A self-adaptive control method for wind speed of DC frequency conversion gas water heater

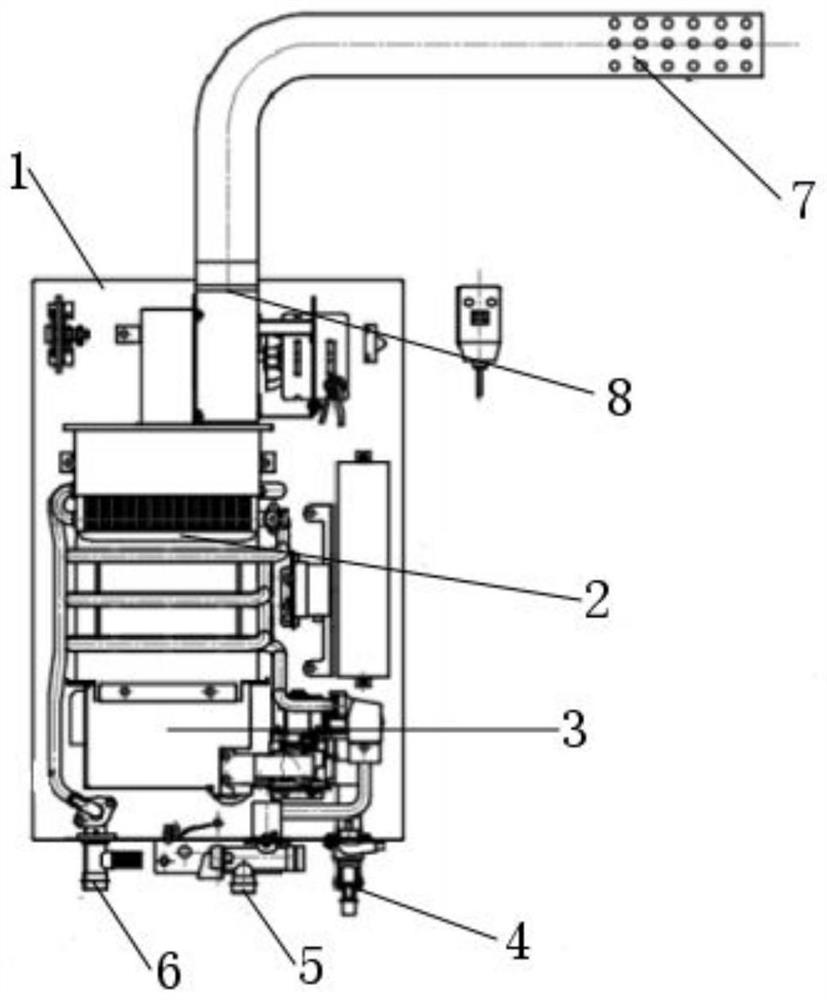

A gas water heater and direct current frequency conversion technology, which is applied to the wind speed control of gas water heaters and the wind speed adaptive control field of direct current variable frequency gas water heaters, can solve problems such as unsmooth discharge, untimely alarm, unstable combustion, etc. Reasonable design to improve the effect of combustion wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

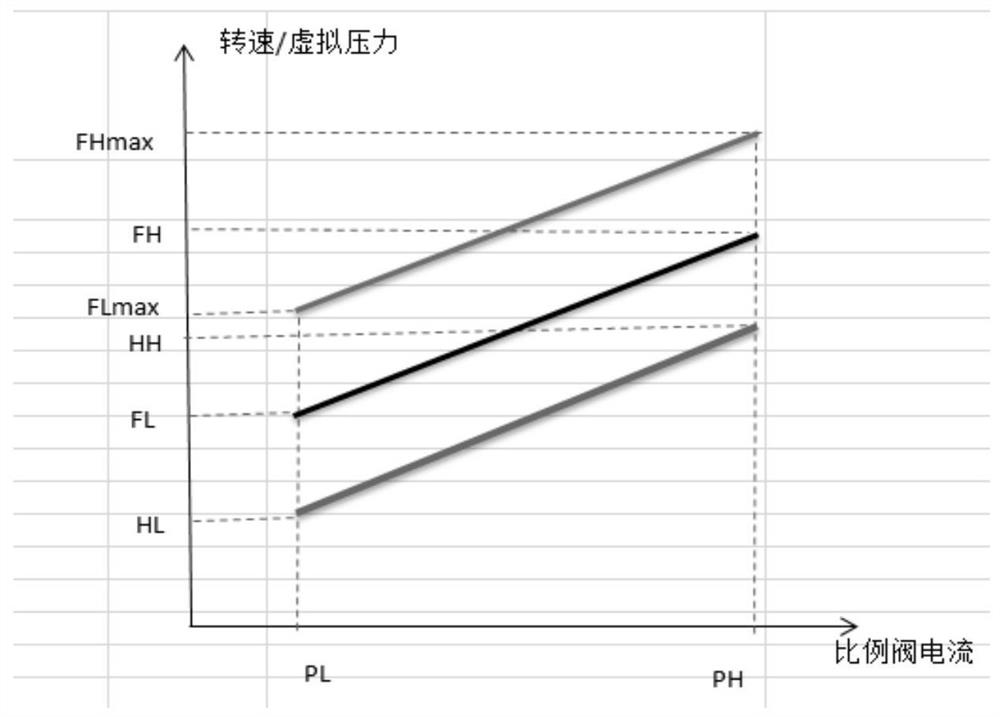

[0027] The wind speed self-adaptive control method of the DC frequency conversion gas water heater includes the following process:

[0028] 1. When there is no blockage in the standard smoke pipe and there is no wind outside, the DC blower will intelligently match during normal combustion; when the user boils the water, start to calculate the demand load P(kw)=L*(T setting-T water intake) / 14 is Constant (when the user takes a bath with water, the general demand load is constant, and the set temperature and water flow do not change). For example, when the demand load is 16.5kw, it can be inferred that the work at this time is 6 segments, and the proportional valve is opened. The degree is between PH and PL, and the output speed of the fan is calculated from the proportional relationship as 2000+(16.5-10) / (23-10)*(3000-2000)=2500r / min. When the demand load changes, the fan speed changes accordingly;

[0029] 2. When the smoke pipe is blocked or there is wind outside:

[0030] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com