A processing method for improving the strength and plasticity of copper-containing titanium alloy

A technology of a copper-titanium alloy and a processing method, which is applied in the manufacturing field of copper-containing titanium alloy profiles, can solve the problems such as the decrease of alloy plasticity, the inability to obtain high-strength and high-plasticity titanium alloys, etc., and achieve the effect of improving the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

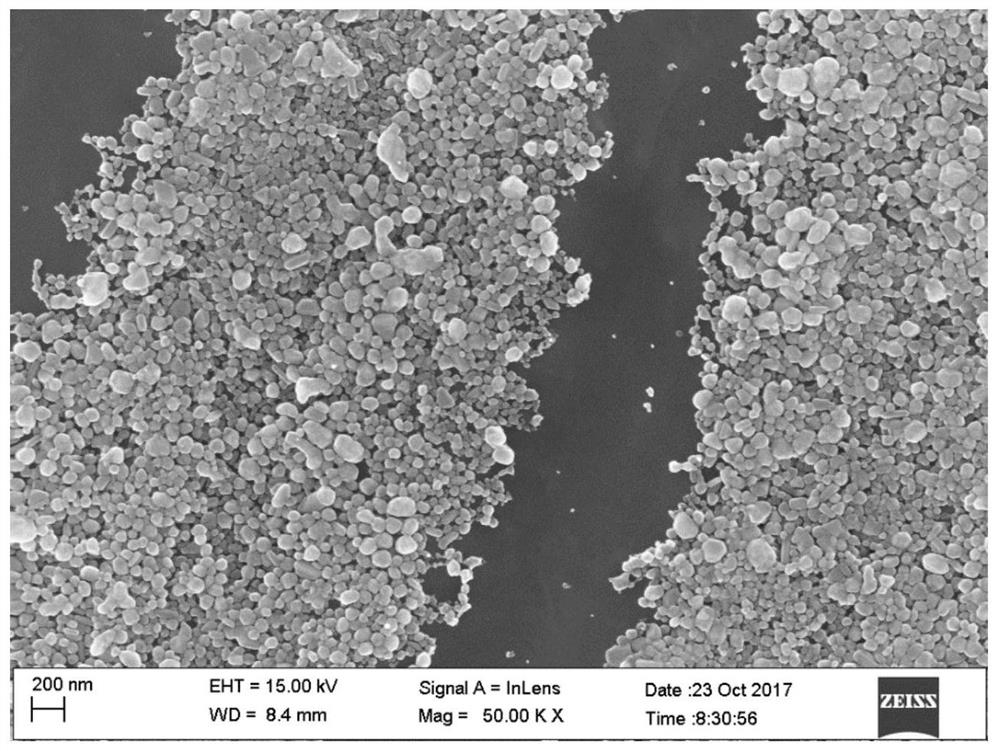

[0034]Copper-containing titanium alloys can be smelted according to the requirements of the composition design, and can be smelted and prepared into ingots by means of consumable electric arc furnace, induction melting or consumable electrodes. In order to achieve uniform alloy composition, multiple smelting can be used to ensure the macroscopic uniformity of alloy composition. Then, the hot-rolled deformation process is used to deform the experimental titanium alloy ingot into a bar or a plate. In this implementation example, the plate deformed to a certain thickness is selected as the original base material.

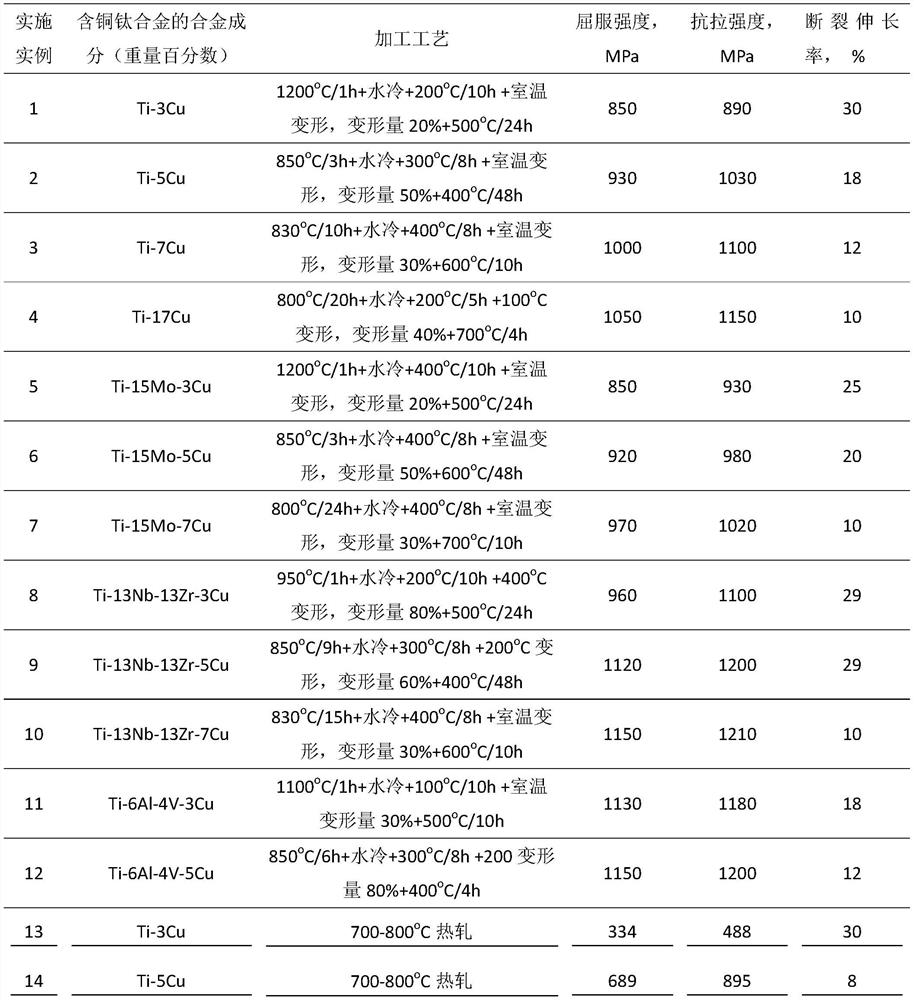

[0035] Then, the original base material was processed according to the process parameters described in Table 1 to form the experimental material. The tensile mechanical properties are in accordance with the national standard GB / T228.1-2010 metal material tensile test method, and the experiment is carried out on a calibrated tensile machine with a tensile speed of 1mm / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com