Ore screening machine for mines

A screening machine and ore technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of single filter function, low screening accuracy, inconvenient ore removal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

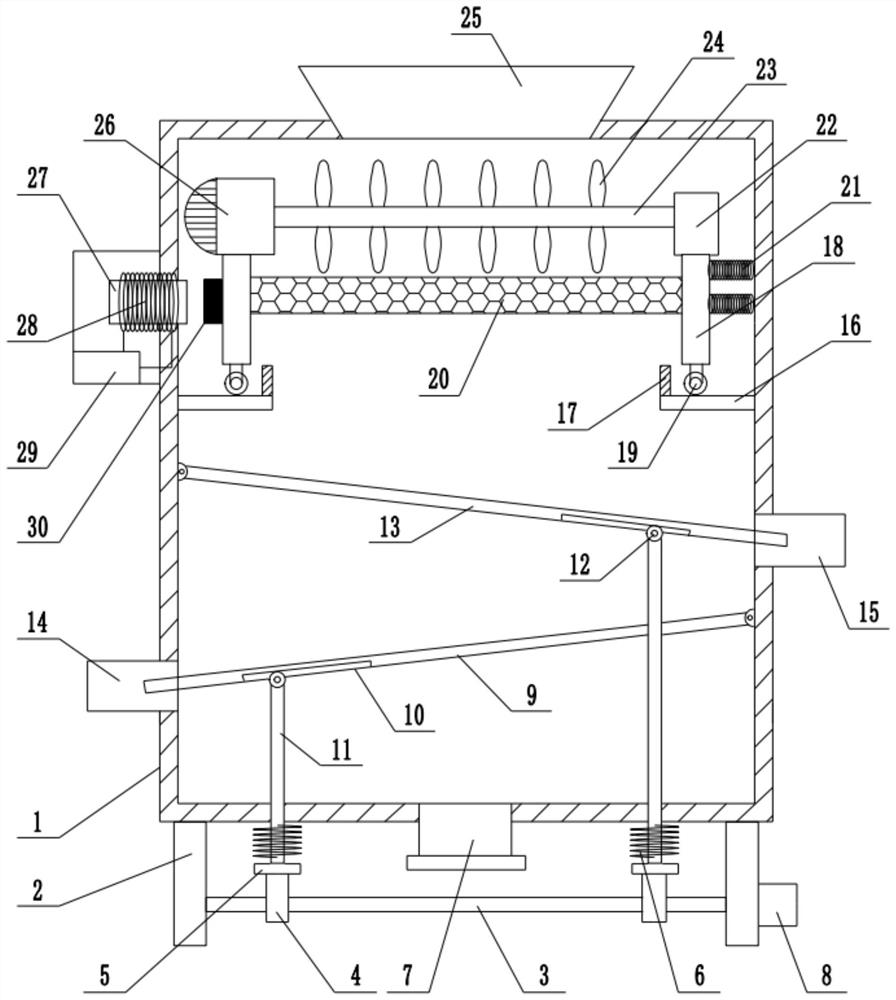

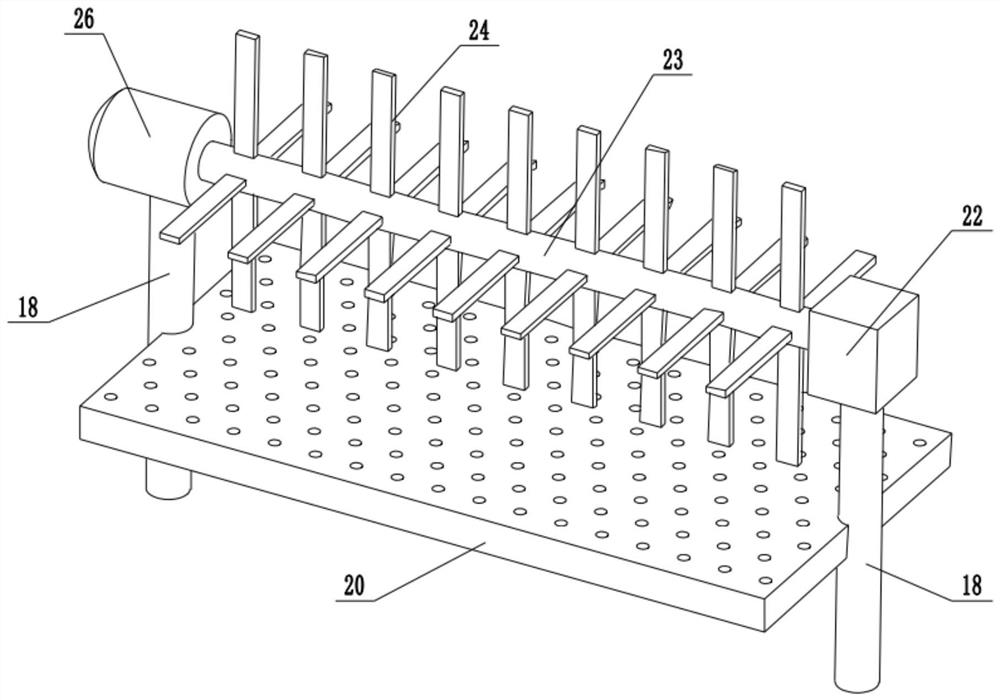

[0030] refer to Figure 1~3 , in the embodiment of the present invention, a mine ore screening machine includes a screening box 1, a feed hopper 25 is installed in the middle of the top of the screening box 1, and is used to realize the preliminary introduction of mine ore, and a bottom screen is installed in the middle of the lower end of the screening box 1 Pipe 7 is used to realize the derivation of stones with the smallest particle size. A slide rail 16 is installed on the upper end of the inner wall of the screening box 1, and a pulley 19 is slidably arranged on the slide rail 16. A support column 18 is installed on the upper end of the pulley 19, and a support column 18 is installed on the left side. The upper end is equipped with a pulverizing motor 26, which is used to drive the pulverizing shaft 23 to rotate. The output shaft of the pulverizing motor 26 is connected with the pulverizing shaft 23, and a plurality of pulverizing leaves 24 are installed on the outside of ...

Embodiment 2

[0032]In another embodiment of the present invention, a screening box 1 is included, a feed hopper 25 is installed in the middle of the top of the screening box 1, a bottom screen pipe 7 is installed in the middle of the lower end of the screening box 1, and a slide rail 16 is installed at the upper end of the inner wall of the screening box 1. A pulley 19 is slidably arranged on the slide rail 16, a supporting column 18 is installed on the upper end of the pulley 19, a pulverizing motor 26 is installed on the upper end of the left supporting column 18, and the output shaft of the pulverizing motor 26 is connected with a pulverizing shaft 23, and a plurality of pulverizing shafts 23 are installed on the outside Grinding leaves 24, the other end of the crushing shaft 23 is rotated and arranged on the fixed block 22 fixed on the right side support column 18, and a filter plate 20 is installed between the middle of the support column 18, and the filter plate 20 is provided with sev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com