Shear fork type suspension mechanism for tree barrier cleaning flying robot

A technology of flying robots and suspension mechanisms, which is applied to aircraft, unmanned aircraft, supporting machines, etc., to achieve good stability and safety, good structural rigidity and strength, and enhanced overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

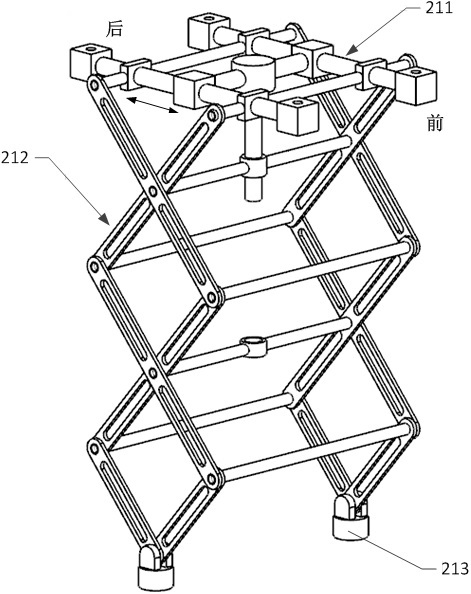

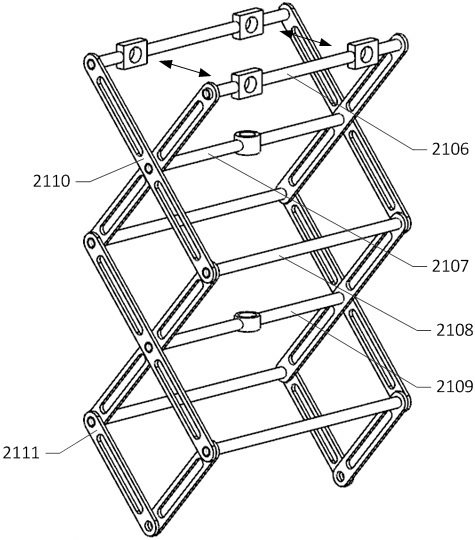

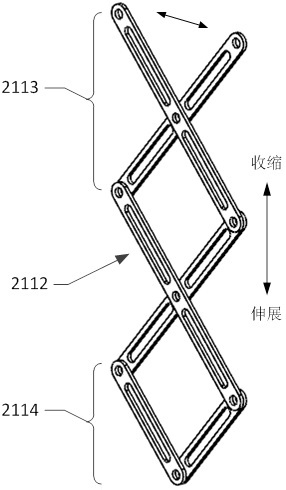

[0038] Embodiment 1: as Figure 1 to Figure 7As shown, a scissor-fork suspension mechanism for tree barrier cleaning flying robots is characterized in that: it includes a horizontally placed I-shaped frame 211, a telescopic device 212 articulated below the I-shaped frame 211, and a telescopic device 212 connected to The lower base 213 at the lower end and docked with the tool system 3; the I-shaped frame 211 includes a main beam 2101 located in the center and arranged transversely, and a pair of guide rods 2102 symmetrically fixed on both sides of the main beam 2101 and moving forward and backward 1. The flange seat 2103 that is located at the outer end of the guide rod 2102 and connected with the flight platform 1, the center of the main beam 2101 is equipped with a motor 2105, the output shaft of the motor 2105 is vertically downward and connected with the lifting screw 2104; the telescopic device includes left and right symmetrical A pair of scissor-fork assemblies 2112 arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com