 , Figure 7 , Figure 8 and Figure 9 As shown, a lifting mechanism 4 is also included. The bottom of the base 1 is provided with a lifting mechanism 4. The lifting mechanism 4 includes a first fixing assembly 40, a first spring 41, a third slider 42, a third rack 43, and a third bearing. Seat 44, third rotating shaft 45, fifth spur gear 46, second belt drive assembly 47, fourth bearing housing 48, fourth rotating shaft 49, sixth spur gear 410, fourth rack 411 and marking 412, base 1 The bottom is symmetrically provided with a first fixing component 40, and a third slider 42 is slidably connected to the first fixing component 40, and two first springs 41 are connected between the third slider 42 and the first fixing component 40, A third rack 43 is connected between the two third sliders 42, a third bearing seat 44 is connected to the middle part of the bottom of the base 1, a third shaft 45 is connected inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com