Cavitation jet intelligent nozzle and underwater cleaning robot

An intelligent, nozzle technology, applied in the direction of spraying device, spraying device, etc., can solve the problems of unable to obtain cleaning effect, affecting cleaning efficiency, unable to obtain optimization, etc., to achieve the benefits of underwater operation, improve cleaning effect, improve automation and intelligence effect of level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

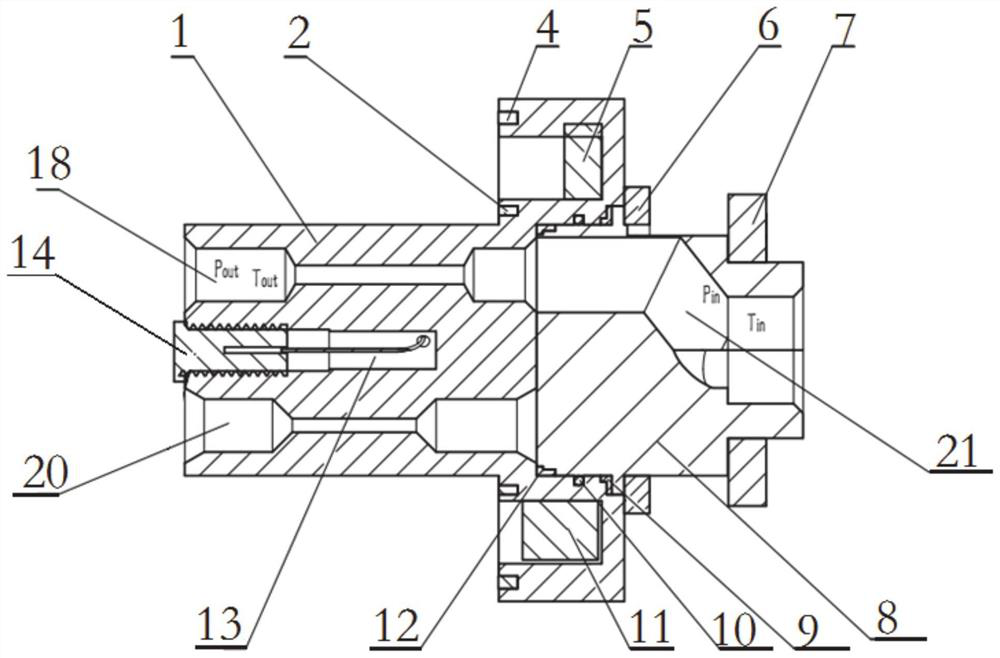

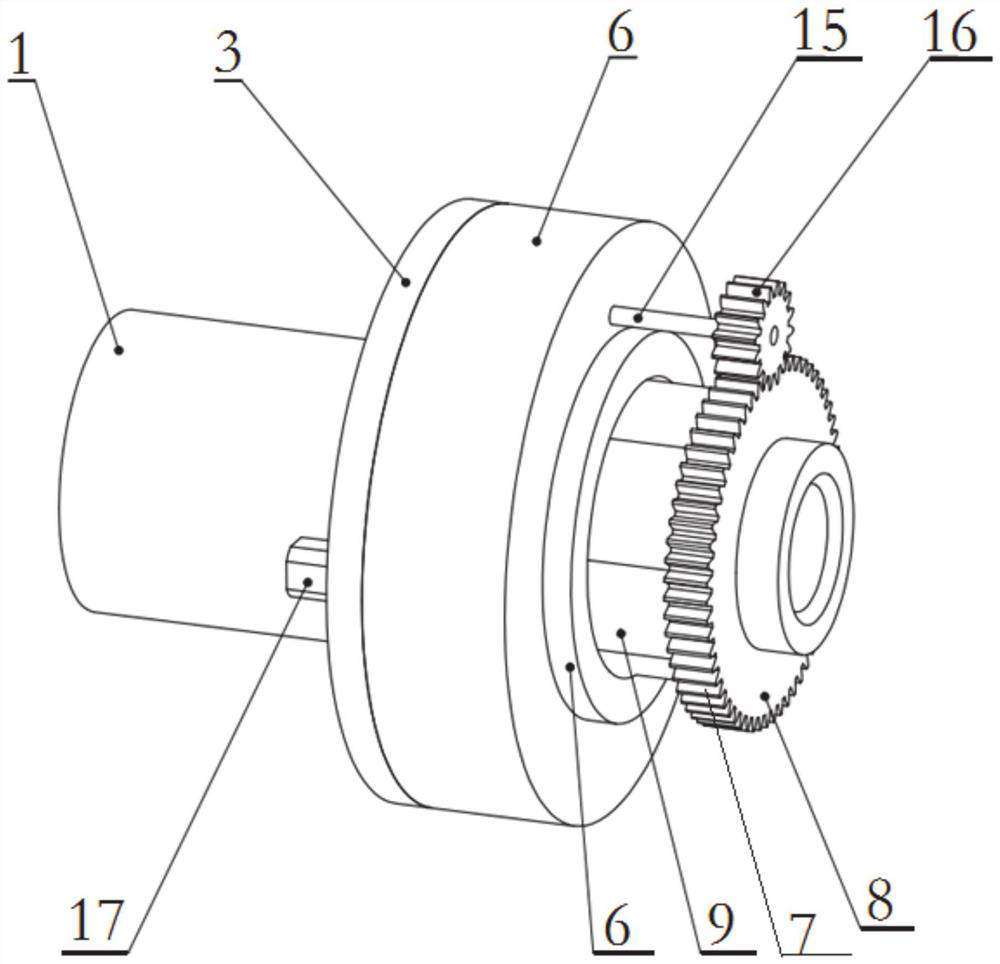

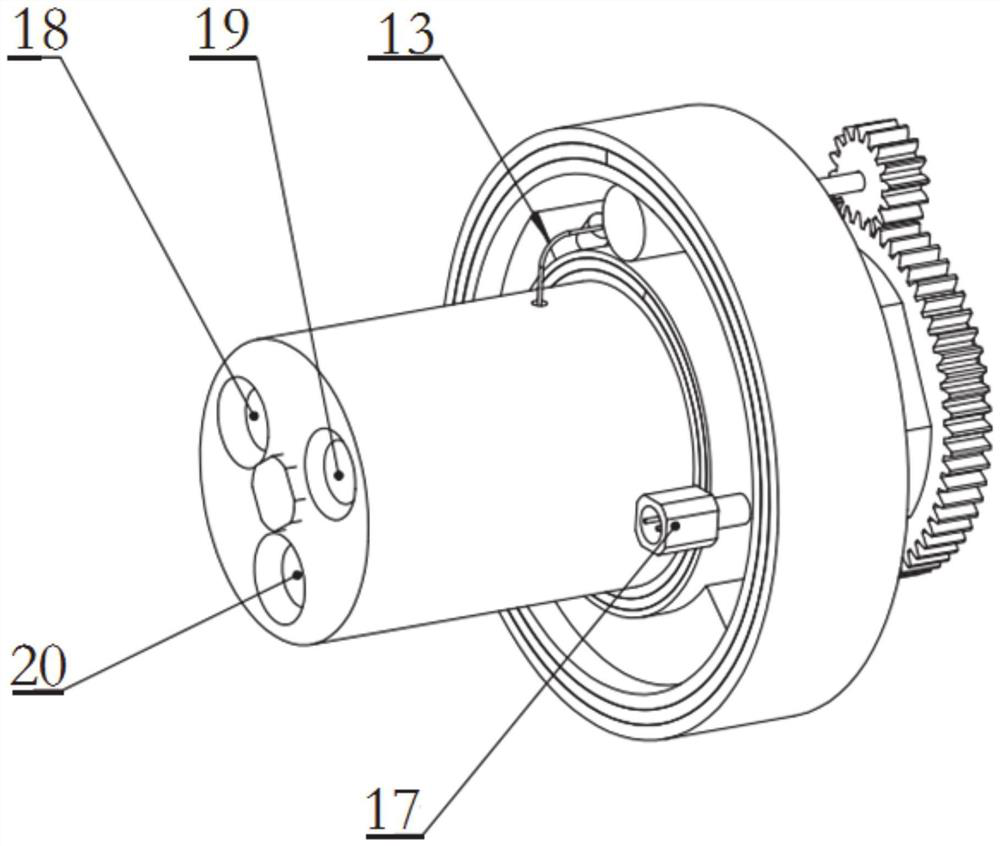

[0029] In a typical embodiment of the present invention, such as Figure 1 to Figure 5 As shown, this embodiment discloses a cavitation jet intelligent nozzle. The intelligent nozzle is composed of multi-component assembly. The main structure of the nozzle is mainly composed of the nozzle body 1 and the shaft tube 8. The contact between the nozzle body 1 and the shaft tube 8 The nozzle 1 is provided with 3 outlets, which are respectively the first outlet 18, the second outlet 19 and the third outlet 20, and a depth sensor 14 for measuring underwater depth, pressure and Temperature, also be provided with an annular groove 22, two seal ring grooves, be the first seal ring groove 25 and the second seal ring groove 26 respectively. In the annular groove 22 of the nozzle body, there are control power supply, control board and motor system, and a sealing cover 3 is provided on the left side of the annular groove 22, the purpose is to protect the control system in the groove and prev...

Embodiment 2

[0043] In a typical implementation of the present invention, this embodiment also discloses an underwater cleaning robot, including a cavitation jet intelligent nozzle as described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com