Long-chain branched PPH loaded beta nucleating agent master batch and preparation method thereof

A beta nucleating agent and long-chain branching technology, applied in the field of long-chain branched PPH-loaded beta nucleating agent masterbatch and its preparation, can solve the problem of poor compatibility with PP, poor heat resistance, low nucleation efficiency, etc. problem, to achieve the effect of improving toughness and ductility, and improving stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

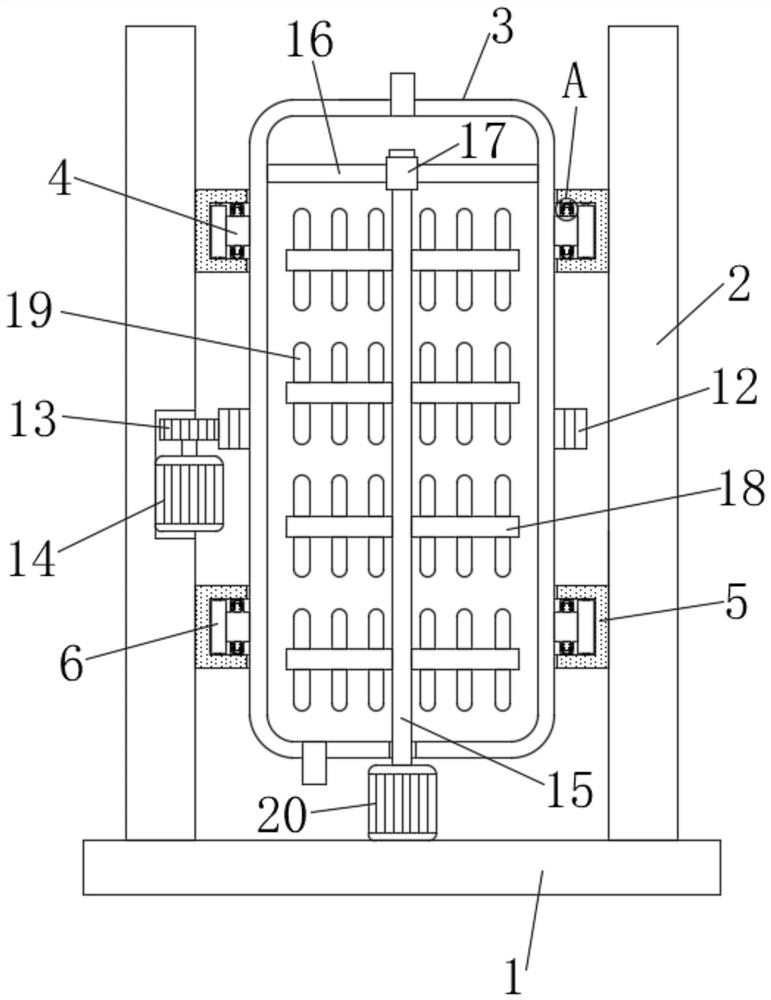

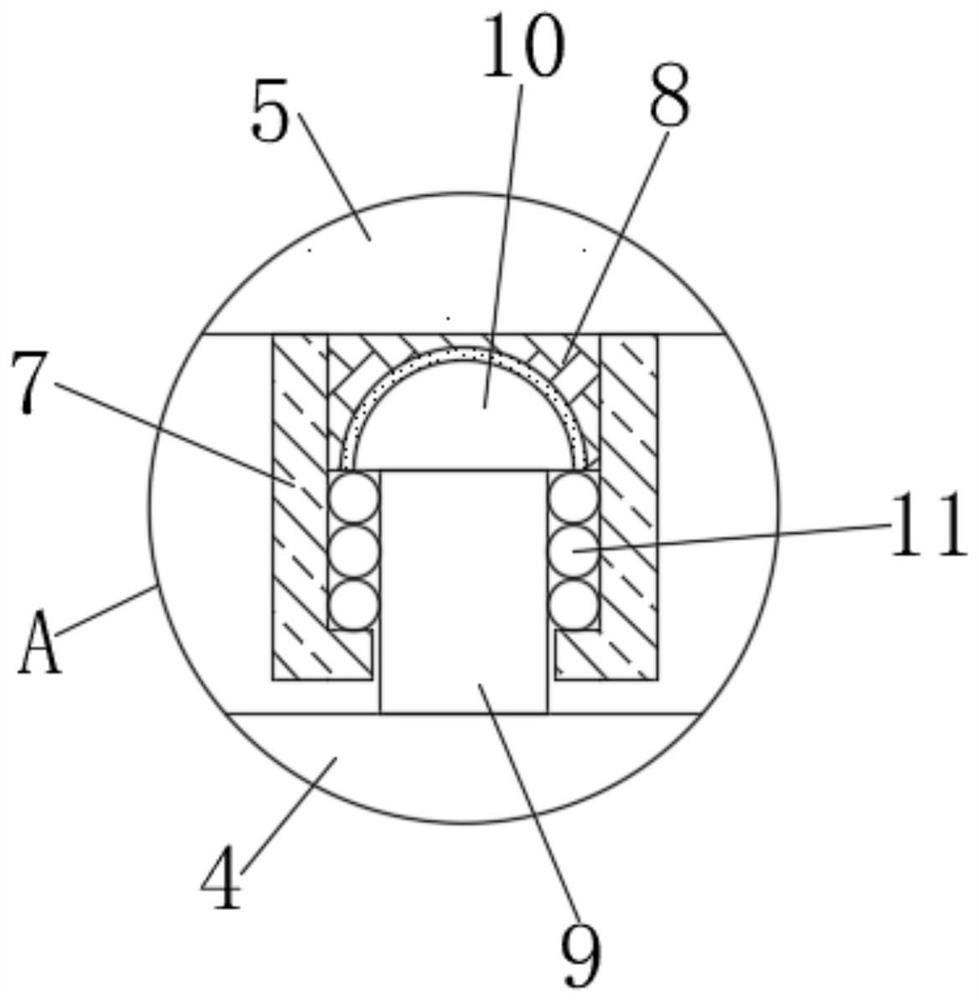

[0029] see Figure 1-2 , the present invention provides a technical solution: a long-chain branched PPH-loaded β-nucleating agent masterbatch, each component by weight: 70 parts of PP resin, 10 parts of PPH resin, 1 part of β-nucleating agent, hard 3 parts of fatty acid, 0.1 part of antioxidant, PPH resin is long-chain branched PPH, preferably Borealis WB140HMS, and the β nucleating agent is an organometallic salt nucleating agent, preferably NAB and NAB.

[0030] A method for preparing long-chain branched PPH-loaded β-nucleating agent masterbatch, comprising the following steps:

[0031] S1. Pour PP resin, PPH resin, β-nucleating agent, stearic acid and antioxidant into the mixing equipment in sequence. The mixing equipment is a vertical mixer, and the vertical mixer includes base plate 1 and base plate 1 Both ends of the top are fixedly connected with a support plate 2, and a tank body 3 is provided on the side where the two support plates 2 are close to each other. The up...

Embodiment 2

