A method for improving the weather resistance of decorative base paper titanium dioxide

A technology of decorating base paper and titanium dioxide, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve problems such as ideological constraints, and achieve the effects of reducing leakage, improving washing quality, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

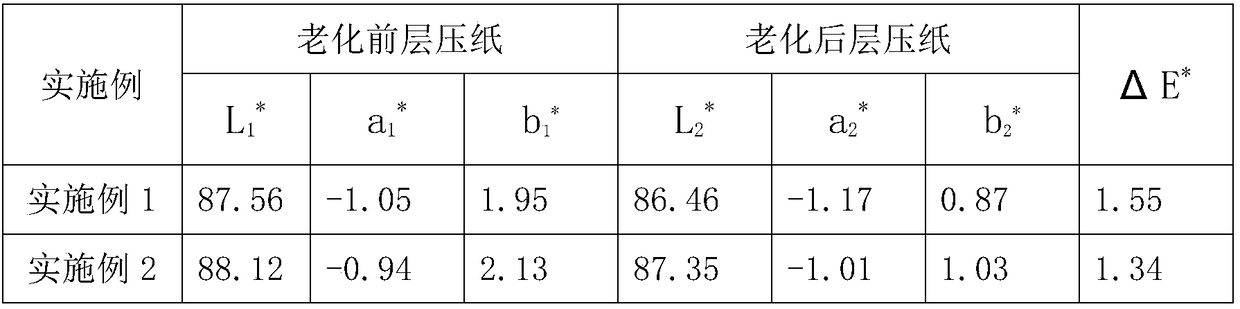

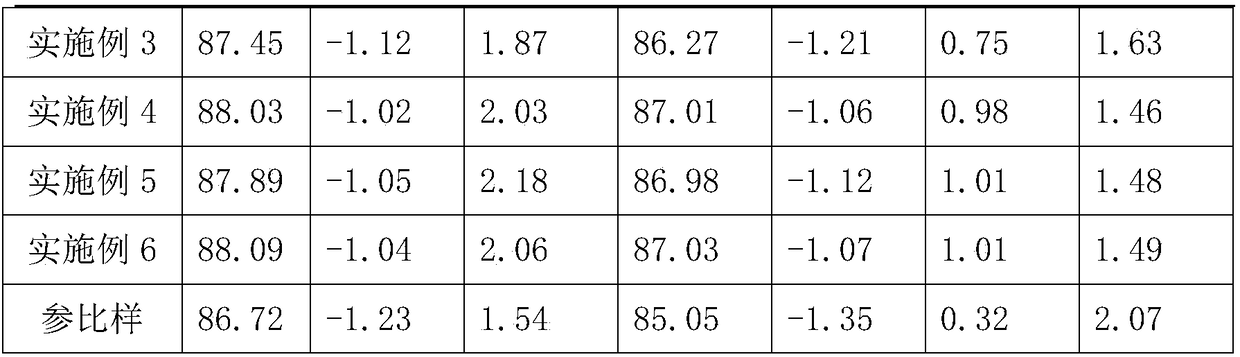

Examples

Embodiment 1

[0032] ⑴ Add TiO to the slurry after bleaching 2 Sol: Titanium dioxide sol concentration 105.5g / L, according to sol TiO 2 / Metatitanate TiO 2 The ratio is 2.0%, and titanium dioxide sol is added to the metatitanic acid slurry after bleaching.

[0033] ⑵Pulping of metatitanic acid after the second washing: take 1300g of metatitanic acid (TiO 2 31.5%), add 150ml of desalinated water, stir evenly to make about 370.3g / LTiO 2 Slurry.

[0034] ⑶ Add phosphoric acid: phosphoric acid concentration 84.6%, press 0.28%P 2 O 5 Add the proportions to the slurry and stir for 30 minutes.

[0035] ⑷Add potassium carbonate solution: the concentration of potassium carbonate solution is 485.2g / LK 2 O, press 0.4%K 2 O ratio was added to the slurry and stirred for 30 minutes.

[0036] ⑸Add aluminum sulfate: aluminum sulfate concentration 97.3g / L, press 0.4% Al 2 O 3 Add the proportions to the slurry and stir for 30 minutes.

[0037] ⑹ Membrane pressure filtration: salt treatment slurry membrane pressure fil...

Embodiment 2

[0041] ⑴ Add TiO to the slurry after bleaching 2 Sol: Titanium dioxide sol concentration 115.2g / L, according to sol TiO 2 / Metatitanate TiO 2 The proportion is 5.0%, and titanium dioxide sol is added to the metatitanic acid slurry after bleaching.

[0042] ⑵Pulping of metatitanic acid after the second washing: Take 1300g (TiO230.8%) of metatitanic acid for the second washing, add 150ml of demineralized water, and stir evenly to make about 359.6g / LTiO 2 Slurry.

[0043] ⑶ Add phosphoric acid: phosphoric acid concentration 84.6%, press 0.20%P 2 O 5 Add the proportions to the slurry and stir for 30 minutes.

[0044] ⑷Add potassium carbonate solution: the concentration of potassium carbonate solution is 462.8g / LK 2 O, press 0.5%K 2 O ratio was added to the slurry and stirred for 30 minutes.

[0045] ⑸Add aluminum sulfate: aluminum sulfate concentration 98.6g / L, 0.5% Al 2 O 3 Add the proportions to the slurry and stir for 30 minutes.

[0046] ⑹ Membrane pressure filtration: the salt treatmen...

Embodiment 3

[0050] ⑴ Add TiO to the slurry after bleaching 2 Sol: Titanium dioxide sol concentration 125.3g / L, according to sol TiO 2 / Metatitanate TiO 2 The proportion is 4.0%, and titanium dioxide sol is added to the metatitanic acid slurry after bleaching.

[0051] ⑵Pulping of metatitanic acid after the second washing: take 1300g of metatitanic acid (TiO 2 32.4%), add 300ml of demineralized water, stir evenly to make about 338.0g / LTiO 2 Slurry.

[0052] ⑶ Add phosphoric acid: phosphoric acid concentration 84.6%, press 0.25% P 2 O 5 Add the proportions to the slurry and stir for 30 minutes.

[0053] ⑷Add potassium carbonate solution: the concentration of potassium carbonate solution is 495.3g / LK 2 O, press 0.3%K 2 O ratio was added to the slurry and stirred for 30 minutes.

[0054] ⑸Add aluminum sulfate: the concentration of aluminum sulfate is 105.1g / L, at 0.5% Al 2 O 3 Add the proportions to the slurry and stir for 30 minutes.

[0055] ⑹ Diaphragm pressure filtration: salt treatment slurry diap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com