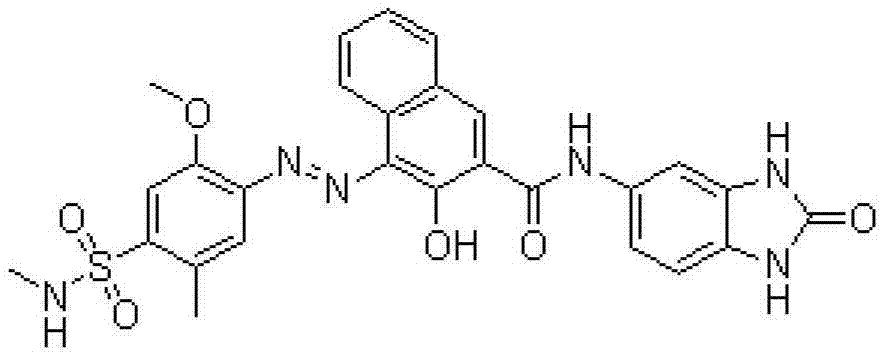

A preparation method of brilliant blue light red organic pigment c.i.p.r.185

A technology of organic pigments and blue light, which is applied in organic dyes, chemical instruments and methods, azo dyes, etc., can solve the problems of diazonium salts not responding in time, poor pigment performance, and large amount of acid and alkali, etc., to achieve fine particle size, Effects of fastness improvement and purity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing brilliant blue light red organic pigment C.I.P.R.185, comprising the following steps:

[0024] 1) Take 24.0g of methanesulfonamide crixidin, add it to 800mL of water, add 80g of acetic acid after dispersion, cool to 0°C, add NaNO with a concentration of 31% dropwise 2 to a slight excess; after stirring for 1-3 hours, add urea to remove excess NaNO 2 , then add 5% activated carbon for decolorization for 1 h, filter to obtain the diazonium salt filtrate and refrigerate for later use;

[0025] 2) Take 35g naphthol ASBI, add it to 800mL water, add 0.3g octadecane polyvinyl chloride ether, add KOH24g to dissolve after dispersion, and then filter to obtain the coupling component solution;

[0026] 3) Stir and mix 50g of ammonia water with a concentration of 27%, 90g of ammonium chloride, 2.5g of octadecane polyvinyl chloride ether and 1.5L of water, and adjust the temperature to 45°C to obtain a buffer solution;

[0027] 4) Add the diazonium salt filt...

Embodiment 2

[0030] A method for preparing brilliant blue light red organic pigment C.I.P.R.185 comprises the following steps:

[0031] 1) Take 24.0g of methanesulfonamide crixidin, add it to 800mL of water, add 80g of acetic acid after dispersion, cool to 0°C, add NaNO with a concentration of 31% dropwise 2 to a slight excess; after stirring for 1-3 hours, add urea to remove excess NaNO 2 , add 5% activated carbon for decolorization for 1 h, filter to obtain the diazonium salt filtrate and refrigerate for later use;

[0032] 2) Take 35g of naphthol ASBI, add it to 800mL of water, add 0.3g of octadecane polyoxyethylene ether, add KOH20g to dissolve after dispersion, and then filter to obtain the coupling component solution;

[0033] 3) Stir and mix 50g of ammonia water with a concentration of 27%, 90g of ammonium chloride, 3.5g of hexadecane polyoxyethylene ether and 1.5L of water, and adjust the temperature to 45°C to obtain a buffer solution;

[0034] 4) Add the diazonium salt filtrate...

Embodiment 3

[0037] A method for preparing brilliant blue light red organic pigment C.I.P.R.185 comprises the following steps:

[0038] 1) Take 24.0g of methanesulfonamide crixidin, add it to 800mL of water, add 90g of acetic acid after dispersion, cool to 0°C, add dropwise NaNO with a concentration of 31% 2 to a slight excess; after stirring for 1-3 hours, add urea to remove excess NaNO 2 , add 5% activated carbon for decolorization for 1 h, filter to obtain the diazonium salt filtrate and refrigerate for later use;

[0039] 2) Take 35g of naphthol ASBI, add it to 800mL of water, add 0.3g of octadecane polyoxyethylene ether, add KOH20g to dissolve after dispersion, and then filter to obtain the coupling component solution;

[0040] 3) Stir and mix 50g of ammonia water with a concentration of 27%, 90g of ammonium chloride, 3.5g of dodecane polyvinyl chloride ether and 1.5L of water, and adjust the temperature to 60°C to obtain a buffer solution;

[0041] 4) Add the diazonium salt filtrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com