Plastic film machine

A technology of plastic film and barrel, which is applied in the field of plastic film production, and can solve the problems of incomplete fracture of the film body and uneven thickness of the film body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

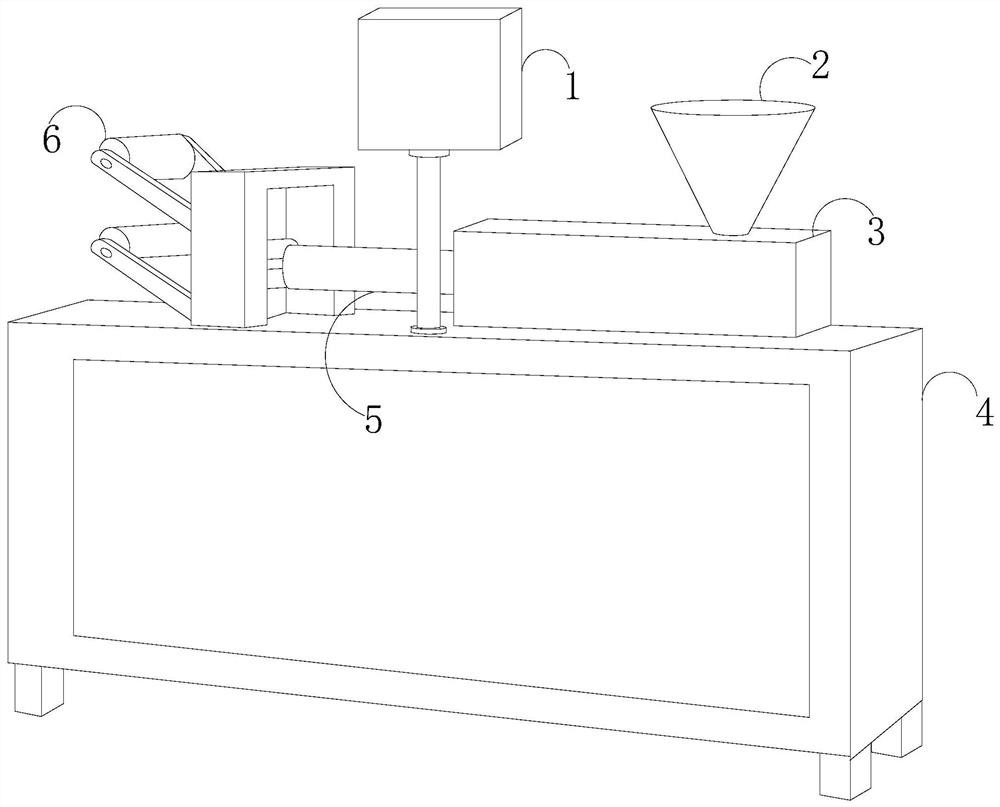

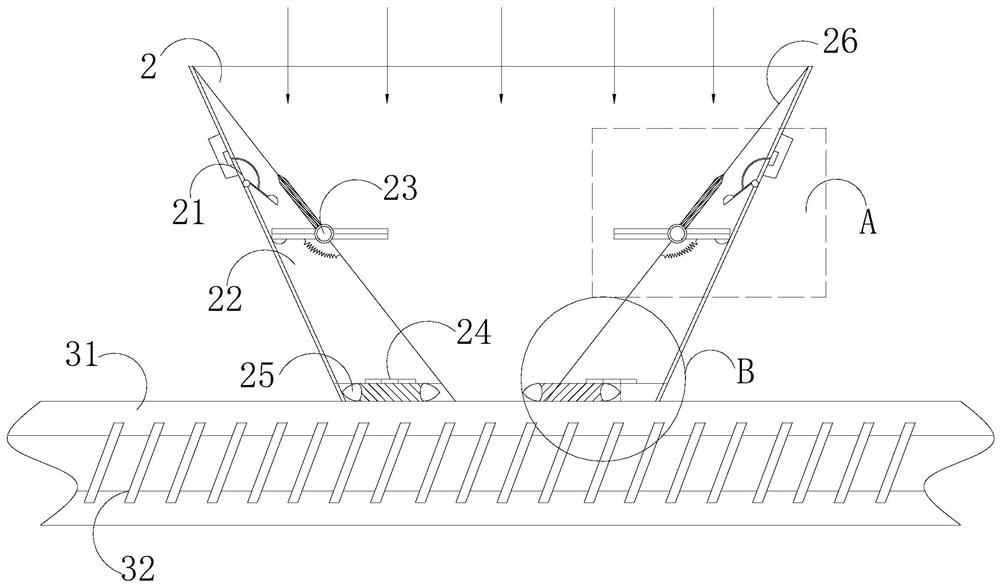

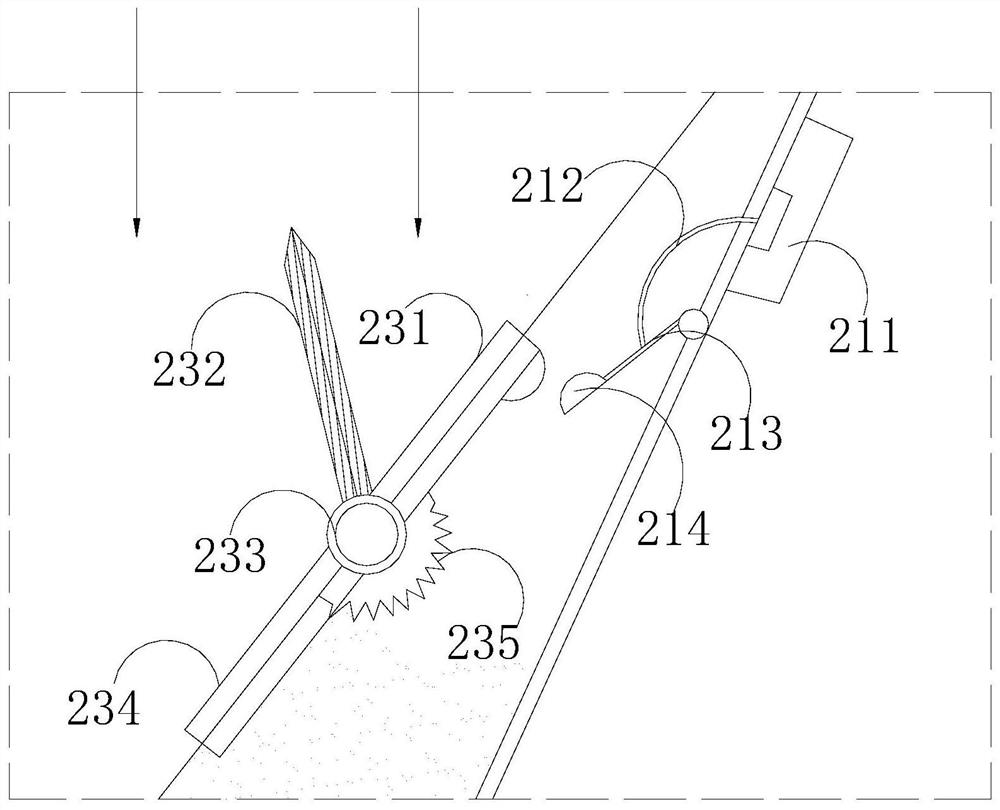

[0031] Such as Figure 1-Figure 8As shown, the present invention provides a kind of plastic film machine, and its structure comprises control panel 1, feed funnel 2, barrel 3, main frame 4, extruding end 5, guide film roller 6, and material is installed on the main frame 4 The barrel 3 and the control panel 1, the barrel 3 is provided with a feed funnel 2, the barrel 3 cooperates with the film guide roller 6 through the extrusion end 5, and the inside of the feed funnel 2 is provided with a reminder device 21 , material storage liner 22, rotating pendant 23, discharge port 24, movable blocking member 25, inclined plate 26, described material storage liner 22 is provided with reminding device 21 and discharge port 24, and described discharge port 24 and The movable blocking member 25 cooperates, and the swash plate 26 is equipped with a rotating rocker 23, one end of the rotating rocker 23 fits in the feeding cavity of the feeding funnel 23, and the other end fits inside the st...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap