Rice cake slicing and forming equipment for food processing

A food processing and forming equipment technology, applied in metal processing and other directions, can solve the problems of uneven cutting, unsafe, time-consuming and labor-intensive, etc., and achieve the effect of uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

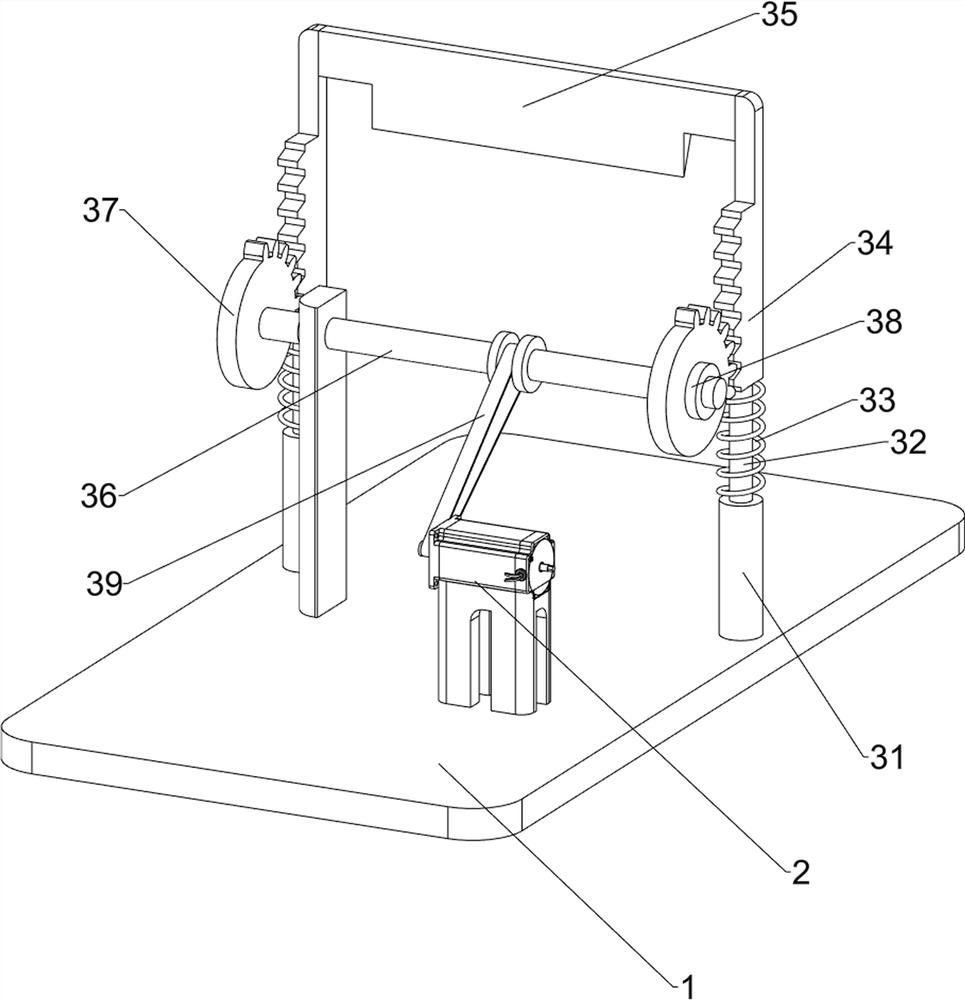

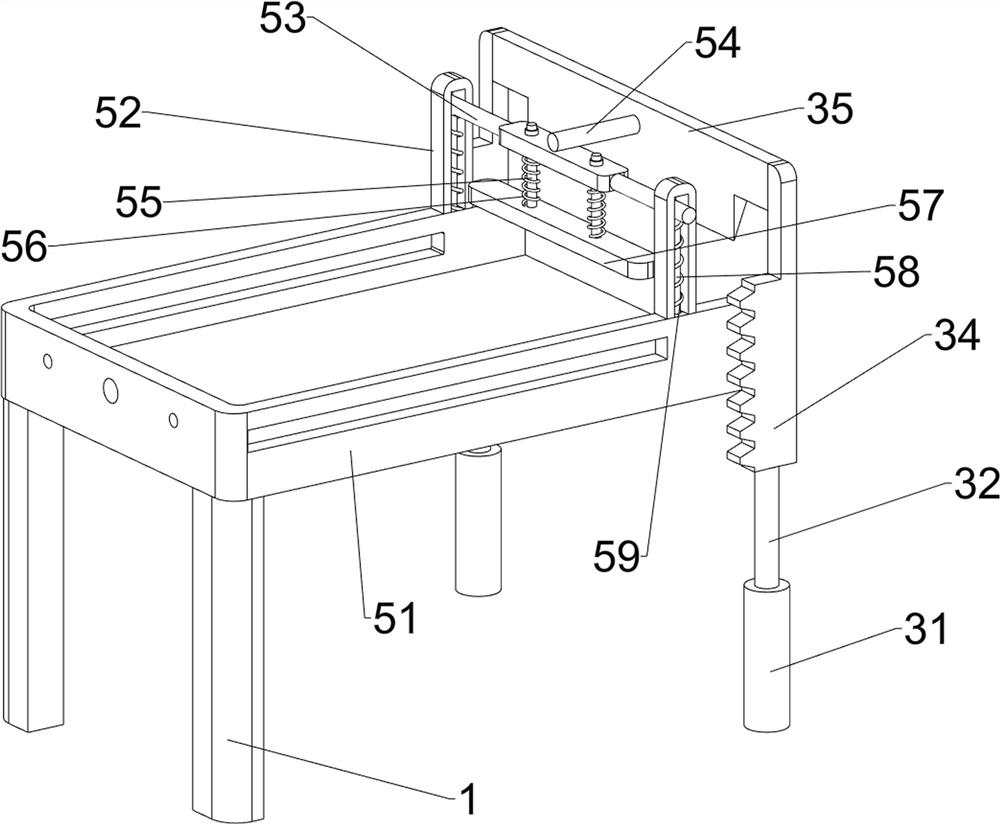

[0062] A kind of rice cake slice forming equipment for food processing, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 As shown, it includes a base plate 1, a servo motor 2, a slicing mechanism 3, a shaking mechanism 4 and a pressing mechanism 5. The upper left part of the base plate 1 is equipped with a servo motor 2, and the upper middle part of the base plate 1 is provided with a slicing mechanism 3. The slicing mechanism 3 and the The output shaft of the servo motor 2 is connected, the base plate 1 is provided with a shaking mechanism 4, the shaking mechanism 4 cooperates with the slicing mechanism 3, the base plate 1 is provided with a pressing mechanism 5, and the pressing mechanism 5 cooperates with the slicing mechanism 3 and the shaking mechanism 4.

[0063]Manual cutting is time-consuming, laborious, uneven and unsafe. This equipment can cut automatically, saving time and effort, cutting evenly and safely. First, people put a large ...

Embodiment 2

[0065] On the basis of Example 1, such as image 3 , Figure 4 , Figure 5 with Image 6 As shown, the slicing mechanism 3 includes a fixed sleeve 31, a first slide bar 32, a first spring 33, a rack 34, a cutter 35, a first rotating shaft 36, a missing gear 37, a fixed pin 38 and a transmission assembly 39. On the bottom plate 1 The front and rear sides of the middle part are all provided with fixed sleeves 31, and the inner sides of the upper parts of the two fixed sleeves 31 are all slidably provided with first slide bars 32, and the tops of the two first slide bars 32 are provided with racks 34, and the two first slide bars 32 is wound with a first spring 33, the top of the first spring 33 is connected with the rack 34, the bottom of the first spring 33 is connected with the fixed sleeve 31, the top of the rack 34 on the front and rear sides is connected with a cutter 35, and the cutter 35 is connected with the compression Mechanism 5 cooperates, and base plate 1 middle ...

