Breaker switching-on and switching-off coil protection type resettable fuse, manufacturing process and application of breaker switching-on and switching-off coil protection type resettable fuse

A self-recovery fuse, opening and closing coil technology, applied in the direction of fuse manufacturing, protection switch operation/release mechanism, protection switch, etc., can solve the problems of increasing power outages, power outages, manpower and material replacement, etc., to achieve stable opening and closing, The effect of reducing risk, reducing the number and area of power outages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

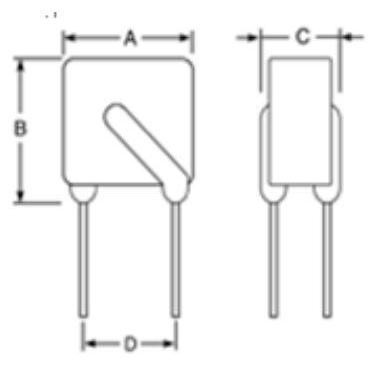

[0015] Embodiment 1: as figure 2 As shown, in the first aspect, a circuit breaker opening and closing coil protection type self-recovery fuse, including lead wires, packaging shells, and internal base materials; epoxy powder. The internal base material includes: 10% of solder, 30% of copper foil, and 60% of base material.

[0016] figure 2 Among them, the length A of the fuse: 12mm (maximum value); width B: 17mm (maximum value); thickness C: 4.5mm (maximum value); the distance between the two pins D5.1mm (typical value);

[0017] Further, the internal base material is made of a high molecular weight organic polymer under the conditions of high pressure, high temperature, and vulcanization reaction, after being mixed with conductive particle materials, and then processed through a manufacturing process.

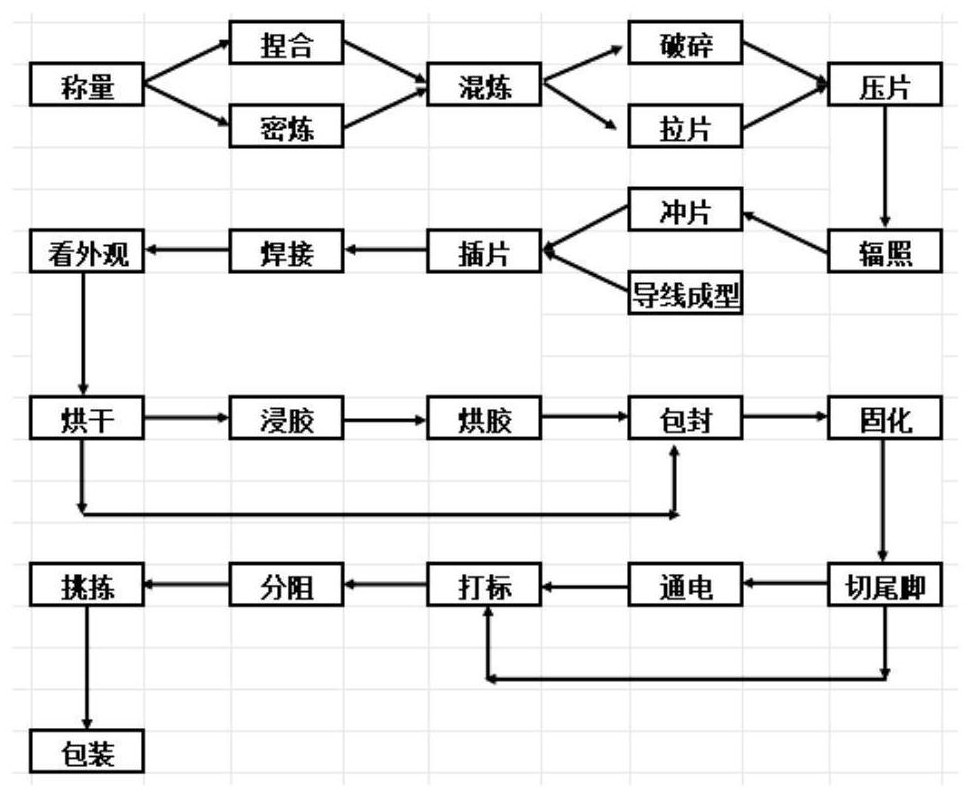

[0018] Second aspect, such as figure 1 Shown, a circuit breaker opening and closing coil protection type internal base material manufacturing process, the manufacturing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com