Oil-water separation structure for valve and implementation method thereof

A technology for oil-water separation and valves, applied in separation methods, valve housing structures, liquid separation, etc., can solve problems such as pollution, valves that do not have the function of oil-water separation, and oil-water mixtures that are not easy to separate and then discharged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

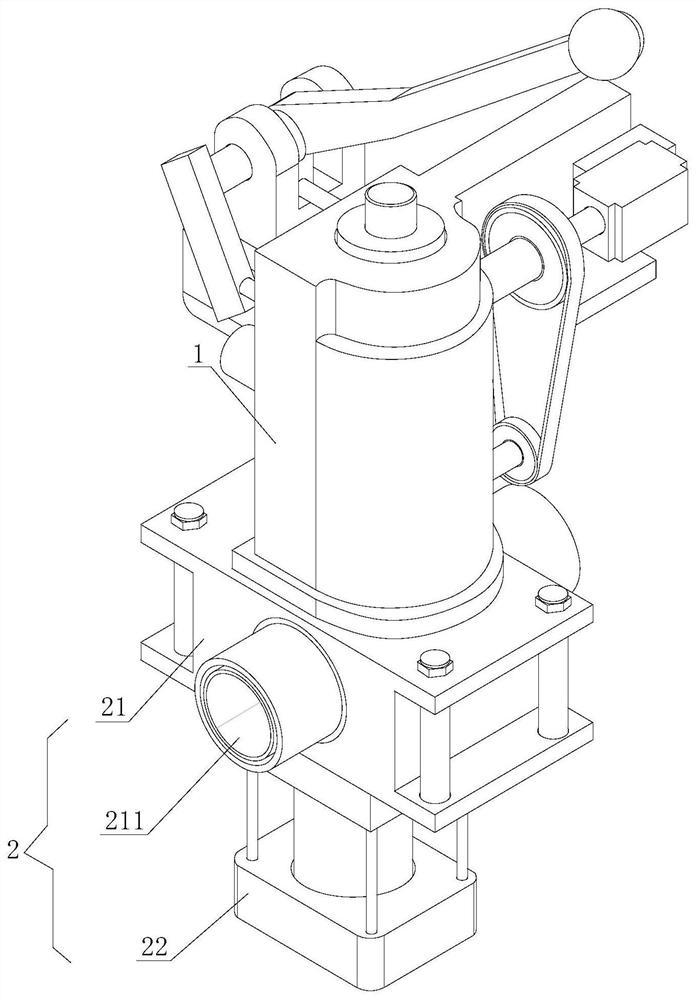

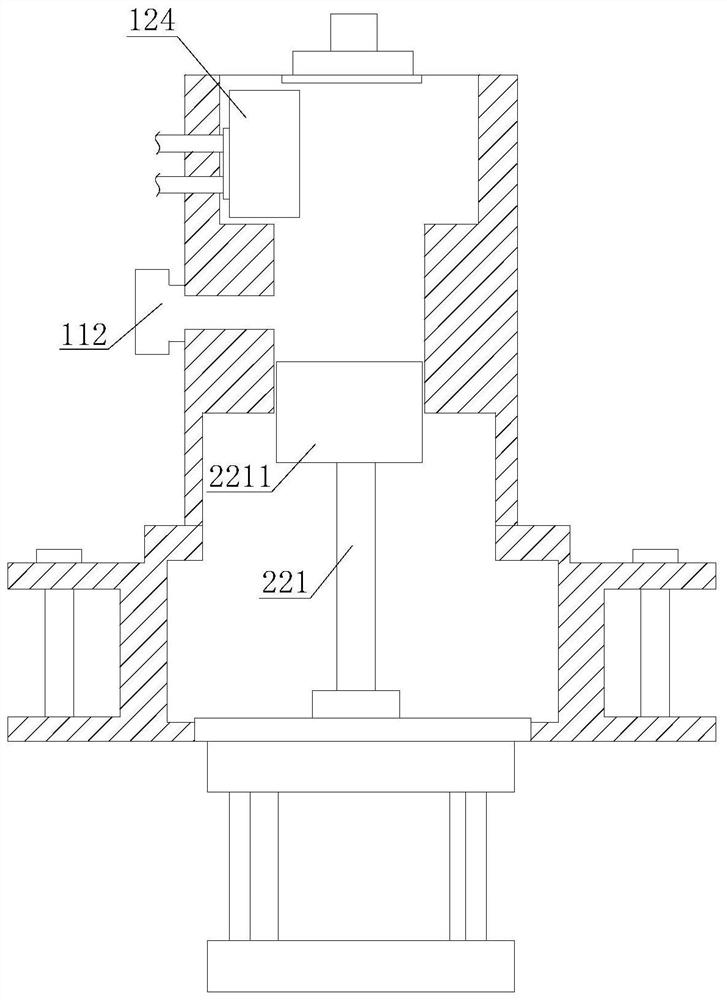

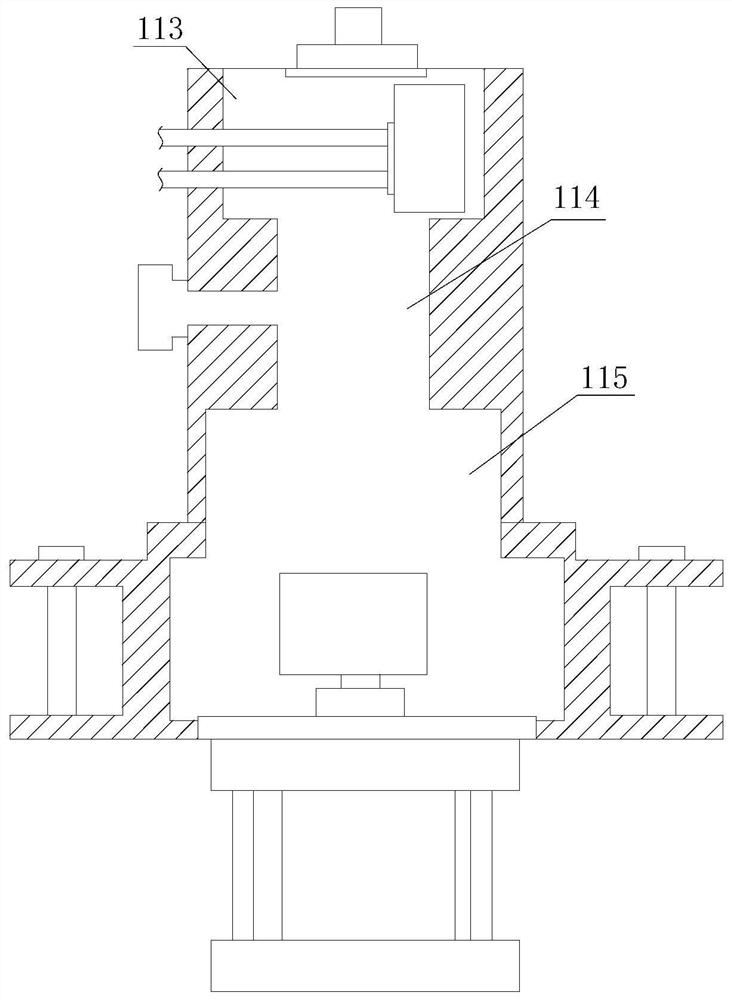

[0038] In order to better demonstrate the implementation process of the oil-water separation structure for the valve, this embodiment now proposes an implementation method for the oil-water separation structure for the valve, including the following steps:

[0039] Step 1: Open the rubber sealing plug 1111 and pour the oil-water mixture into the inner cavity of the valve body 11 through the liquid injection port 111, start the explosion-proof motor 13 at the same time, use the explosion-proof motor 13 to drive the rotating shaft 131 and drive the main drive wheel 141 to rotate at a high speed ;

[0040] Step 2: The main driving wheel 141 rotates at a high speed and drives the secondary driving wheel 142 to rotate synchronously through the roller belt 1411 connected to it, and the secondary rotating rod 1421 connected to one end of the secondary driving wheel 142 drives the folding roller knife 14211 to flow into the The oil-water mixture in the separation working chamber 115 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com