A kind of preparation method of copper mesh with oil-water separation function

A technology for oil-water separation and copper mesh, which is applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve problems such as reducing separation efficiency, and achieve the effects of simple process, simplified material processing steps and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of a copper mesh with oil-water separation function, comprising the steps of:

[0029] (1) Place the copper sheet to be processed in deionized water for ultrasonic cleaning for 30 minutes, the purity of the copper sheet is 99.99%, and the size is Φ26mm·0.1mm;

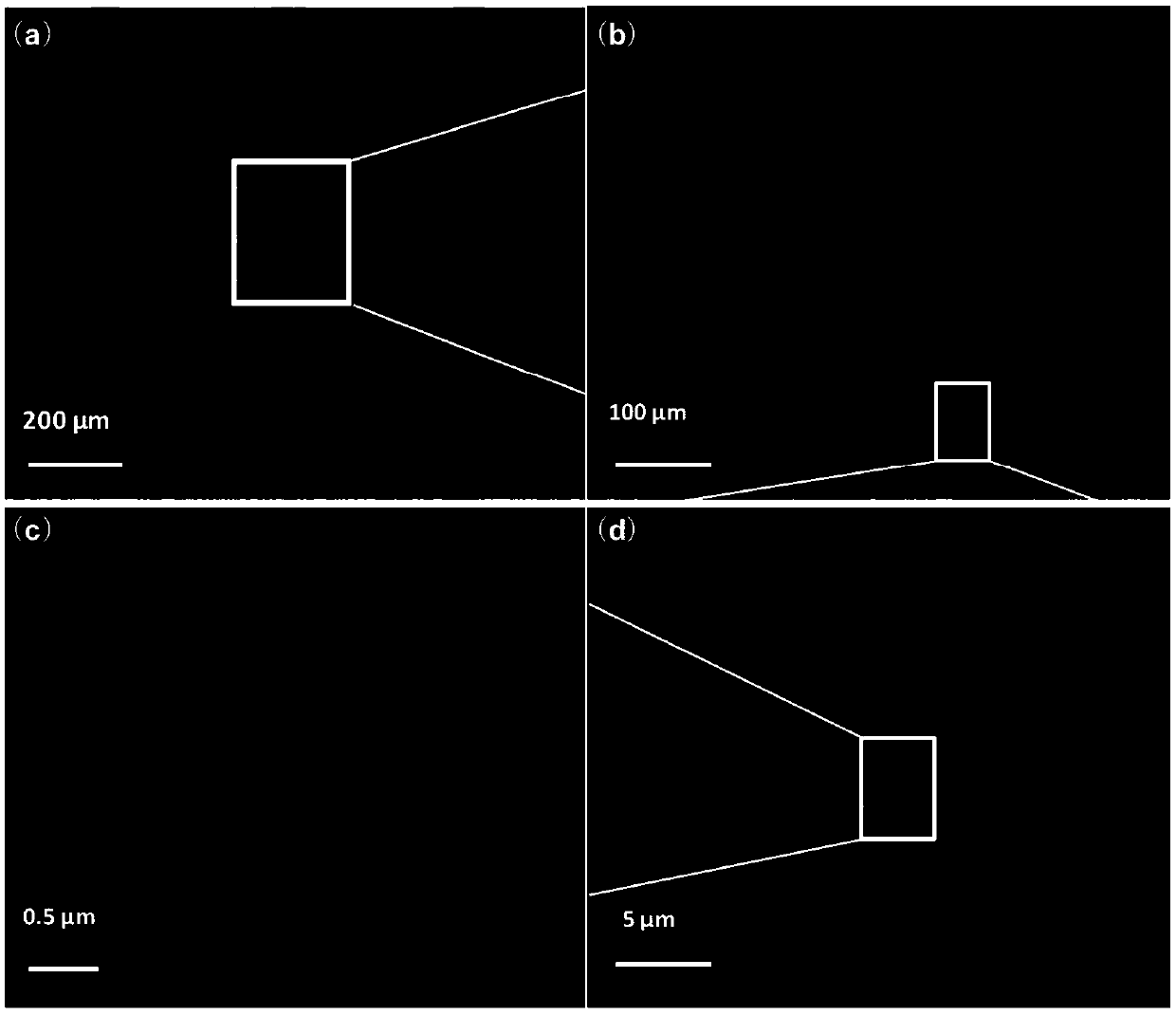

[0030] (2) Use pulsed fiber laser (wavelength 1064nm, pulse duration 100ns IPG: pulsed fiber laser produced by YLP laser) to ablate the surface of the copper sheet after step (1) cleaning, and construct a through-hole array with certain arrangement rules , the through hole is a square with a side length of 100 μm, and the distance between adjacent through holes is 300 μm; the parameters of the laser are: the laser focal length is 329 mm, the spot diameter irradiated on the surface of the copper sheet is 0.05 mm, and the power is 25W , the pulse repetition frequency is 20kHz, and the energy density is 63.66J cm -2 The laser processing area is limited to a square area with a side length of 13....

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com