A method for preparing transparent pigment yellow 180

A yellow and transparent technology for pigments, applied in the direction of organic dyes, etc., can solve the problems of insufficient color of pigments, difficulty in solvent recovery, general tinting strength, etc., and achieve bright color, fast and thorough crystal transformation, and small pigment particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

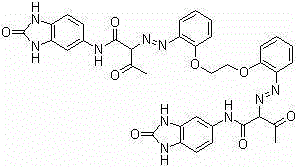

Image

Examples

Embodiment 1

[0023] Take 24.5g of ethylene glycol (2,2'-diamino)diphenyl ether, add 50g of HCI (36%), add 500mL of water to dissolve, cool to 0~5°C, add NANO 2 To its excess, after stirring for 3 hours, react with urea to remove the filtered nitrous acid, then decolorize and filter to obtain a diazonium salt solution, add ice water to adjust the volume to 1000mL, and set aside.

[0024] Take 57.2 g of 5-acetoacetamidobenzimidazolone, add it to 500 mL of water, add 37.3 g of potassium hydroxide to dissolve and filter it, collect the filtrate and add purified water to adjust the volume to 1050 mL, and set aside.

[0025] Take 107g of ammonium chloride, add it to 2000mL of water, add 5g of di-octadecyl-dimethylammonium chloride, 30g of 28% ammonia water, make it into a buffer solution, control the temperature at 25-30°C and start dripping Add 50mL of coupling solution, then add diazonium solution and coupling solution dropwise at the same time, after 4h dropwise addition, continue stirring fo...

Embodiment 2

[0028] Take 24.5g of ethylene glycol (2,2'-diamino)diphenyl ether, add 60g of HCI (36%), add 500mL of water to dissolve, cool to 0~5°C, add NANO 2 To its excess, after stirring for 3 hours, react with urea to remove the filtered nitrous acid, then decolorize and filter to obtain a diazonium salt solution, add ice water to adjust the volume to 1000mL for later use.

[0029] Take 57.2 g of 5-acetoacetamidobenzimidazolone, add it to 500 mL of water, add 44.7 g of potassium hydroxide to dissolve it and filter it, collect the filtrate and add purified water to adjust the volume to 1100 mL, and set aside.

[0030] Take 153g of ammonium chloride, add it to 2000mL of water, add 5g of di-octadecyl-dimethylammonium chloride, 45g of 28% ammonia water, make it into a buffer solution, control the temperature at 30-35°C and start dripping Add 100mL of coupling solution, then add diazonium solution and coupling solution dropwise at the same time, after 6h dropwise addition, continue to stir ...

Embodiment 3

[0033] Take 24.5g of ethylene glycol (2,2'-diamino)diphenyl ether, add 75g of HCI (36%), add 500mL of water to dissolve, cool to 0~5°C, add NANO 2 To its excess, after stirring for 3 hours, react with urea to remove the filtered nitrous acid, then decolorize and filter to obtain a diazonium salt solution, add ice water to adjust the volume to 1000mL for later use.

[0034] Take 57.2 g of 5-acetoacetamidobenzimidazolone, add it to 500 mL of water, add 56.0 g of potassium hydroxide to dissolve it and filter it, collect the filtrate and add purified water to adjust the volume to 1075 mL, and set aside.

[0035] Take 214g of ammonium chloride, add it to 2000mL of water, add 5g of di-octadecyl-dimethylammonium chloride, 60g of 28% ammonia water, and make it into a buffer solution. Control the temperature at 15-18°C and start dripping Add 75mL of coupling solution, then add diazonium solution and coupling solution dropwise at the same time, after 6h dropwise addition, continue stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com