Rust removal device for mechanical production

A technology for machinery and rotating electrical machines, applied in the field of rust removal devices for mechanical production, can solve the problems of inability to mix rust removal liquid and rusted metal parts, difficult to popularize and apply, and poor rust removal effect, so as to improve the rust removal effect and ensure Rust removal effect, good contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

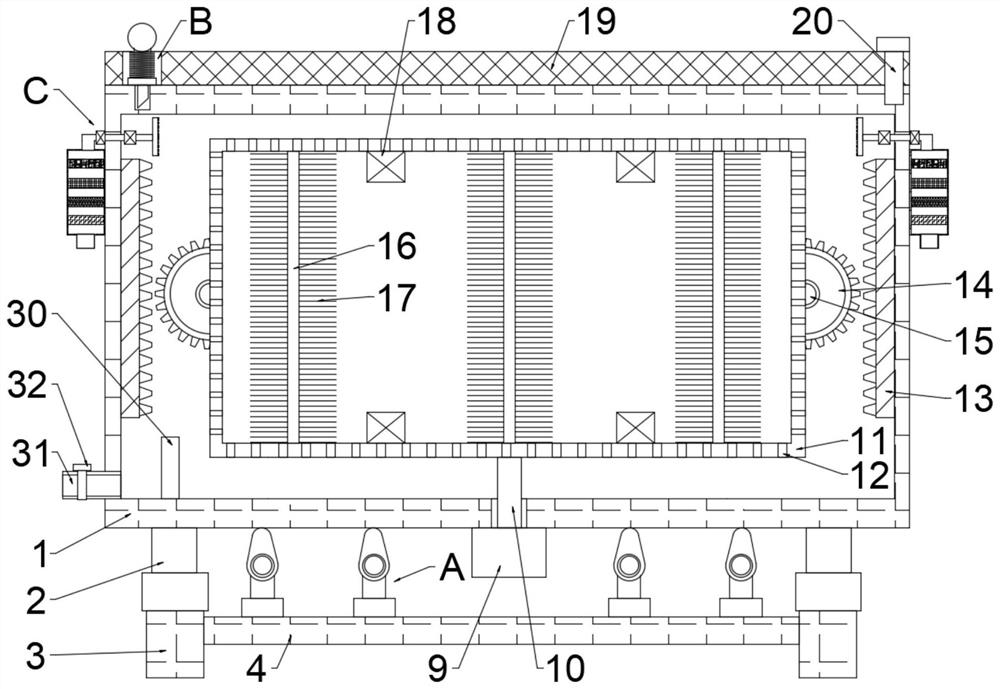

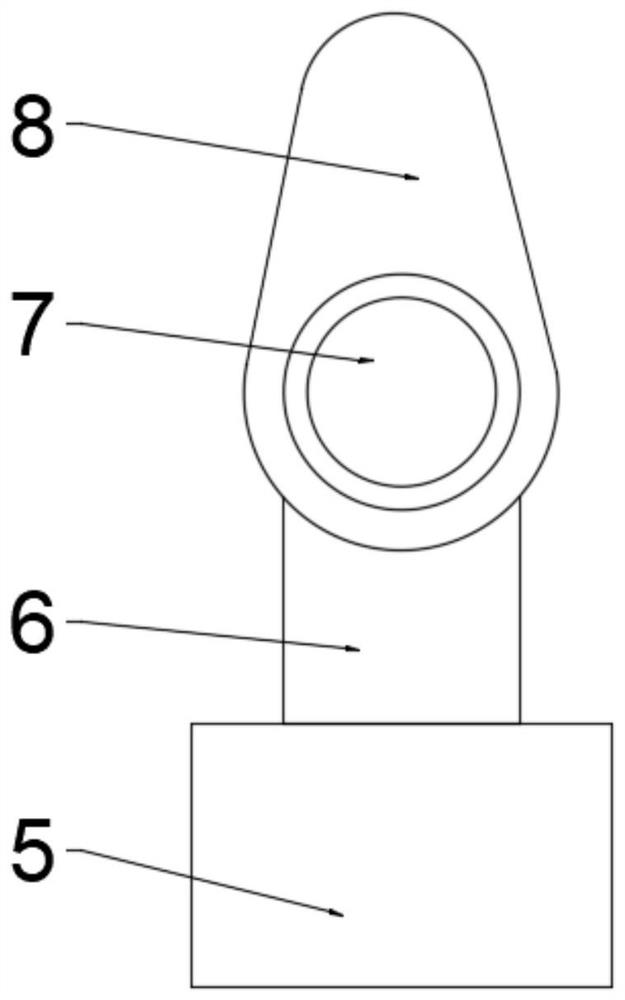

[0030] see Figure 1 to Figure 5 , a rust removal device for mechanical production, including a base 1, a device box 41 is arranged on the base 1, a cleaning cylinder 11 is arranged in the device box 41, and a telescopic rod 2 is symmetrically arranged under the base 1 One end of the telescopic rod 2 away from the base 1 is fixedly connected to the support leg 3, the support leg 3 is provided with a crossbeam 4, the crossbeam 4 is fixedly connected to the support leg 3, and the crossbeam 4 is provided with several motors 5, so There are at least four motors 5, the motors 5 are evenly distributed on the beam 4, the output end of the motor 5 is fixedly connected to the turbine 6, the turbine 6 is connected to the worm 7, and the end of the worm 7 away from the