Low-odor polypropylene material with ultrahigh melt index and preparation method thereof

A polypropylene, low odor technology, applied in the field of polypropylene materials with low odor and ultra-high melting index and its preparation, can solve the problems of complex process, unsatisfactory melting index, high odor, etc., and achieves simple process and high melting index. High, low odor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

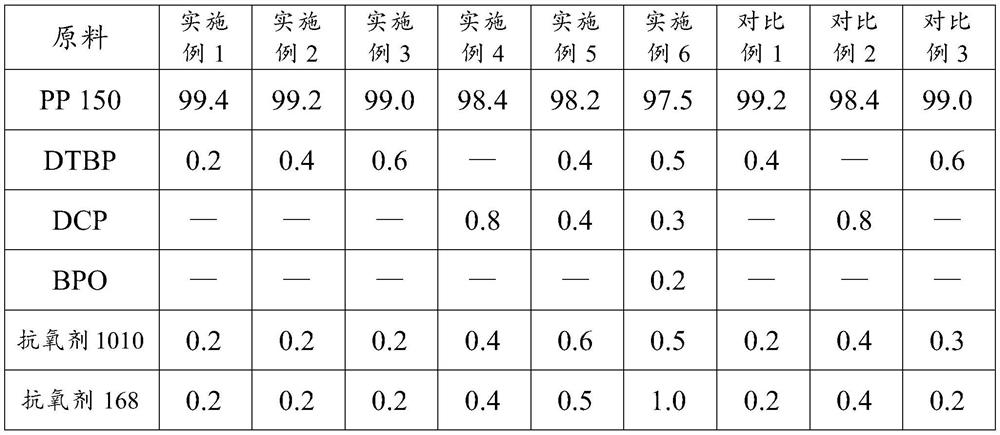

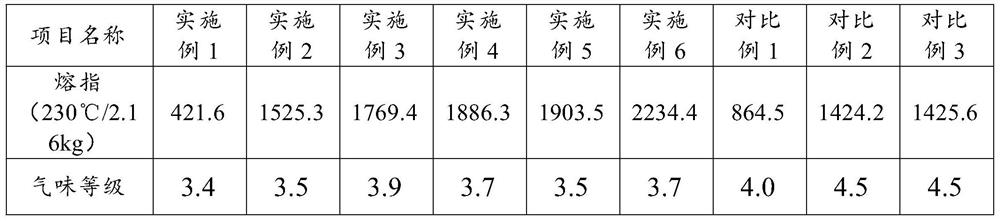

[0028] A low-odor ultra-high melting point polypropylene, the composition of the raw material formulations of Examples 1-3 is listed in Table 1. According to the formula in Table 1, the polypropylene is sent into the barrel of the twin-screw extruder from the main feed, and the peroxide initiator is quantitatively added in the third zone of the twin-screw extruder using a liquid pump , adding the antioxidant in the seventh zone by side feeding, under the set temperature, screw speed, feeding speed and other process parameters, the raw materials are melted, blended, extruded, cooled, and granulated to obtain Modified polypropylene material. The extruder used has a screw diameter of 35mm and an aspect ratio of 48. The temperatures of the 14 temperature zones from the feeding port to the machine head are 120°C, 180°C, 200°C, 200°C, 200°C, and 200°C. °C, 200°C, 200°C, 200°C, 200°C, 200°C, 200°C, 180°C, 180°C The speed of the host machine is 400 rpm, and the vacuum degree is -0.08...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt finger | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com