Servo motor

A servo motor and drive motor technology, applied in the field of servo motors, can solve problems such as large motor noise, and achieve the effects of protecting the motor, running stably, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

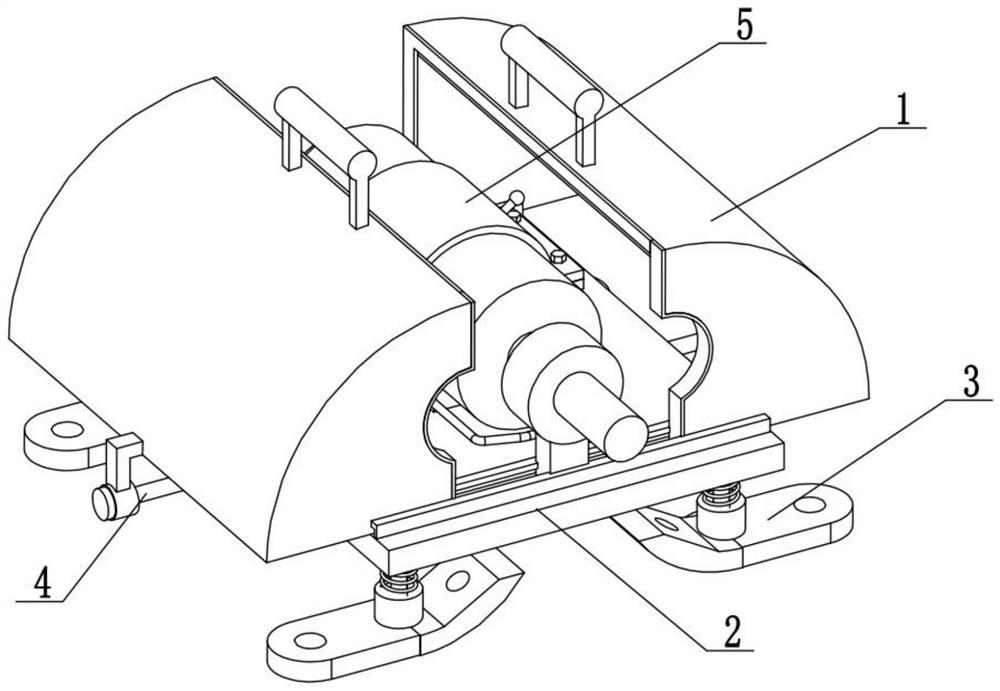

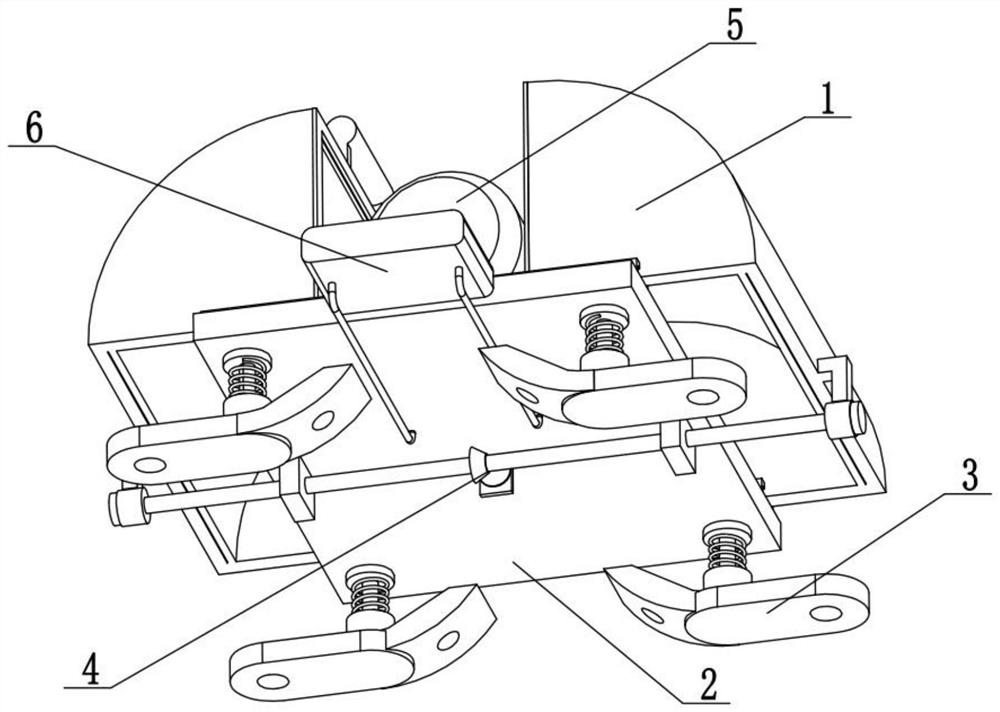

[0027] Combine below Figure 1-8 Describe this embodiment, the present invention relates to the technical field of servo motors, more specifically a servo motor, including a noise reduction component 1, a sliding limit component 2, a shock absorbing and fixing component 3, an opening and closing drive component 4, and a motor installation component 5 and a water-cooling heat dissipation assembly 6, the water-cooling heat dissipation assembly 6 is connected to the sliding limit assembly 2 and the motor installation assembly 5, the motor installation assembly 5 is connected to the slide limit assembly 2, and the slide limit assembly 2 is connected to four shock absorbers The fixed component 3, the opening and closing drive component 4 are connected to the sliding limit component 2, the two noise reduction components 1 are connected to the sliding limit component 2, and the two noise reduction components 1 are screwed with the sliding limit component 2, Both noise reduction compo...

specific Embodiment approach 2

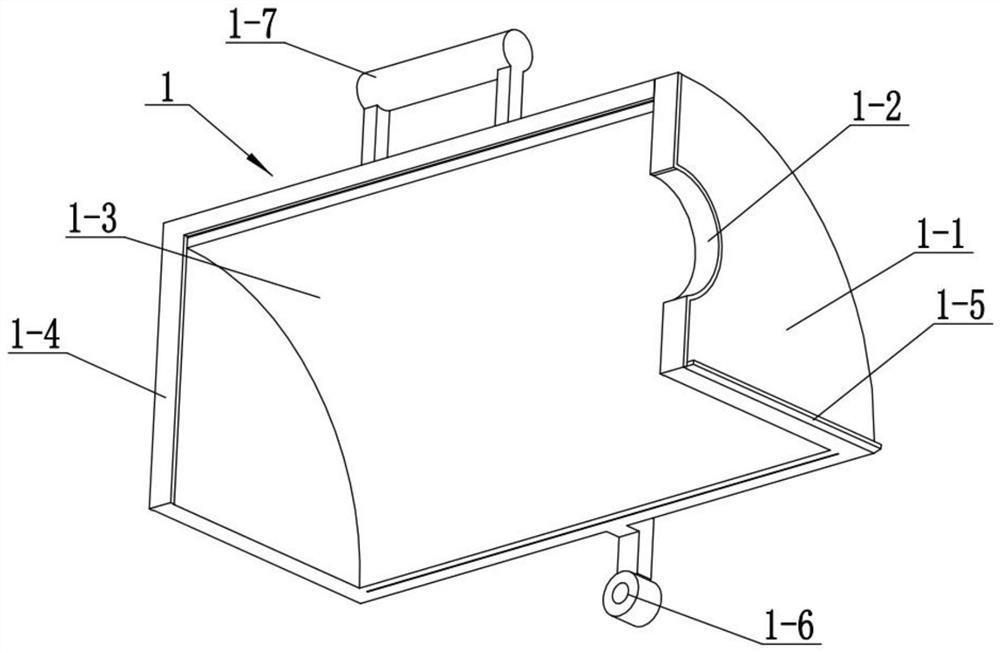

