Construction waste recycling production line

A technology for recycling and processing construction waste, which is applied in construction waste recycling, grain processing, recycling technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following is attached Figure 1-10 The application is described in further detail.

[0043] The embodiment of the present application discloses a construction waste recycling and processing production line.

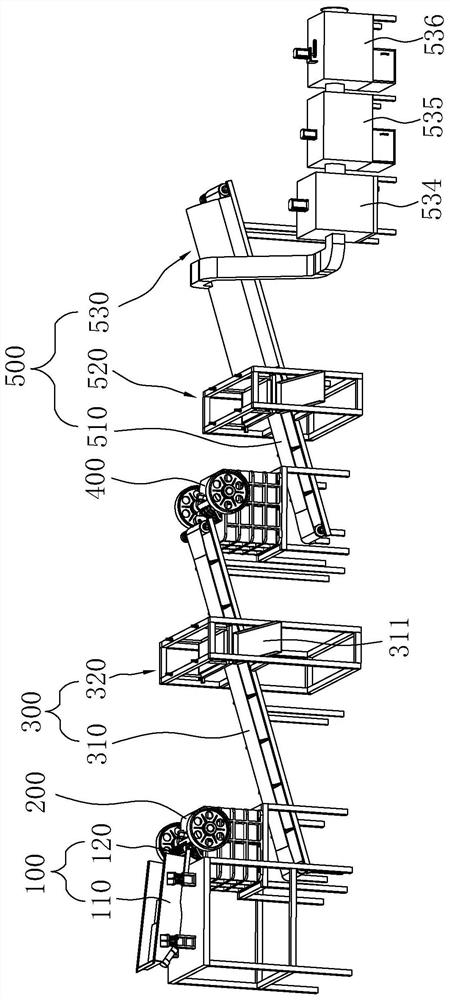

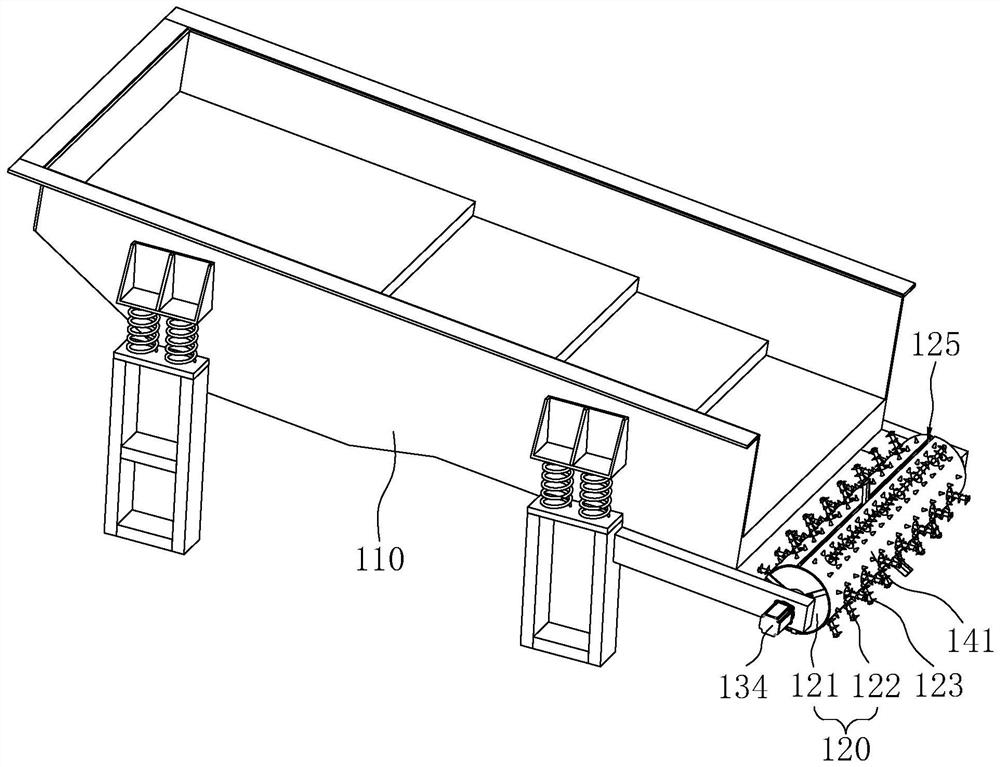

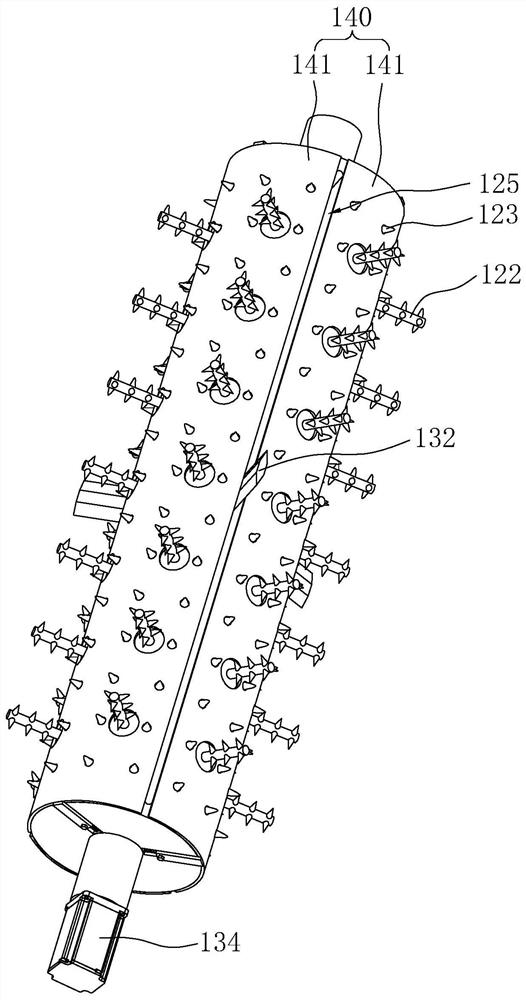

[0044] refer to figure 1 , a production line for recycling and processing construction waste includes a feeding device 100, a primary crushing device, a primary conveying device 300, a secondary crushing device, and a secondary conveying device 500 arranged in sequence, and the feeding device 100 is used to transport construction waste And make the rags in the construction waste leak out of the construction waste; the primary crushing device is used for primary crushing of the construction waste; the primary conveying device 300 is used for transporting the construction waste and screening the iron substances in the construction waste; The secondary crushing device is used for final crushing of construction waste to obtain construction waste of corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com