A kind of reactive dye yellow and its preparation method and application

A technology of reactive dyes and disperse dyes, applied in the field of dyes, can solve problems such as unfavorable printing and dyeing enterprises' energy saving, emission reduction and clean production, affecting product quality and efficiency, color flower and vat difference, etc., and achieve good color fixing ability and high reactivity , avoid the effect of the use of soda ash

Active Publication Date: 2022-05-31

苏州澳缘盛新材料科技有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although the same color is good and the fastness is high, the process is lengthy and the energy consumption is too much, which is not conducive to energy saving, emission reduction and clean production of printing and dyeing enterprises, and as the processing time prolongs, there may be problems of color flower and cylinder difference in production , affecting product quality and efficiency

[0003] In order to solve these problems, many factories are exploring the one-bath one-step dyeing method of polyester and cotton. However, the existing reactive dye yellow still has a high temperature resistance difference, and can only be dyed at about 50°C, which is not suitable for one-bath one-step dyeing with disperse dyes. dyeing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0061]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

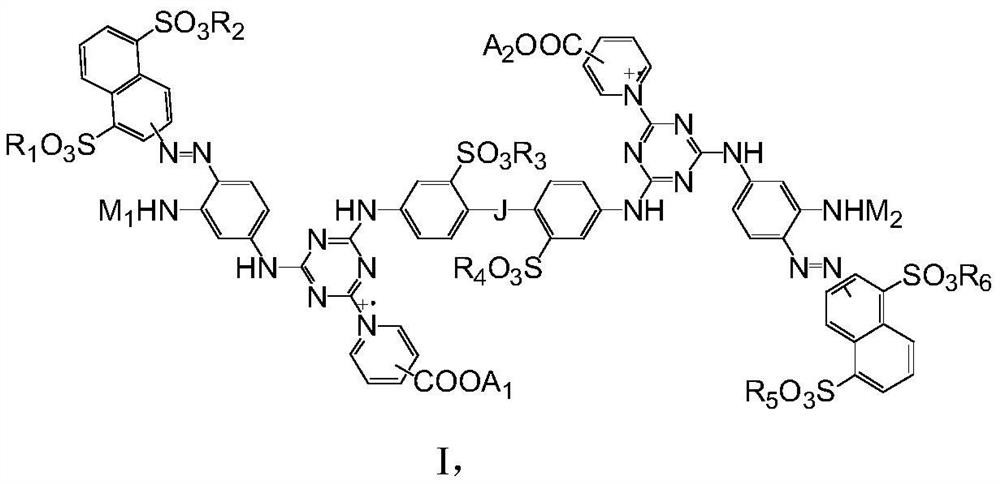

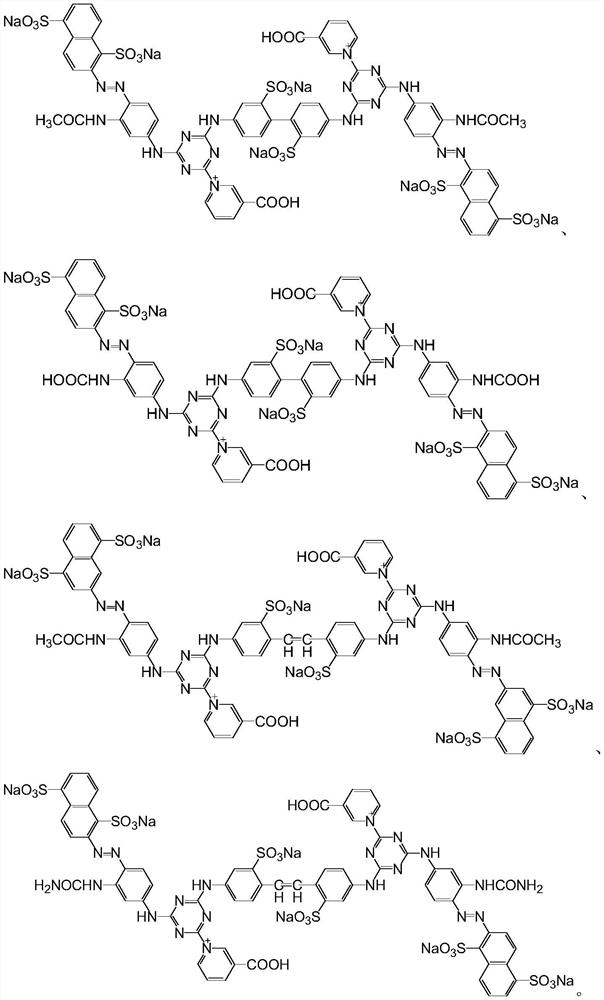

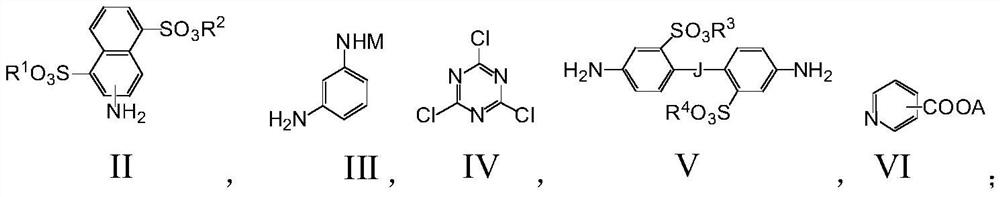

The invention relates to a reactive dye yellow and its preparation method and application. The compound structure of the reactive dye yellow is shown in the general formula (I): the reactive dye of the present invention has high reactivity, good color fixing ability and good Excellent dyeing ability, and the reactive dye of the present invention does not need to add soda ash to fix the color when dyeing, avoiding the use of soda ash. At the same time, the reactive dyes of the present invention also have high temperature resistance, and can be used in conjunction with disperse dyes to simultaneously dye T / R or T / C blended fabric products at a temperature higher than 100°C, realizing a one-bath dyeing process, which not only simplifies the dyeing process , Shorten the dyeing time, greatly reduce the amount of sewage, reduce labor costs and energy consumption.

Description

A kind of reactive dye yellow and its preparation method and application technical field The invention belongs to dye technical field, be specifically related to a kind of reactive dye yellow and preparation method and application thereof. Background technique When the polyester-cotton blended fabrics on the market are dyed at present, the commonly used dyeing method is the two-bath method, that is, first by dividing The fabrics are dyed with loose dyes, washed, and then dyed with reactive dyes, washed. Although the same color is better, the fastness is better However, the process is lengthy and the energy consumption is too much, which is not conducive to energy saving, emission reduction and clean production of printing and dyeing enterprises. It can cause color flower and cylinder difference in production, affecting product quality and efficiency. In order to solve these problems, many factories are exploring polyester-cotton one-bath one-step dyeing, but the exi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09B62/09C07D401/14D06P1/38D06P3/66D06P3/872

CPCC09B62/09C07D401/14D06P1/38D06P3/66D06P3/8252

Inventor 王高峰陆海英庄永祥陆再宏

Owner 苏州澳缘盛新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com