[0030] Combine below Figure 1-8 Describe this embodiment, this embodiment will further explain Embodiment 1, the noise reduction assembly 1 includes a sound-absorbing cover 1-1, a semicircular hole 1-2, a sound-absorbing sponge 1-3, a soft rubber pad 1-4, T type slide plate 1-5, threaded bushing 1-6 and lifting handle 1-7, the lifting handle 1-7 is fixedly connected on the sound-absorbing cover 1-1, and the front end of the sound-absorbing cover 1-1 is provided with a semicircular hole 1-2, The two T-shaped slides 1-5 are fixedly connected to the bottom of the sound-absorbing cover 1-1, the inner wall of the sound-absorbing cover 1-1 is fixedly connected with a sound-absorbing sponge 1-3, and the threaded bushing 1-6 is fixedly connected to the sound-absorbing cover 1-1. 1. At the bottom, the sound-absorbing cover 1-1 and the semicircular hole 1-2 are all fixedly connected with a soft rubber pad 1-4.

[0031] The sound-absorbing sponge 1-3 has unique sound-absorbing, heat-in...

specific Embodiment approach 3

[0033] Combine below Figure 1-8 Describe this embodiment, this embodiment will further explain the second embodiment, the sliding limit assembly 2 includes a sliding platform 2-1, a ball bearing 2-2 and a T-shaped slide 2-3, two T-shaped slides The track 2-3 is fixedly connected to the sliding platform 2-1, the ball bearing 2-2 is fixedly connected to the T-shaped slideway 2-3 at the front end, and the two T-shaped slides 1-5 are respectively slidably connected to the two T-shaped slideways. In the type slideway 2-3, two sound-absorbing covers 1-1 are arranged symmetrically, and the bottom surfaces of the two sound-absorbing covers 1-1 are in contact with the upper end surface of the sliding platform 2-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com