Duplex stainless steel alloy and use of this alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]Good corrosion resistance properties as well a high ductility and toughness is obtained by the combination of elements in a duplex stainless steel alloy according to the invention. This steel alloy has also good workability, which enables for example extrusion to seamless tubes. The alloy according to the invention contains (in weight-%):

Cmax 0.03%SiMn 0-3.0%Pmax 0.030%Smax 0.050%Cr25-29%Ni5-9%Mo4.5-8% W0-3%Cu0-2%Co0-3%Ti0-2%Al 0-0.05%B 0-0.01%Ca 0-0.01%N0.35-0.60%

balance Fe and normal occurring impurities, wherein the ferrite content is 30-70 volume-%, and wherein each weight-% of Mo above may optionally be replaced by two (2) weight-% W.

[0025]Carbon (C) has limited solubility in both ferrite and austenite. The limited solubility implies a risk of precipitation of chromium carbides and the content should therefore not exceed 0.03 weight-%, preferably not exceed 0.02 weight-%.

[0026]Silicon (Si) is utilized as desoxidation agent in the steel production and it increases the...

PUM

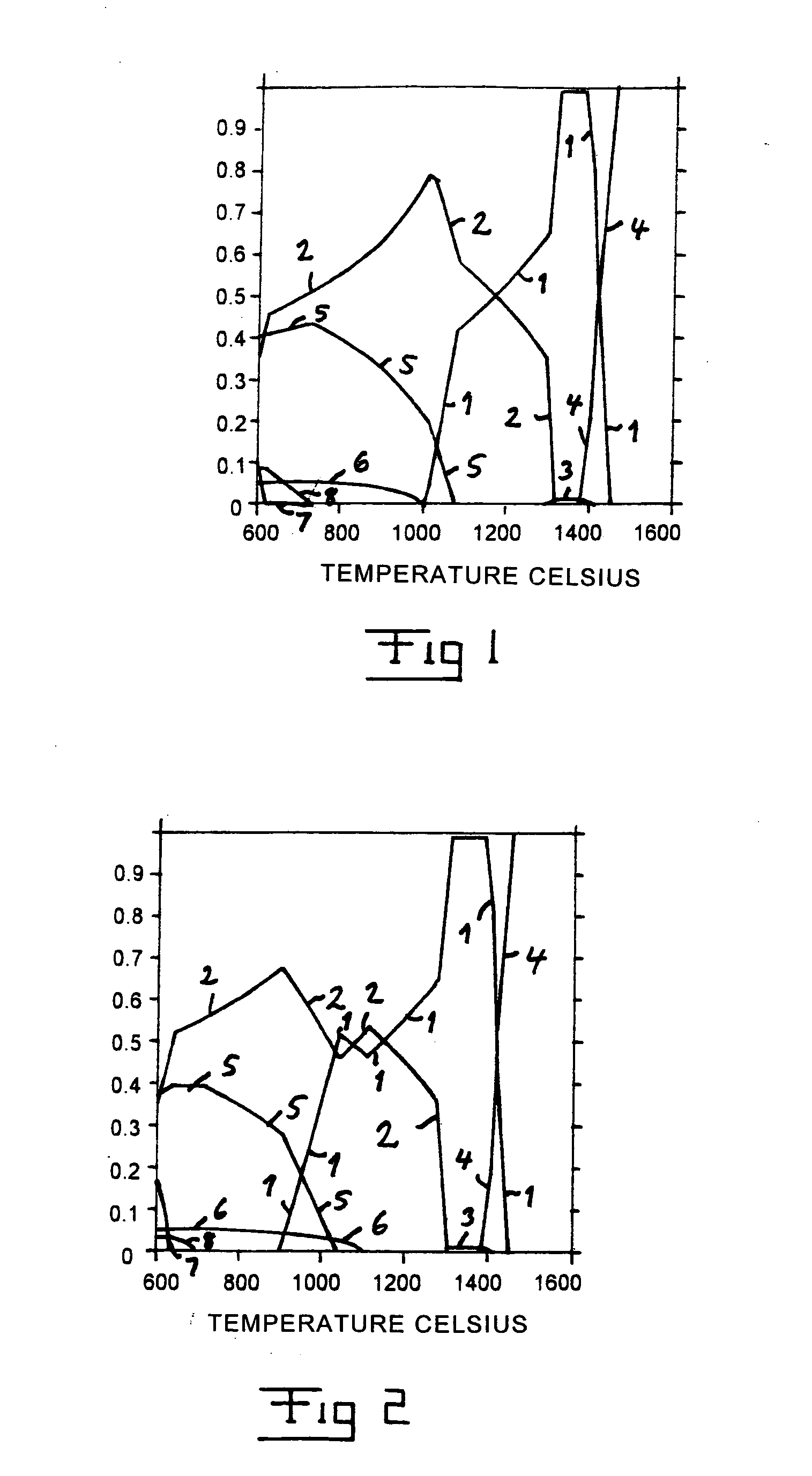

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com