Silicon carbide ceramic re-sintering repairing process

A technology of silicon carbide ceramics and craftsmanship, which is applied in the direction of manufacturing tools, stone processing equipment, stone processing tools, etc., can solve the problems of large losses, product scrapping, and insufficient surface smoothness, and achieve the goal of avoiding potential safety hazards, saving costs, and consistent appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

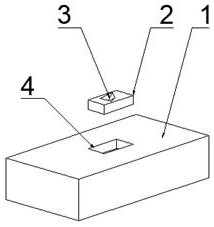

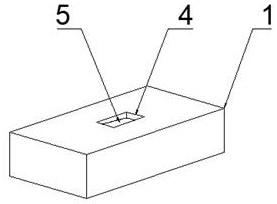

[0052]Taking the silicon carbide ceramic blank 1 with a length of 20cm, a width of 15cm, and a height of 6cm as an example, there is a crack with a length of 3cm, a width of 0.2cm, and a depth of 0.5cm on the blank, and the crack is a linear structure. The ceramic blank 1 is clamped on the workbench, take out the pneumatic file, connect the air source, use the fine texture cutter head, cut the knife at an angle perpendicular to the silicon carbide ceramic blank 1, and grind from left to right. The starting point of grinding is at the crack The left end is 0.5cm away from the end of the crack and shifted 0.2cm toward the side of the crack until the right end of the crack is 0.5cm away from the end of the crack. Because the diameter of the general pneumatic file is about 3mm, one pass from left to right is enough to close the gap where the crack is located. The position is completely covered, so the deep grinding is repeatedly deepened along the above path until the cracks are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com