Interlocking device and multi-order nested high-precision self-adaptive sensor applying interlocking device

A technology of interlocking device and sensor, which is applied to fluid pressure measurement, measuring device, instrument, etc. using optical methods, can solve the problem of sensor explosion range, lack of sufficient understanding of the distribution and variation of seabed sediment intensity, and lack of deep-sea environment. and other problems to achieve the effect of self-adjustment of range and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

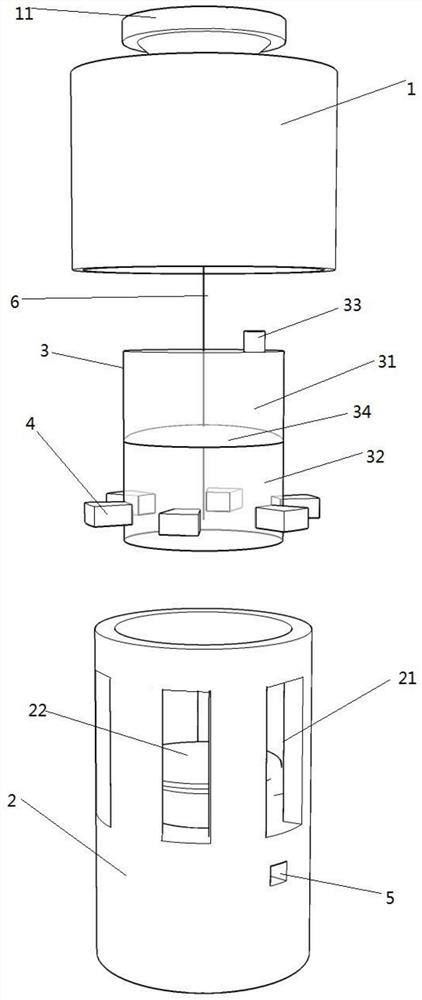

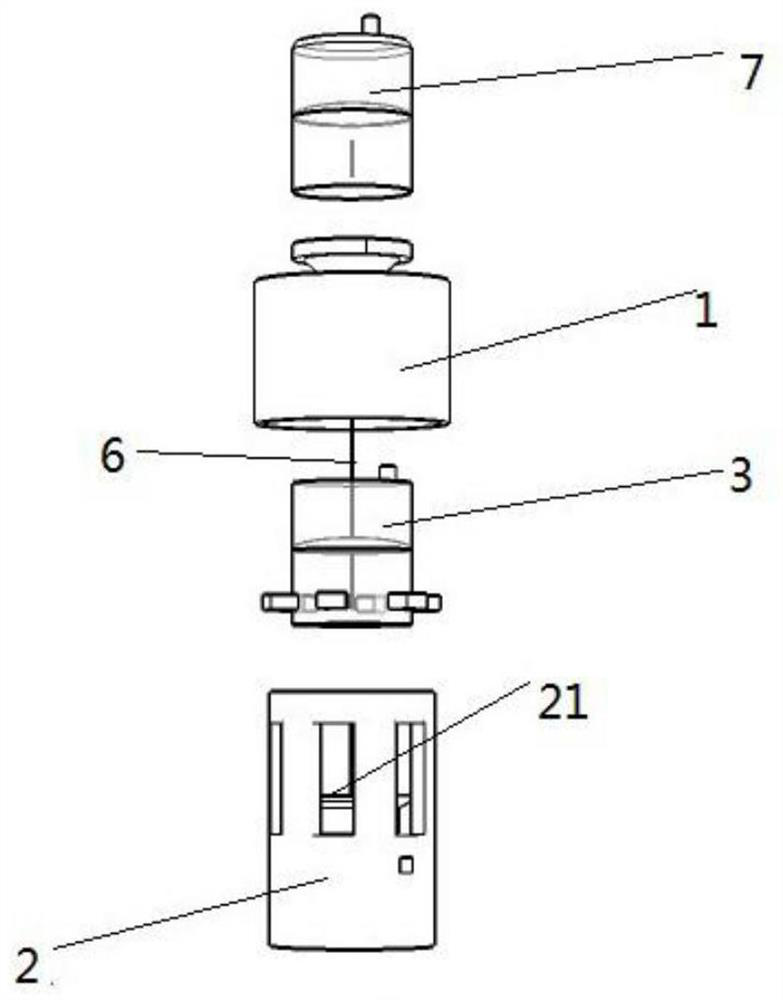

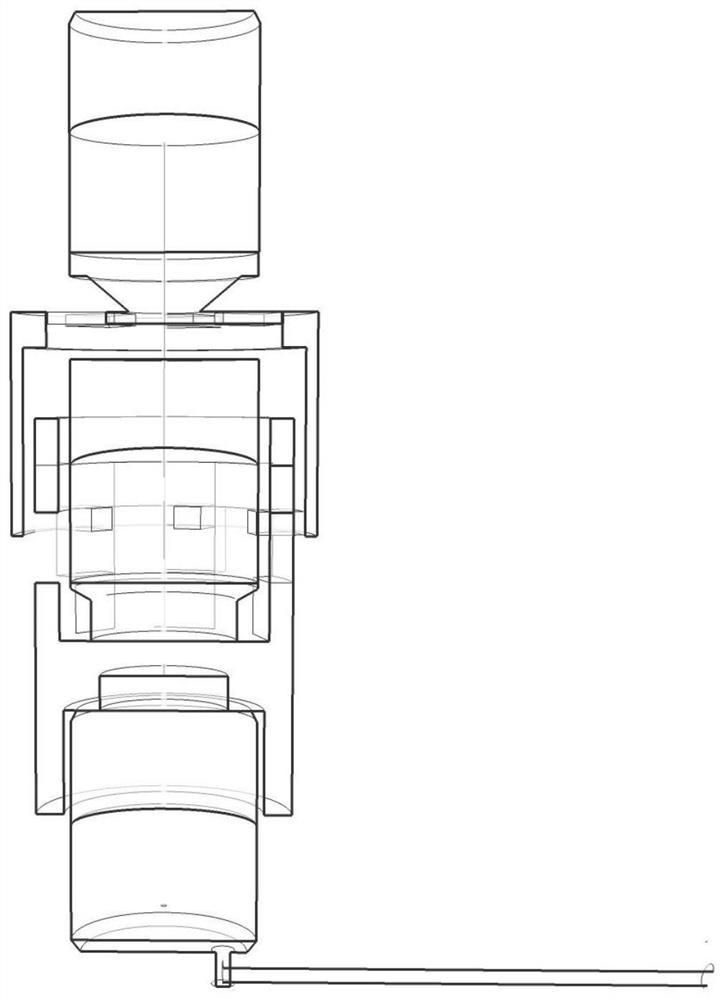

[0025] Embodiment 1, a kind of interlocking device, such as figure 1 As shown, it includes a positive lock connection sleeve 2 and a reverse lock connection sleeve 1. The reverse lock connection sleeve 1 is sleeved above the positive lock connection sleeve 2, and an accommodation space is formed between the positive lock connection sleeve 2 and the reverse lock connection sleeve 1. The positive lock connecting sleeve 2 is provided with a first piston column 22, the top of the anti-lock connecting sleeve 1 is provided with a second piston column 11, and a vertical chute 21 is also provided along the outer wall of the positive lock connecting sleeve 2. , and on the inner wall of the anti-lock connection sleeve, along its circumferential direction, a protruding post 4 matching the vertical chute is provided, and the protruding post 4 can slide up and down along the vertical chute 21.

Embodiment 2

[0026] Embodiment 2, a multi-level nested high-precision adaptive sensor with the interlock device described in Embodiment 1, continue to refer to figure 1 , including n differential pressure sensors connected sequentially from bottom to top, that is, the first-stage differential pressure sensor, the second-stage differential pressure sensor, ..., the n-1th stage differential pressure sensor and the n-th stage differential pressure sensor, wherein, n≥2, the n differential pressure sensors all use differential pressure fiber grating sensors, and the measuring range of the n differential pressure sensors increases step by step from bottom to top, for example, the measuring range of the first differential pressure sensor is 1-10Pa, the second The range of the first-order differential pressure sensor is 10-100Pa, the range of the third-order differential pressure sensor is 100Pa-1Kpa, the range of the fourth-order differential pressure sensor is 1KPa-10Kpa, and the range of the fif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com