[0035] see Figure 1-2 , the present invention provides a technical solution: a long-chain branched PPH-loaded β-nucleating agent masterbatch, characterized in that, each component is calculated by weight: 75 parts of PP resin, 20 parts of PPH resin, β-nucleating agent 2 parts, 5 parts of stearic acid, 0.2 parts of antioxidant, the PPH resin is long-chain branched PPH, preferably Borealis WB140HMS, and the β nucleating agent is an organic metal salt nucleating agent, preferably NAB.

[0036] A method for preparing long-chain branched PPH-loaded β-nucleating agent masterbatch, comprising the following steps:

[0037]S1. Pour PP resin, PPH resin, β-nucleating agent, stearic acid and antioxidant into the mixing equipment in sequence. The mixing equipment is a vertical mixer, and the vertical mixer includes base plate 1 and base plate 1 Both ends of the top are fixedly connected with a support plate 2, and a tank body 3 is provided on the side where the two support plates 2 are c...

Embodiment 3

[0041] see Figure 1-2 , the present invention provides a technical solution: a long-chain branched PPH-loaded β-nucleating agent masterbatch, each component by weight: 80 parts of PP resin, 28 parts of PPH resin, 2 parts of β-nucleating agent, hard 5 parts of fatty acid, 0.3 part of antioxidant, PPH resin is long-chain branched PPH, preferably Borealis WB140HMS, and the β nucleating agent is an organometallic salt nucleating agent, preferably NAB and NAB.

[0042] A method for preparing long-chain branched PPH-loaded β-nucleating agent masterbatch, comprising the following steps:

[0043] S1. Pour PP resin, PPH resin, β-nucleating agent, stearic acid and antioxidant into the mixing equipment in sequence. The mixing equipment is a vertical mixer, and the vertical mixer includes base plate 1 and base plate 1 Both ends of the top are fixedly connected with a support plate 2, and a tank body 3 is provided on the side where the two support plates 2 are close to each other. The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com