Stay cable lubrication maintenance device

A maintenance device and a technology for stay cables, applied in the field of stay cables, can solve the problems of high cost, high safety risk, and difficulty in maintenance, and achieve the effects of effective lubrication and maintenance, ensuring full contact, and being convenient for even smearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

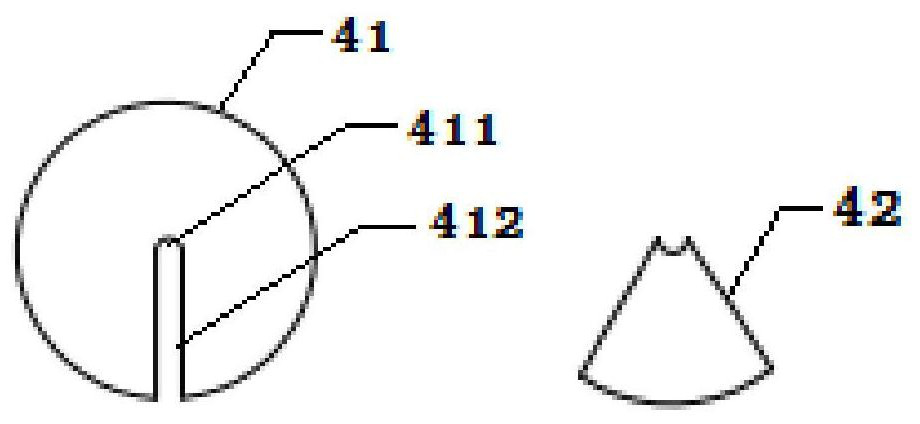

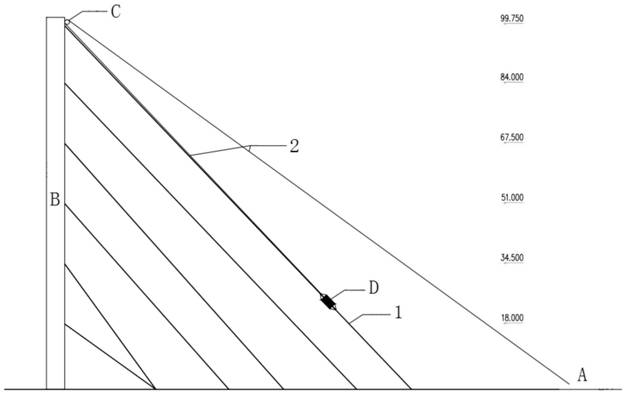

[0038] This embodiment provides a lubricating and maintaining device for stay cables, which includes a cylinder body 3 and a sealing cover assembly 4. Both ends of the cylinder body 3 in the axial direction and the sealing cover assembly 4 are equipped with Through holes, the shape of the cylinder body 3 can be square or circular and other cylindrical structures. The outer edge side wall of the sealing cover plate assembly 4 is in sliding contact with the inner wall of the cylinder body 3, preferably a dynamic sealing contact. 1. A chamber is formed between the side wall section of the cylinder body 3 and the sealing cover assembly 4 to accommodate the lubricating grease; The inner wall can be adapted. In order to realize the reciprocating dynamic sealing connection, a rubber sealing ring can be arranged on the outer edge side wall of the sealing cover assembly 4, so that the rubber sealing ring can be pressed against the outer edge side wall of the sealing cover assembly 4 an...

Embodiment 2

[0041] An improvement is made on the basis of Example 1, the cylinder 3 includes a cylinder wall and a cylinder assembly 5, and the cylinder 3 is designed to be a cylindrical structure; the cylinder assembly 5 includes a bottom plate 51 and a sealing plate 52, and the bottom plate 51 is detachably fixed At the bottom of the cylinder wall, the bottom plate 51 is a circular plate structure, and if it is fixed on the bottom of the cylinder wall by bolt connection, it realizes the opening and sealing of the bottom of the cylinder wall. The bottom plate 51 is provided with a through hole I511 and a slit I512 for passing the stay cable 1, and the slit I512 extends from the edge of the bottom plate 51 to the through hole I511 and communicates with the through hole I511; the sealing plate 52 is slidably arranged on the bottom plate 51 , used to cover the incision I512. If the sealing plate 52 adopts a fan-shaped plate structure, the inner arc section of the fan-shaped plate is close t...

Embodiment 3

[0046] Further improvement on the basis of Example 2, the top of the cylinder 3 is also provided with a cleaning part, the cleaning part and the smearing part move synchronously with the cylinder 3, and the cleaning part is used to clean the sundries on the stay cable, such as the oblique Aged, weathered grease and dust on the cables.

[0047] Optimized design, the smearing part adopts the sleeve bristle assembly II7, and the cleaning part adopts the sleeve bristle assembly I6. The sleeve bristle assembly II7 and the sleeve bristle assembly I6 have the same structure, and the mirror images are symmetrically arranged at both ends of the cylinder body 3 in the axial direction. The outer diameter of the sleeve bristles 10 is smaller than the outer diameter of the barrel 3, and the shape of the sleeve bristles 10 is circular.

[0048] Sleeve bristle assembly I6 all comprises sleeve bristle 10 and four pull rod members 11; Sleeve bristle 10 is used to be sleeved on the stay cable 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com