Electric actuator used for thermoelectric transmission system

An electric actuator and transmission system technology, applied in heat exchange equipment, engine components, non-rotational vibration suppression, etc., can solve the problems of easy damage at the interface, inconvenient installation, etc., to achieve simple connection, prolong service life, and avoid thermal expansion. cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

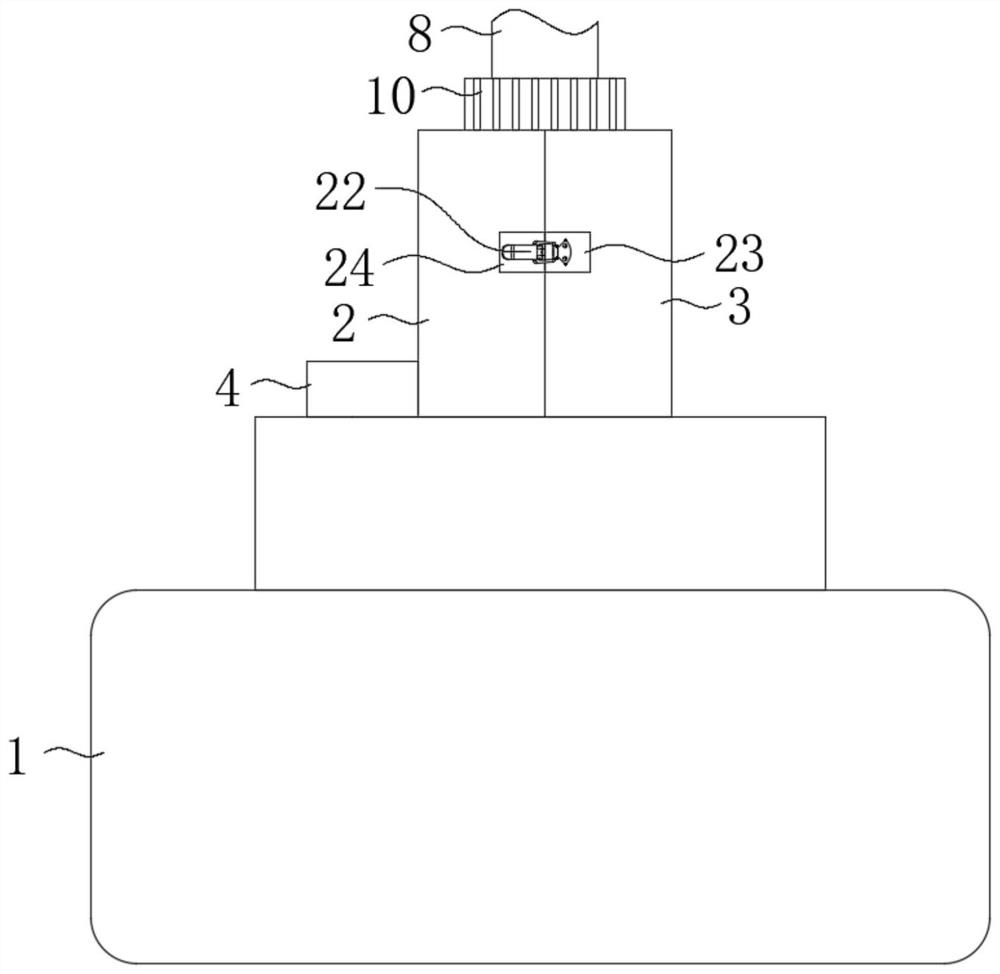

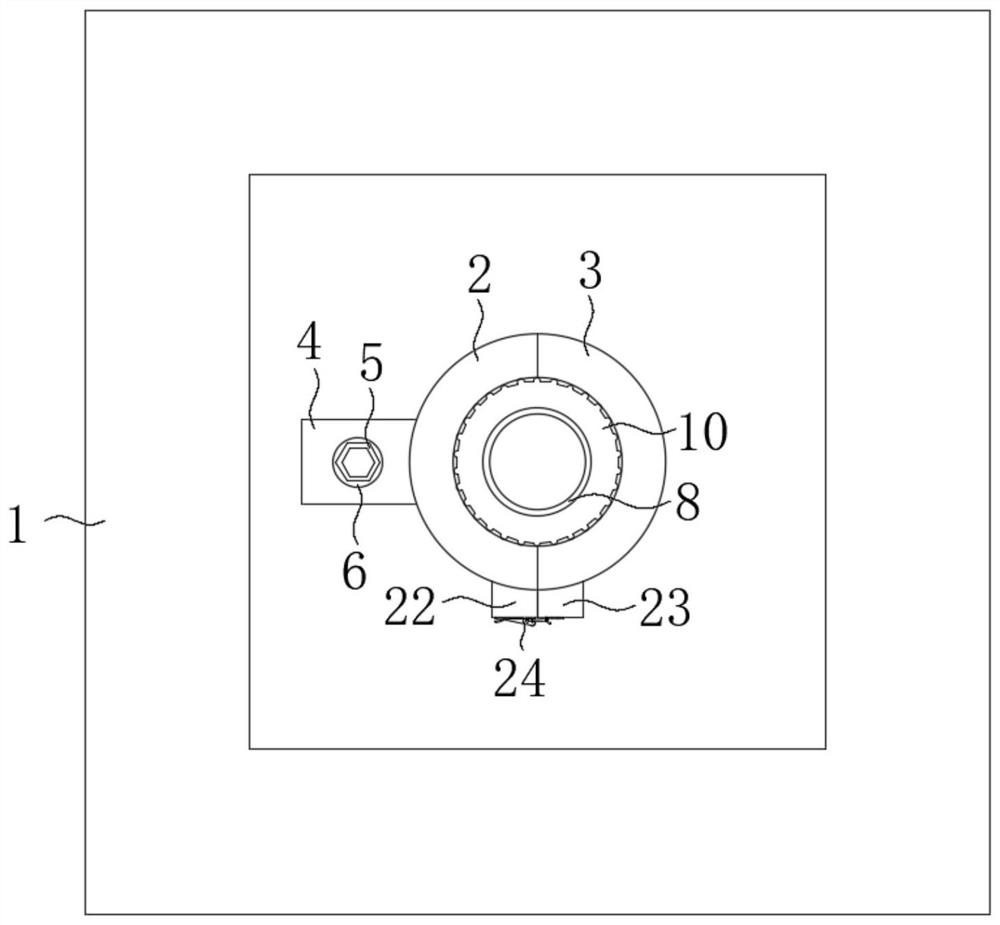

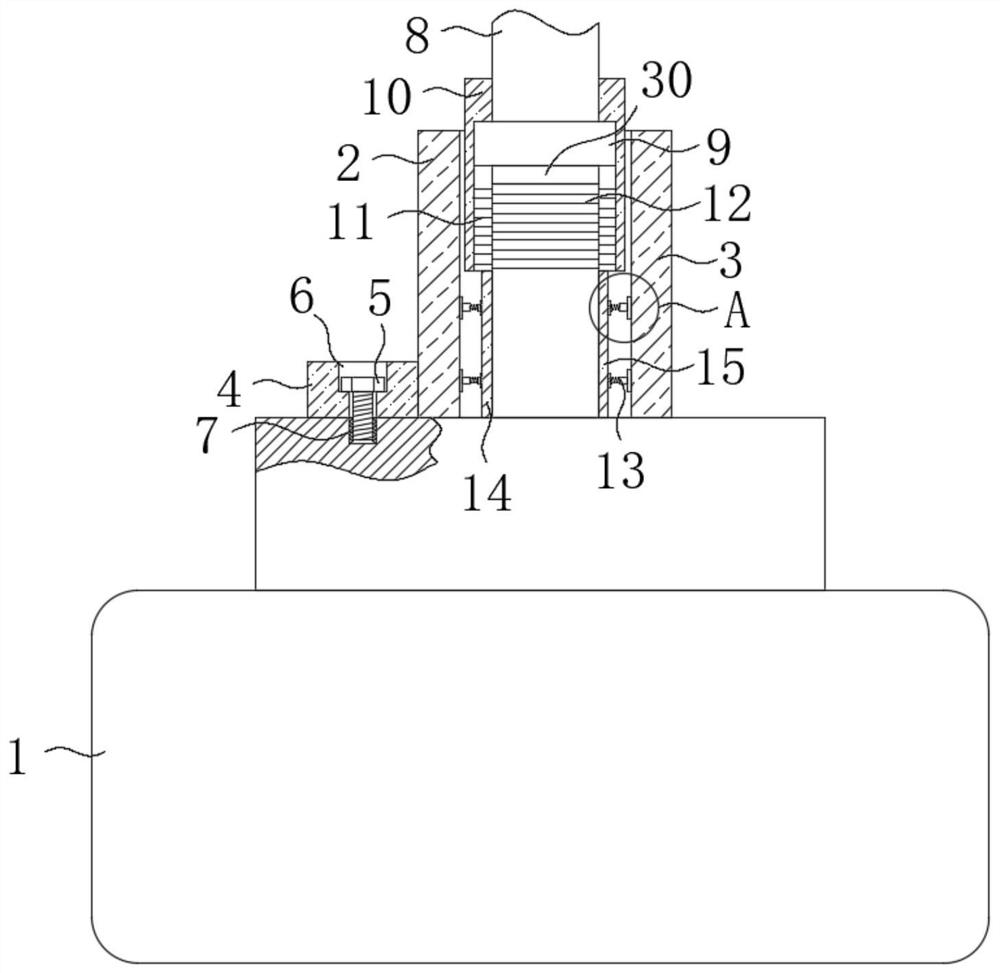

[0029] The present invention provides Figure 1-6 A electric actuator for a thermoelectric transmission system includes an electric actuator housing 1 and a piping conduit 8, and an upper end of the electric actuator housing 1 is provided with a first protective housing 2 and a second protective housing 3. The first protective housing 2 and the second protective housing 3 are hinged by a hinge, and the first protective housing 2 is fixed to the upper end of the electric actuator housing 1, and one end of the transfer pipe 8 is at the interface of the electric actuator. The connection is disassembled, and the pipe 8 is inner communication with the electro-actuator, and the first protective housing 2 and the second protective housing 3 constitute a cylinder, and the interface of the transfer pipe 8 and the electric actuator is located in the first protection. The inner portion of the cylinder composed of the outer casing 2 and the second protective housing 3 is for protection for the...

Embodiment 2

[0039] Such as Figure 7 As shown, different from Example 1 is:

[0040] The fixing assembly includes a fixing block 4, a screw 25, and a screw sleeve 26, and the fixing block 4 is fixed to the outer wall of the first protective housing 2, and there is a through hole in the inside of the fixing block 4, and the screw 25 is fixed to the electric actuator housing 1. On the outer wall, one end of the screw 25 penetrates through the through hole and extends to the outside of the through hole, and the second threaded hole 27 is opened inside the screw sleeve 26, and one end of the screw 25 is threaded to the inside of the second threaded hole 27, only need to take The lower screw sleeve 26 can fix and disassemble the first protective housing 2, very convenient;

[0041] On one side of the annular stop 9, an annular groove 28 is provided with an annular slot 29 at an interface of the electric actuator, and the annular block 29 is located inside the annular groove 28, and the annular blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com