turbine 6 is connected to the cam 8 , the cam 8 is movably connected to the device box 41, the cleaning cylinder 11 is provided with a through hole 12, the through hole 12 runs through the cleaning cylinder 11, the through...

Embodiment 2

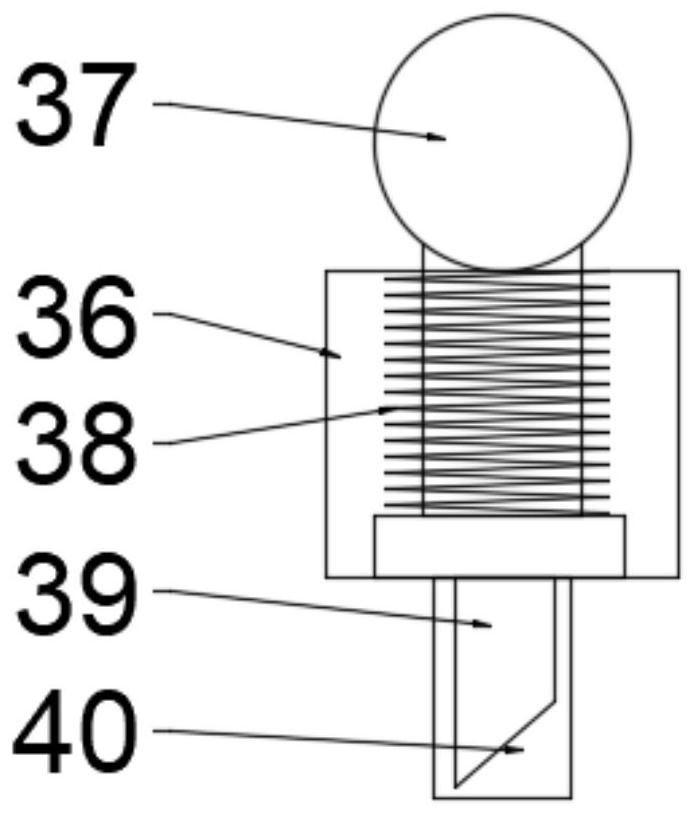

[0037] see Figure 1 to Figure 6 , a rust removal device for mechanical production, including a base 1, and also includes an upper chute 33, a slide bar 34 and a lower chute 35, the base 1 is provided with a device box 41, and the device box 41 is provided with Cleaning cylinder 11, a telescopic rod 2 is symmetrically arranged under the base 1, and one end of the telescopic rod 2 away from the base 1 is fixedly connected to a support leg 3, and a crossbeam 4 is arranged on the support leg 3, and the crossbeam 4 is fixedly connected to the support leg 3. Several motors 5 are arranged on the beam 4, at least four motors 5 are arranged, and the motors 5 are evenly distributed on the beam 4. The output ends of the motors 5 are fixedly connected to the turbine 6, and the turbine 6 Connect the worm 7, the end of the worm 7 away from the turbine 6 is connected to the cam 8, the cam 8 is movably connected to the device box 41, the cleaning cylinder 11 is provided with a through hole 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com