A kind of modified carbon black applied to spinning resin coloring and preparation method thereof

A technology of pigment carbon black and carbon black, which is applied in the field of modified carbon black colored by spinning resin and its preparation, can solve the problems of inability to remove impurities, low reaction grafting rate, steric hindrance of reactive groups, etc., and achieves novel structure. , the effect of easy dispersion performance

Active Publication Date: 2022-05-31

SHENYANG RES INST OF CHEM IND

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Its purpose and advantages are relatively obvious. The disadvantage is that the reaction grafting rate is low. Due to the inertness and porosity of carbon black itself, it will have a greater steric hindrance to the reactive group. When reacting with polymers, impurities Impossible to remove, the product quality is difficult to achieve the desired result

[0006] None of the above methods can be directly applied to the coloring of resin fibers, especially the dope coloring of filament fibers and fine denier filaments.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

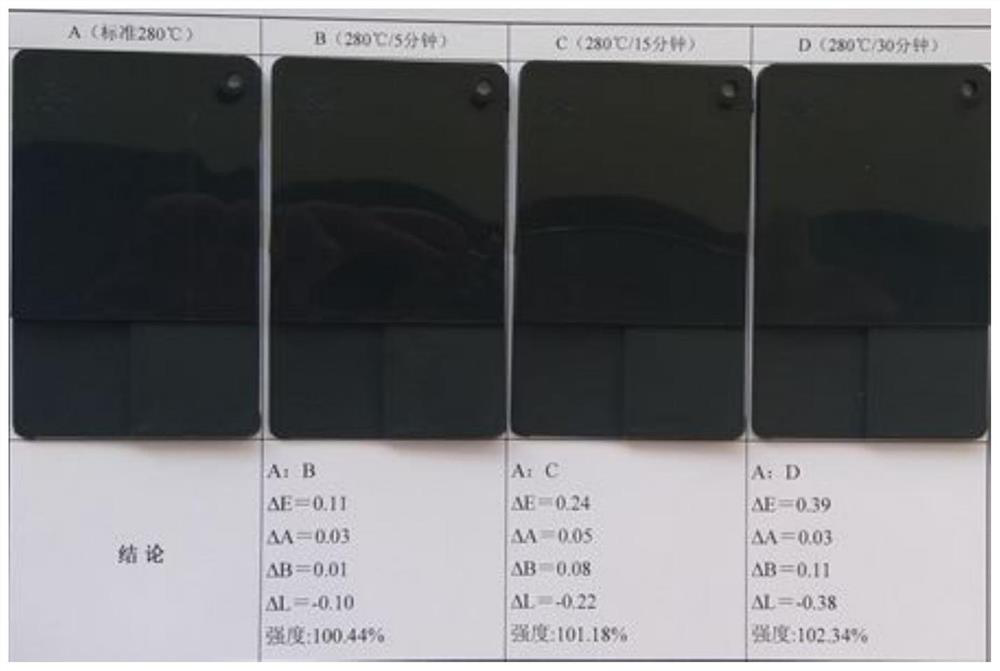

Effect test

Embodiment 1

[0046]

[0049]

Embodiment 2

[0054]

[0057]

Embodiment 3

[0062]

[0065]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

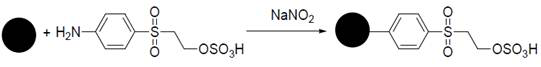

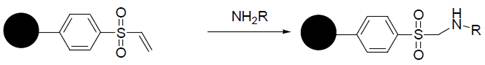

The invention belongs to a modified carbon black colorant and its preparation, in particular to a modified carbon black used in spinning resin coloring and a preparation method thereof. Modified carbon black is shown in formula I, wherein, ● is carbon black, R is C 1 -C 30 straight-chain alkyl, branched-chain alkyl or C 1 ~C 10 of alkylbenzenes. The colorant of the present invention is suitable for the coloring of resins. The colorant is blue-light black, and the colorant particles are soft. The dispersibility of the colorant is detected by a scraper fineness meter, and the dispersibility of the colorant is more obvious than that of carbon black before modification.

Description

A kind of modified carbon black applied to spinning resin coloring and preparation method thereof technical field The invention belongs to modified carbon black colorant and preparation, be specifically related to a kind of modified carbon that is applied to spinning resin coloring Black and its preparation method. Background technique The dope dyeing method is to add appropriate colorant in the spinning solution, after fully mixing, dissolving and filtering, it can also be added in the spinning solution. Before entering the spinneret, quantitatively inject colorant or colored dope, and after mixing in a static mixer, it is spun into colored fibers. This This process is a physical change, the advantage is that the coloring and spinning can be carried out continuously at the same time, the coloring is uniform, the color fastness is good, and the dyeing rate is high. The production cycle is short, the cost is low, and the pollution is less. It can make some highly or...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C01B32/05D01F1/04

CPCC01B32/05D01F1/04

Inventor 李文骁邢颖李学敏丛麟权马瑛

Owner SHENYANG RES INST OF CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com