Method for eliminating submarine cable obstacles by submarine cable robot

An obstacle, underwater robot technology, applied in cable installation, cable laying equipment, ground cable installation, etc., can solve the problem of low work efficiency, waste of manpower and material resources, and difficult operation of submarine cables for operation and maintenance operators. Check maintenance and other issues to reduce safety risks, improve efficiency, and improve the automation and intelligence of submarine cable system operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

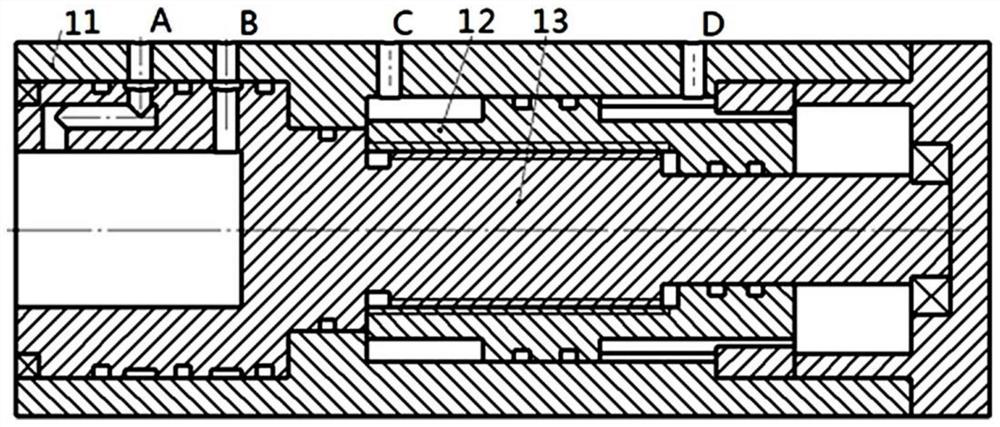

[0028] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

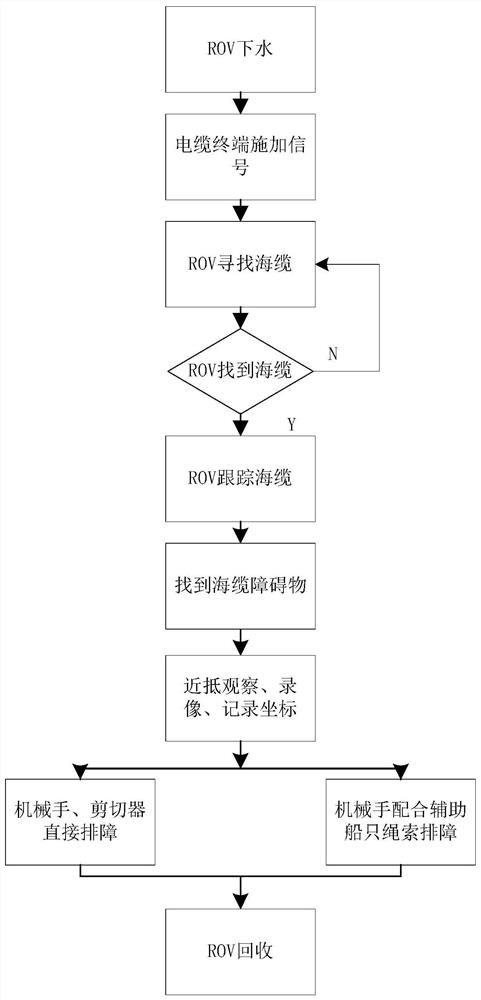

[0029] Such as figure 1 Shown, the present invention comprises the following steps:

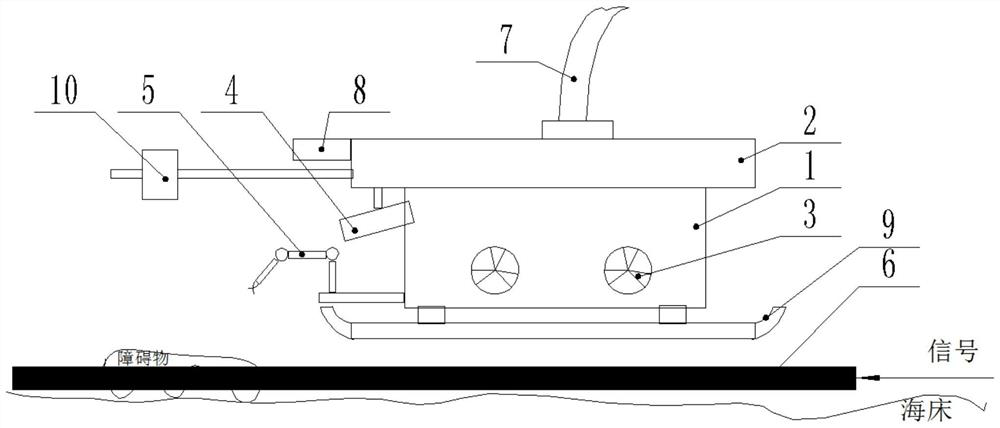

[0030] S1: The workboat is equipped with the cabled underwater robot system and arrives at the designated sea area; the cabled underwater robot system includes the cabled underwater robot and the control system; the control system and the cabled underwater robot are connected through the umbilical cable 7;

[0031] S2: After the inspection of the cabled underwater robot system is completed, the cabled underwater robot enters the water and dives slowly;

[0032] S3: According to the pre-set routing map of the submarine cable 6, combined with the navigation device of the working ship and the underwater positioning device of the cabled underwater robot, let the cabled underwater robot drive to a position near the inspection operation point;

[0033] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com