Embodiment 3

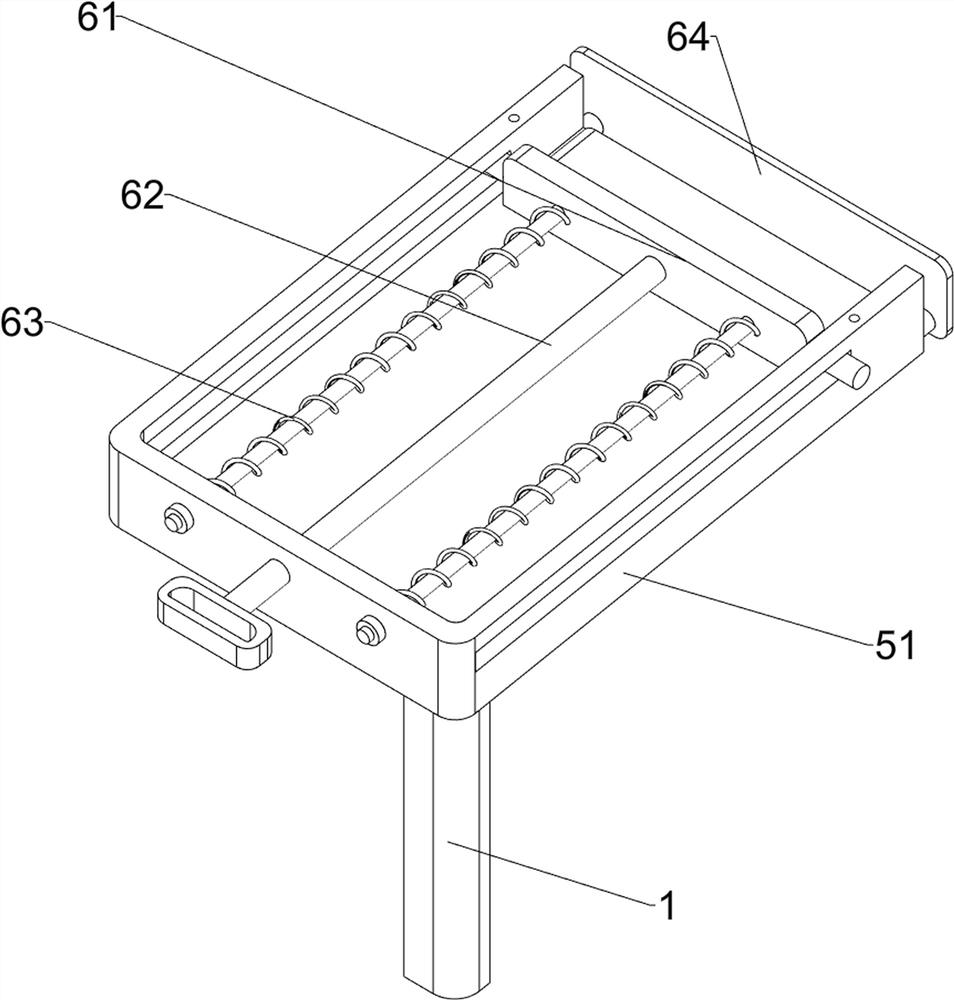

[0072] On the basis of Example 2, such as figure 1 , figure 2 with Image 6 Shown, also comprise push clamp mechanism 6, be provided with push clamp mechanism 6 on the material box 51, push clamp mechanism 6 includes push plate 61, pull rod 62, elastic member 63 and baffle plate 64, the front and back of material box 51 interior Both sides are slidably connected with a push plate 61, the push plate 61 is in contact with the inner bottom side of the material storage box 51, and the middle part on the left side of the push plate 61 is connected with the material storage box 51 with a pull rod 62, and the pull rod 62 is slidably connected with the material storage box 51, The front and rear sides of the left part of the push plate 61 are connected with the material box 51 with an elastic member 63 , and the right side of the material box 51 is provided with a baffle plate 64 , and the push plate 61 cooperates with the baffle plate 64 .

[0073] In the initial state, the push p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com